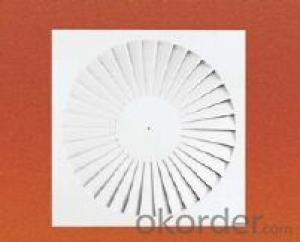

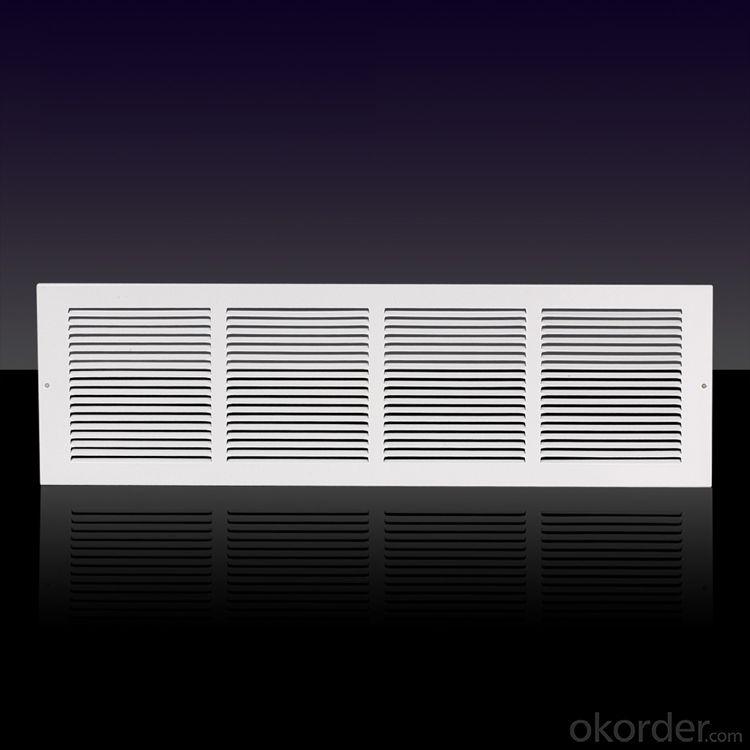

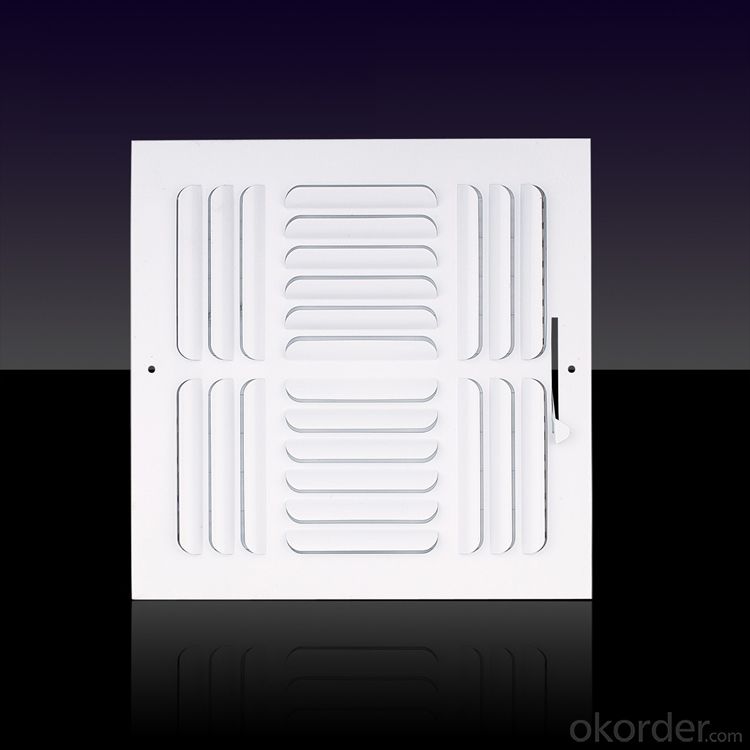

Deflection Air Grilles Ceiling & Sidewall Diffusers

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 999999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Air Diffuser

Steel Linear Slot Diffuser Air Grille

Supplying Air Diffusers

-Frame Thickness: 1.0mm /0.8mm

-Any Size be customed

-Powder Coated RAL 9010/9016

Usage of Air Diffuser

The grille is suitable for ceilling sidewall, soffit or cill mounting and may be used for supply or extract applications.

Typical installations include offices, shops, hotels and most commercial or industrial buildings.

Available as standard in white polyester powder coat finish.

Other polyester powder coat finishes are also available as an option.

Specification of Air Diffuser

1 | Item | HVAC aluminum air conditioner grille |

2 | Materials | Extruded Aluminum alloy (6063-T5) |

3 | Blade | Blades in 45°from aluminum profile or as customer’s requirements |

4 | Bar spacing | 30mm as standard or as customer’s requirements |

5 | Materials | 0.8mm, 1.0mm, 1.2mm, 1.5mm or according to the customers’ |

6 | Surface Finish | Powder coated, Anodized , PVDF, Mill finish. |

7 | Size | Width x Height, any sizes available |

8 | Powder for Finish | Environmental protection and non-toxic, and Color to keep 5 -10 years. |

9 | Color | Refer to RAL colors swatch or customized colors available |

10 | Design | Drawings designed according to the customers’ requirements |

11 | Payment terms | T/T, L/C, PYAPAL, etc. |

12 | Delivery time | Usual 15-20 work days for a 40GP container |

13 | Package details | Bubble wrap + Cartons for FCL, Bubble wrap + Cartons + Wood-box for |

14 | Mesh | Stainless steel security mesh, Aluminum security mesh |

15 | Type | Fixing and adjustable installation |

Products Show Of Air Diffuser

FAQ:

1, What's size do u have for round type diffuser?

A: We have face size from 150mm to 550mm,neck size from 250mm to 400mm

2, Do u still have other types ?

A: Yes, we have round diffuser/ rectangle diffuser/ linear grilles/ baseboard diffusers,etc

3, What's the most early delivery time?

A: Within 25 days for each 40'fcl

- Q:What are the differences and characteristics of D M type V compressor?

- f it is less than 1000 cubic meters / hour, you can choose D type, 2000 cubic meters or more, the best choice M type.

- Q:What is the function of the air conditioning condenser?

- At this point, the outlet temperature of the condenser is about 35~45 degrees C, and the optimum temperature is below 40 degrees C. The refrigerant then enters the expansion valve or capillary to cool down

- Q:What are the types of compressors?

- The liquid piston compressor is a rotary displacement compressor in which water or other liquid acts as a piston to compress the gas and then exhaust the gas

- Q:How to repair air conditioning compressor?

- The inspection results for the compressor power supply cord is damaged, the compressor terminal generally will rust, if simply replace the compressor wiring card terminals, due to poor contact, and the compressor when working current is large, easy to cause the fire, not a long time or will appear again the same fault, so when replacing the wiring card, must use sandpaper compressor terminal surface rust polished and clean.

- Q:What is the cause of the overload of the air conditioning compressor?

- Dust on the outside condenser can be cleaned, and the heat insulation cotton wrapped on the compressor can be removed

- Q:What is the function of the refrigeration compressor in the refrigeration system?

- The compressor is composed of a shell, an electric motor, a cylinder, a piston, a control device (a starter and a heat protector) and a cooling system. There are basically two starters, namely, heavy hammer and PTC. Among them, the latter is more advanced. There are two kinds of cooling methods: oil cooling and natural cooling

- Q:How to deal with the liquid hammer phenomenon of compressor

- If the compressor has occurred abnormal impact (knock or impact) sound, and will strongly shake vibration, indicating that the liquid is in the attack. Slight short term abnormal shocks may be of little concern, but often prolonged and heavy fluid shocks cause compressor deformation, rupture, and even breakage, which directly damages the compressor

- Q:How many types of drive are there in an air conditioner compressor?

- As a traditional refrigeration compressor, reciprocating refrigeration compressor is suitable for the refrigeration system with a wide range of refrigeration

- Q:What is the purpose of a two-stage compression refrigeration cycle?

- The traditional air conditioning system can only achieve the lowest heat at minus 7 degrees Celsius environment itself, and adopting the two-stage inverter air conditioner double stage compressor can be achieved in the limit condition minus 30 DEG C under strong heating

- Q:What are the parts of the outdoor unit?

- Start capacitor compressor refrigerant cycle for capillary tube respectively high pressure pipe and low pressure pipe

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Deflection Air Grilles Ceiling & Sidewall Diffusers

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 999999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords