Deer Guard Fence Netting/ Extruded PP Deer Guard Fence

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic netting plastic mesh breeding mesh

1. Plastic Plain Netting

Colour:white,black,blue and green, client's requirement.

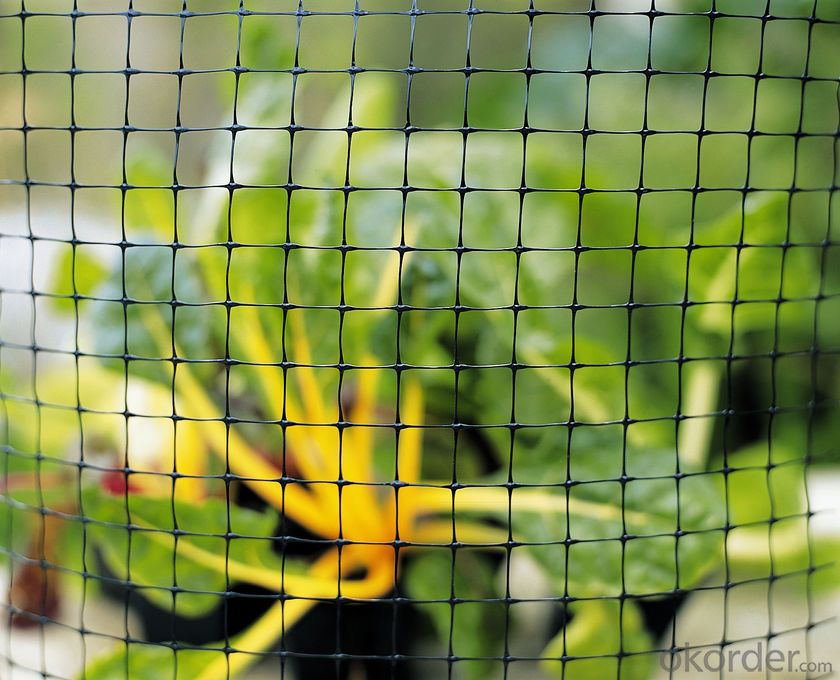

2. Deer fence introduction:

Deer fencing is a very high strength, lightweight, 3.6ft to 7.3ft high deer fence manufactured from high strength polypropylene BOP plastic netting. Deer have a tendency to forage over large areas and the cost effective deer fencing offers a very effective deer control barrier.

The deer fence is black, UV stabilised and rot proof and unobtrusive as it merges into it's background. Deer fencing is very quick and easy to erect and each roll weighs less than 15kg. The Deer Netting should be installed by battening to the fencing posts to ensure the mesh filaments are not damaged.

3. Features of the deer neeting fence:

Deer fence is easy to erect and install

Plastic netting has a mesh hole size of 0.06" ,0.08",0.18",0.19"

The BOP plastic netting has a high tensile strength

Plastic mesh is UV stabilized and chemical resistant

Deer fencing rolls are lightweight

Deer fencing is a very high strength, lightweight 1.8m high Deer fence manufactured from polypropylene.

Deer fencing net is supplied on a 100m long roll

4. Features:

1). Low cost, while has superior strength

2). Has anti-tearing and friction capability

3). Wide range of product availability, some other mesh sizes and weights can also produced as per customers' requirements.

5. Package/Payment/Delivery:

Package: Usually packed by rolls in plastic film bags with labels inside and then loosely loaded in the container

6. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Waiting to cooperate with you!

- Q:Can geotextiles be used in riverbank stabilization applications?

- Yes, geotextiles can be used in riverbank stabilization applications. They are commonly used to prevent erosion and provide stability to riverbanks by reinforcing the soil and preventing sediment movement.

- Q:What are the factors to consider when selecting geotextiles for embankment stabilization?

- When selecting geotextiles for embankment stabilization, there are several important factors to consider. These include the strength and durability of the geotextile, its filtration and drainage properties, its compatibility with the soil and other materials, and its ability to withstand environmental conditions such as UV exposure and chemical exposure. Additionally, factors such as cost, installation requirements, and project-specific needs should also be taken into account.

- Q:Now geotextile price quota how?

- 2017 geotextile price cheaper than last year, the current price of raw materials is relatively stable production. Geotextile classification of many, you ask more general, so no way to give you a detailed offer. Different technical requirements are uneven prices, but the overall price has come down, and is now the lowest price since 2017.

- Q:Can geotextiles be used in landscaping?

- Yes, geotextiles can be used in landscaping. Geotextiles are commonly used in landscaping projects as a way to control erosion, stabilize soil, and prevent weed growth. They are particularly useful in areas where there is heavy rainfall or sloping terrain, as they help to retain soil and prevent erosion. Additionally, geotextiles can be used to separate different layers of soil, provide drainage, and reinforce structures such as retaining walls.

- Q:Do you want to put the geotextile and the impounded vegetables in the soil?

- No, I am specializing in the production of geotextile materials

- Q:What are the factors to consider when selecting geotextiles for coastal protection projects?

- When selecting geotextiles for coastal protection projects, there are several factors to consider. Firstly, the type and quality of the geotextile material is crucial. It should be durable, resistant to UV radiation, and capable of withstanding the harsh coastal environment, including exposure to saltwater and strong waves. Secondly, the intended function of the geotextile should be taken into account. Different geotextiles offer varying levels of erosion control, filtration, and stabilization. Therefore, the specific needs of the coastal protection project, such as preventing beach erosion or stabilizing coastal structures, should be considered. Thirdly, the site conditions and project requirements play a significant role. Factors like wave energy, sediment characteristics, and slope stability need to be assessed to determine the appropriate geotextile specifications. Furthermore, the installation and maintenance requirements should be evaluated. Geotextiles that are easy to install and require minimal maintenance are often preferred, as they can save time and costs during the project's lifespan. Lastly, the cost-effectiveness and longevity of the geotextile should be taken into consideration. It is essential to balance the initial cost of the geotextile with its expected lifespan and performance to ensure a sustainable and economical solution for coastal protection.

- Q:What are the considerations for geotextile selection in coastal engineering projects?

- When selecting geotextiles for coastal engineering projects, several considerations need to be taken into account. First, the geotextile should have a high tensile strength and durability to withstand the harsh coastal environment, including wave action and fluctuating water levels. It should also possess excellent filtration properties to prevent the migration of fine particles while allowing water to pass through. Additionally, the geotextile's permeability and hydraulic conductivity should be considered to ensure proper drainage and avoid the buildup of hydrostatic pressure. The material's resistance to biological degradation and UV radiation is crucial for long-term performance. Lastly, the geotextile should be compatible with the surrounding materials and easy to install and maintain, minimizing disruptions to the coastal ecosystem and reducing overall project costs.

- Q:What are the key factors affecting the clogging behavior of geotextiles?

- The key factors affecting the clogging behavior of geotextiles include the particle size and gradation of the soil or other material being filtered, the permeability and porosity of the geotextile, the hydraulic loading conditions, the presence of fines or clay particles in the soil, and the duration of exposure to clogging agents. Other factors such as the geotextile's physical and chemical properties, the presence of biological organisms, and the maintenance practices also play a role in determining the clogging behavior.

- Q:Roof 1: 3 cement mortar leveling layer mixed with polypropylene or nylon-6 fiber is the role of what?

- Compensated shrinkage, to prevent cracking, from a certain role in the tensile polypropylene fiber with high strength, good toughness, chemical resistance and microbial resistance and low price advantages, it is widely used in ropes, fishing nets, seat belts, luggage , Safety nets, sewing thread, cable foreskin, geotextile, filter cloth, papermaking felt and paper reinforced materials and other industries. Polypropylene woven geotextiles made of polypropylene fiber with high strength, acid resistance, alkali resistance, antimicrobial, wet and wet strength and other excellent properties can be used to build civil engineering (such as dams, reservoirs, highways) , Railways, etc.) play a reinforcement role, and the load load evenly distributed in the geotextile, so that the roadbed settlement evenly, reducing the ground crack. Construction of slopes, the use of woven polypropylene geotextile can stabilize the slope, reduce the collapse of the slope, shorten the construction period, to extend the service life of the slope. When carrying a larger load, we can use woven geotextile and nonwovens as the matrix of composite geotextile. Polypropylene fiber can be used as concrete, mortar and other filler material to improve the impact resistance of concrete, waterproof insulation.

- Q:Are geotextiles resistant to fungal growth?

- Yes, geotextiles are generally resistant to fungal growth due to their synthetic nature and non-biodegradable properties. This resistance helps maintain their structural integrity and effectiveness in various applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Deer Guard Fence Netting/ Extruded PP Deer Guard Fence

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords