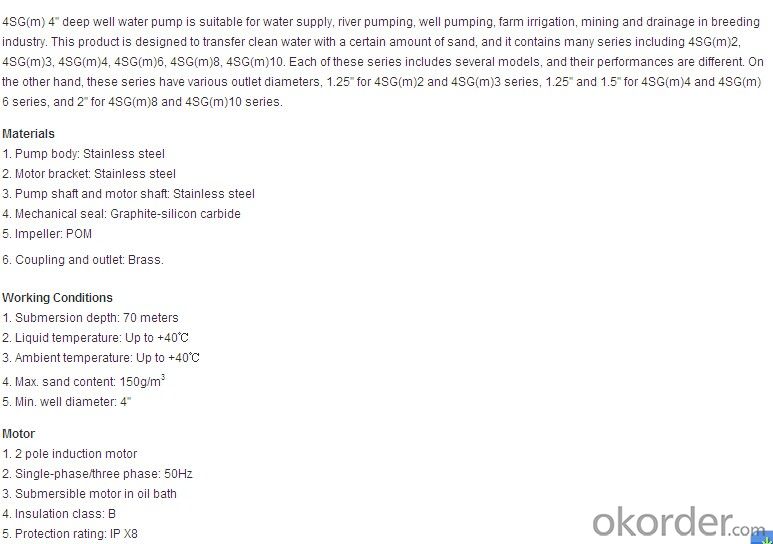

Deep Well Pump 4SG(m) 4"

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:I have a cabin cruiser and I recently took it out of storage and had it de winterized. Now everything seems to work except for the fresh water pump for the sink, shower and toilet. Does this type of pump need to be primed? If so how do you prime it? Thank you for the help.

- Those pumps are usually self priming.. either you have a PLUGGED LINE or the water pump froze in the cold and it needs to be replaced... but they are cheap.

- Q:I have 2000 ford ranger v6 3.0 I replaced the water pump ten months ago and all of a sudden it's running hot it only runs hot when I stop for a second at a red light or stop sign. I changed the radiator today but still is running hot. The top radiato hose going to the thermostat housing is building a lot of pressure and the water is bubbling in the reservoir what could be wrong? And I took the thermostat out last week

- 2000 Ford Ranger Water Pump

- Q:How do the water pump work please till me water pump mechanism?

- the international is produced from persons, and we've a lifetime to stay. this is our getting at the same time, our sharing and our helping that are the main important factors of life. So, clearly this must be finished between people, and prefer the brook, people come and persons bypass, yet we bypass on living. this is that this interplay it particularly is the objective of life, and finally as quickly as we are nearing our end there are in straight forward terms some left, some who count on us.

- Q:changed the thermostat. it overheats but cools down a heat bar or two idling at stoplights. i filled up the coolant reservoir when i changed the thermostat, drove it about 2 miles(engine was already up to temp when i started) and it overheated. drove it two miles back going about 35-40 and it never went above normal but was still overheating. checked the reservoir and it was empty. stuffed a hose in it and plugged it up with a towel to force water in to see if it was leaking anywhere, no leaks. while running with the rpms up the top hose is easy to squeeze. makes me think water pump. but if i go over 45 it over heats makes me think clutch fan.

- So if i understand, you are losing water from your system but no evidence of where it is going. I can think of two options. Heater core, but you may get a coolant smell inside the car, steam on the interior of windshield. You can check this by connecting the heater hoses directly, bypassing the heater core. If it still loses water, look for foamy oil on the dipstick or on the oil filler cap. If present then the other guy is right - headgasket. I would also look into flushing the system, or replacing the radiator - it may be clogged.

- Q:The water pump is bat on the car I have. I have the part but I need to know if I should have someone install it for me or could I do it myslef. I heard it the timing may be messed up after the pump is in

- if you have never did it before ,yes its a pretty hard job to do,and there's more involved than just replacing the pump on it,one thing that might help you is to get a repair manual on the car ,they are very helpful and give tips on how to do it right and not have to do it over again,for someone who has never done this before though and doesn't have the right tools its a pretty hard job,good luck.

- Q:need lincoln 01 water pump and radiator do 2000 parts fit an 01?

- never okorder and type in your data. hit radiator. click on product and hit the compatability button. if its the same, it will be listed almost surely.

- Q:Hi,My problem is of this automatic water pump ,it is disrupt always I don't no why..I also want to knew what is the function of the pressure air tank??? The picture is here:

- WHAT does it is disrupt always really MEAN?? OK, that said... pumps such as this work to maintain a pressure with two set points even though the regulator only has one indicated.. The lower set point which as pressure drops, the pump turns on, and the upper set point where when the pressure rises to that point, the pump shuts off. When the pressure drops to the lower set point, it triggers the pump to run. When the pressure rises to the upper set point, the pump turns off. If the set point is 50 pounds, it may turn on at 47 and off at 53, or the window could be smaller and on at 49 and off at 51. The air bladder works as a shock absorber, just as the shocks work in your car to smooth the ride. When the pump turns ON there is a pressure pulse that without the air space, would promptly turn the pump off again. This is called short cycling and will cause your pump to on-off-on-off-on-off rapidly. The solution is to refill the air bladder. People with well pumps instead of city water have this problem frequently as the air bladder loses the bubble and does not work as a spring or shock absorber. I have city water NOW, but I used to use a well (which is still operational if I choose to use it) and I experienced pump short cycling the very first year I bought the house. The thing IS, I was ignorant. I missed the thing about a well and a septic tank that also uses a pump to an above ground drain field. YES. I was STUPID because I had NOT paid attention. NOW, years later, I have learned, the HARD way mind you, how these sanitary systems WORK in real life in RURAL America....

- Q:I have a 94 Mazda b2300 it was working great last week then all the sudden it started making a knocking sound and started to overheat! Its still drivable but it overheats if i go far! A friend told me it can be the Water Pump so i put a new one, I was told it can be the Thermostat so i had a new one put in. It worked for awhile but began overheating again. My truck is my livelihood so its important i get it fixed! I cant afford a mechanic but just asking to see if anyone knows what it could possibly be? It catches good and the engine sounds strong but it keeps overheating!

- 94 Mazda B2300

- Q:I need a water pump for a 1930 Chrysler Roadster and have no idea where to get one. Any suggestions?

- No personal experience, but it is a start, try below linkage. I just Googled 1930 Chrysler Roadster

- Q:i have a 1996 infiniti i30t and its leaking from underneath the car so i took it in to get it diagnosed and they said i need a new water pump and they are trying to charge me 500 dollers and if i need a new timing belt i have to pay a 1000 dollers. is there a cheaper way i can fix my car. it started to over heat today and this sucks cause its my only car my parents wont buy me a new car so im stuck with this stupid old car and i have to pay for it they wont help me. can someone help me?

- You need more estimates - those prices are way (!!!!!) overpriced; keep a gallon jug of water with you at all times and check the radiator fluid level when the engine is cold [NEVER when hot] and get 3 - 5 estimates from different garages

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Deep Well Pump 4SG(m) 4"

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords