Deep Drawing Aluminium Circles HR AA5052 0.2mm-2mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

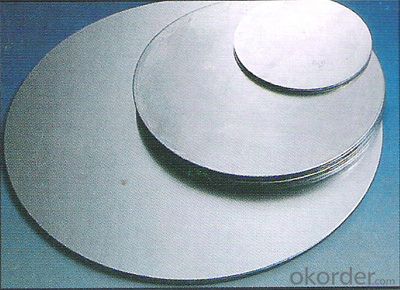

1.Structure of Deep Drawing Aluminium Circle

Deep Drawing Aluminium Circle is one semi-finished aluminium material. Aluminium Circle is widly used cookware, for example, aluminium pot, aluminium pan, aluminium cup ect. Our aluminium circle are widly exported to African market. We export more than 2000 tons every month. We can assure the breakage rate below 5%. Extra breakage will be responsible by our company.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Thickness | Diameter | Weight | Style |

| AA5052 | 0.2MM-2MM | 100MM-1000MM | 2 TONS | DEEP DRAWING |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 2 tons.

- Q:What are the different methods of joining aluminum sheets?

- There are several methods of joining aluminum sheets, including welding, adhesive bonding, mechanical fastening (such as riveting or screwing), and clinching. Each method has its own advantages and considerations, depending on the specific application and desired outcome.

- Q:What paint is better to paint on the brushed aluminum sheet? Simple process and good adhesion!

- As long as it is spray paint, adhesion is not the same, if you want to firm, it is better to paint

- Q:Can aluminum sheets be used for architectural applications?

- Architectural applications can definitely make use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages for architectural projects. It possesses durability, resistance to corrosion, and the ability to withstand extreme weather conditions, making it an ideal choice for different architectural applications like roofing, cladding, facades, windows, doors, and decorative elements. The availability of aluminum sheets in various thicknesses, finishes, and colors allows architects and designers to achieve their desired aesthetic while maintaining structural integrity. With the material's flexibility in being easily shaped, bent, and formed into complex designs, architects are provided with creative freedom and flexibility. Aside from its aesthetic appeal, aluminum is also an environmentally sustainable choice for architectural applications. It is highly recyclable, contributing to a high recycling rate and promoting eco-friendly options. The use of aluminum sheets in architectural projects helps in reducing the carbon footprint and promoting sustainable design practices. Moreover, aluminum sheets offer excellent thermal and acoustic properties that contribute to energy efficiency and sound insulation in buildings. The material aids in reducing energy consumption and enhancing occupant comfort, making it an attractive option for architects and building owners. In conclusion, the versatility, durability, sustainability, and aesthetic appeal of aluminum sheets make them a popular choice for architectural applications. They provide numerous benefits and can be utilized in various ways to create stunning architectural designs while ensuring long-lasting performance.

- Q:What is the weight of the aluminum sheets?

- The weight of aluminum sheets may differ based on their size, thickness, and density. To calculate the weight accurately, one must possess the dimensions and density values specific to the aluminum sheets under consideration.

- Q:Can aluminum sheets be used for insulation purposes?

- Yes, aluminum sheets can be used for insulation purposes. Aluminum has a high thermal conductivity, which means it is a good conductor of heat. However, when used for insulation purposes, aluminum sheets are typically combined with other materials to create a more effective insulation system. One common example is aluminum foil insulation, where a layer of aluminum foil is combined with other materials such as foam or fiberglass to create a barrier against heat transfer. The reflective properties of aluminum also make it useful for reflecting radiant heat, further enhancing its insulation capabilities. Overall, while aluminum sheets alone may not provide sufficient insulation, they can be used effectively in combination with other materials to create insulation systems for various applications.

- Q:Can aluminum sheets be used for architectural facades?

- Yes, aluminum sheets can be used for architectural facades. Aluminum is a lightweight and durable material that is commonly used in construction due to its corrosion resistance and versatility. It can be easily shaped, cut, and formed into various sizes and designs, making it suitable for creating aesthetically pleasing architectural facades. Additionally, aluminum sheets offer excellent weathering properties, low maintenance requirements, and can be finished with different coatings to enhance their appearance and protection against environmental elements.

- Q:How to clean the engine oil and kerosene on the surface of aluminum sheet?

- You can clean it with detergent of carburetor, and buy it in auto accessories shop.

- Q:Can 101 aluminum sheets be anodized?

- Yes, 101 aluminum sheets can be anodized. Anodizing is a process that creates a protective oxide layer on the surface of aluminum, enhancing its corrosion resistance and durability. It can be applied to various grades of aluminum, including 101, to achieve desired finishes and provide additional protection. Anodizing can be done through various methods, such as chromic acid anodizing, sulfuric acid anodizing, or hardcoat anodizing, depending on the specific requirements and desired results. Therefore, 101 aluminum sheets can certainly undergo anodizing processes.

- Q:Are aluminum sheets resistant to chemicals?

- Yes, aluminum sheets are generally resistant to a wide range of chemicals.

- Q:I have to repair a cracked aluminum engine block. What alumunum epoxy should I use?

- Best Epoxy For Aluminum

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Deep Drawing Aluminium Circles HR AA5052 0.2mm-2mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords