Decking Wpc Outdoor with SGS and CE from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Decking Wpc Outdoor

| Name | JWPC decking |

| Type | SMX150H134 |

| Size | W*H=150*134 mm |

| Length | 1500mm, 1800mm, 2000mm, Customized |

| Material | Wood Powder, HDPE, Additives |

| Surface Finishing | Sanding, Brushing, Wood grain |

| Certification | CE, Reach, Intertek, SGS, ISO, FSC |

| Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

This Profile is JUFENG WPC decking, WPC flooring, Outdoor decking, Swimming pool decking, Composite deck.

--Elegant nature wood grain texture and touch with wood scent

--Elegant and detailed shape design

--No cracking, warping and splitting

--Water-proof and erosion-proof

--Environmental friendly and no other hazard chemical

--Safe to use for many years

--Low maintenance and no painting

--Carpenter oriented and friendly easy installation

--Dimension stability against moisture and temperatur

--UV resistance

Main Features of Decking Wpc Outdoor

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

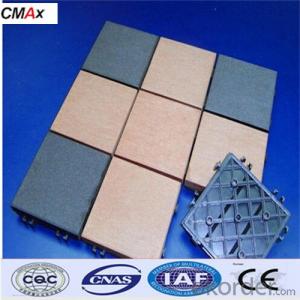

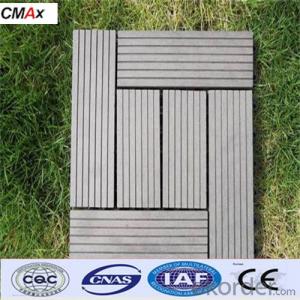

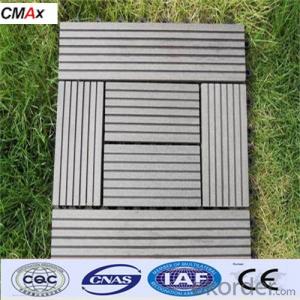

Picture show of Decking Wpc Outdoor

Specification of Decking Wpc Outdoor

Name | Decking Wpc Outdoor |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

FAQ of Decking Wpc Outdoor

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q:Technology of plastic floor

- 1, ground Flatness: requirements within 2 meters ruler flatness should be less than 2mm-3mm.2, hardness: base surface hardness of not less than 1.2 mpa.

- Q:What plastic floor

- Light weight: weight after construction. After the construction of lightweight wooden floors than 10 times than the ceramic tile construction light weight 20 times than stone construction after 25 times of light weight, the utility most suitable for high buildings, three floors above the office building etc.. Reduce the bearing capacity of the building, safe, and convenient handling.

- Q:Plastic floor joints how to deal with?

- Cold welding: when the plastic floor laying is completed, the use of cold liquid, cream or cold welding to connect floor seam.

- Q:How many yuan per square meter of plastic floor

- Please understand Shanghai Hu Mei plastic floor for the sports ground facilities, good floor to prevent injuries, foot comfort. Shanghai, Shanghai, the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and the United States and. Stable regular rebound to the ground to achieve the best comfort

- Q:Plastic floor, is expected to invest much capital investment

- From the major categories, new building materials products include refractories, lightweight building materials, waterproof building materials and insulation materials.

- Q:Plastic floor gap can be used to do plastic glass

- Buy plastic floor is a choice of material, how to install the plastic floor, plastic floor price, how much money the plastic floor, Shanghai plastic flooring, plastic flooring manufacturers, professional plastic floor, Fuzhou plastic floor, plastic floor thickness, plastic floor of environmental protection, Hangzhou plastic floor, size of plastic flooring, plastic flooring specifications, plastic floor how much money Nanjing Hefei Yiping, plastic floor, plastic floor

- Q:The advantages of plastic floor tile

- Plastic floor is another name for PVC flooring. The main component of PVC material, PVC floor can be made into two kinds, one is homogeneous, is from the bottom to the pattern material is the same. There is a composite type, is the top layer is a pure PVC transparent layer, the following with the printing layer and foam layer. "Plastic floor" refers to the use of polyvinyl chloride materials production floor. PVC floor is widely used in all aspects of home and business because of its rich color and variety of colors.

- Q:You master the family, to help me, I do not care about the color of plastic bags on the floor tiles, and how to rub are not wiped out, please help me master, I will add the score

- 7, ink, cement and other pollutants using hydrochloric acid, nitric acid and other dilute solution.8, paint, paint and other pollutants using special cleaning agent.

- Q:PVC plastic floor development trend?

- So PVC plastic floor is not a gap in china. China's sports flooring design, production and sales, quality supervision and other aspects of the lack of systematic and comprehensive national standards, in the absence of a unified system of national standards, enterprises lack of coordination, it is very difficult to carry out the management of the industry. However, although the problem is still a lot, but with the increasing emphasis on people's physical health, and its huge business opportunities are also highlighted.

- Q:Shop: composite floor below the moisture with plastic mold moisture do?

- The second is ground mat. The mat is composed of a layer of plastic film and polyethylene foam bonding, and this layer of film thickness and toughness of the material is very good, is not an ordinary plastic film, so I know if the laying of the floor directly on the ground, direct contact is no problem, the moisture in the floor around the room floor expansion joint direct release, so there is no problem of ventilation, also to cushion the plastic film surface is generally relatively thick, so it will not easily deteriorate, generally do not have what problem, whether it is solid wood or composite floor now installed under the floor is used in the material, do not believe you can ask it to. Laying on the ground, a damp proof and moisture-proof, protect the floor, increase the elasticity of the film, the ideal thickness is more than 0.22mm, and has the properties of alkali resistant, acid resistant

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Decking Wpc Outdoor with SGS and CE from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords