D811ERoad Roller Buy D811H Road Roller at Okorder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: D811E Road Roller

Parameter:

| Type | Unit | D811E |

| Operating weight (including cab) | kg | 11300 |

| load on front drum | kg | 5650 |

| Load on rear wheels | kg | 5650 |

| Static linear load | N/cm | 298/298 |

| Speed | km/h | 0—10 |

| Gradeability in theory | % | 30 |

| Minimum turning radius | mm | 4050/5950 |

| Crab-walking distance | mm | 160 |

| Minimum ground clearance | mm | 340 |

| Wheel base | mm | 3700 |

| Steering angle | ± ° | 35 |

| Swing angle | ±° | 8 |

| Vibration frequency | Hz | 45—48 |

| Nominal amplitude | mm | 0.41/0.8 |

| Centrifugal force | kN | 80/133 |

| Model and manufacturer | DEUTZ BF4M2012C | |

| Rated rotating speed | r/min | 2300 |

| Rated power | kW | 98 |

| Rated oil wear | g.kw/h | 205 |

| Water tank capacity | L | 2×450 |

| Fuel tank capacity | L | 210 |

Advantages:

state-owned company

fortune 500 company

AAcustom

Why choose us?

1 sincre

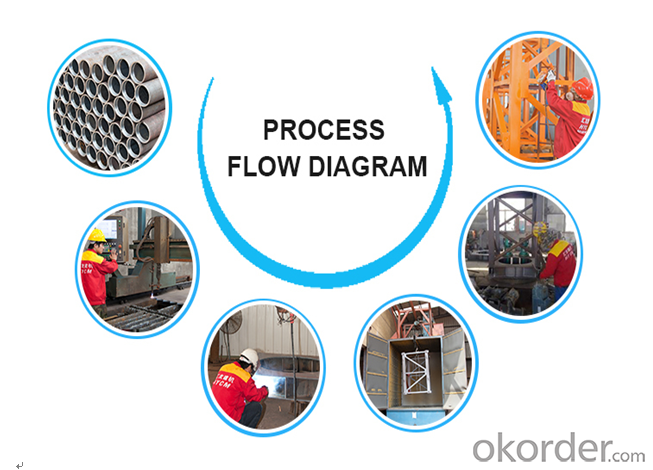

CNBM International is a state company, now is one of the largest state-owned group cooperation in China! All the equipment such as tower cranes, produced by CNBM are compliant with the national level quality.

2 professional

Our engineers will at your services 24hours to solve all your tower crane installation and other questions. Our goal is to provide the best professional services.

3 quality

CNBM International’s tower crane have strict quality control, only the best quality products can pass the test.

4speed

We have professional sales team to guarantee your reply within 12hours to save your precious time.

5 After sales

If the tower crane has any problems, we will solve your problems in first time.

Inquies FAQ

My dearest friend, if you want to buy our tower cranes, please tell us the following parameters. And we will make the most suitable project for!

1. Building height or tower crane working height.

2. Max load capacity and tip load capacity.

3. Span or jib length

4. Other Special requirements

- Q:Why should we use the rubber tyred roller in the construction of the asphalt pavement?

- At present, the latter two are widely used in construction.The following is a steel wheel roller, which is in front of the paver. The following table shows two rubber tyred rollers. Roller's purpose: 1. to achieve the required density (usually controlled by compaction); 2. press out the smooth surface.General compaction includes initial pressure, re pressure and final pressure. The final pressure is to remove the traces of rollers, the road is kept smooth, generally can not be omitted, and the use of steel wheel roller. If the initial pressure can meet the density requirements, there is no need to re pressure, but generally still maintain these three steps.

- Q:Do you have a 15T roller?

- Yes, if you are interested, you can go to the building site of the construction machinery to look at it. There are many models and complete data..

- Q:22T vibrating wheel, XCMG, how to refuel?

- Engine oil and hydraulic oil hydraulic system vibration wheel and gear oil rear axle and wheel and gear oil frame with transmission part with butter mouth beat butter (Li Jizhi) brake and clutch brake fluid (brake oil) battery with electrolyte with clean water or glass wiper water tank with clean water or antifreeze professional road machine

- Q:How often do rubber tyred rollers maintain?

- 6 、 check / adjust the clutch pedal height and stroke;7 、 check / adjust the hand brake stroke;8. Check the fastening chassis screws;9. Clean air filter core;10. Add liquid (engine coolant, brake fluid, windshield cleaning fluid, etc.);11. Change engine oil;12. Replace the engine oil filter.

- Q:What kind of vibratory roller is used in roller compacted concrete construction?

- Specific should look at the scale of your project to choose, not a single model of the roller will be able to solve.Hope to be of help to you.

- Q:Then the grass-roots construction to the stability layer, including two ash macadam stage, will use 21T iron three times repeatedly rolling the road. Excuse me, iron three rounds again in this process, the role and vibration roller what is the difference?

- In addition, when you are in the construction of two ash macadam base is best not in windy weather, it will also cause some segregation, the two ash macadam will be very strong, this layer if well, the whole road there is no problem, of course, the premise is to very good foundation, if any the soft soil subgrade subgrade or containing large amount of water and other issues, we must change the fill treatment and so on.I hope I can help you. Give me the reward. I've been in Luqiao for a long time. If you have any problems or projects, I hope we can learn from each other,

- Q:Where are the rollers attached to the rollers?

- There are three. The exact location is as follows:The steel wheel driving speed reducer addition: two is 90 degrees, and put the oil nut, screw it loose, start the engine running, one oil discharge outlet vertical reducer gear oil released after walking again, the two oil outlet of a vertical and a horizontal from the beginning, at the top of the filler filling gear oil, until the level direction of the oil port gear oil out of date. Refueling capacity of about 4.5L.Vibration wheel gear oil additive: three a 120 degree uniform oil adding and discharging port, oil discharge method ibid, to a vertical oil port down oil, after the oil discharge screw on a rotating steel wheel nut, make an oil outlet straight up, another loose oil the mouth slanting down (because the three port is 120 degrees), from the oil filling port gear oil, until the oil port oblique gear oil out of date. Refueling capacity of about 11.5L.After oil addition: gear reducer bridge observation hole loosen nut central, loosen the direction by the reducer and put the oil nut oil (rear axle oil adding and discharging nut good judgment, nut at the top of a concave circular), and then go nuts loosen upper, middle gear oil to observe the outflow of oil can. Refueling capacity of about 18L.

- Q:Do we have to use rubber wheels? Is there a mandatory rule?The fine-grained AC-13 is ready to let the builders use the rubber wheel, but the builders say the rubber wheel is rarely used. Would I like to know if this is necessary?

- 4, only SMA prohibits the use of rubber wheel rolling, because the rubber wheel will destroy the structure of SMA5, the construction side said that rubber tire is rarely used as an excuse, under normal circumstances, in addition to the use of rubber wheel SMA6, for fine-grained AC-13, if not steel wheels, the problem is not large, if not rubber, certainly not

- Q:When the asphalt surface is rolled, why should the driving wheel of the roller be geared to the paver?

- When paving asphalt surface, rollers usually use steel rollers, steel rollers are compacted without leaving traces (Che Zhe). The driving wheel of the roller is toward the paver, that is, the power wheel faces the asphalt concrete, the material is out of order and the direction is not compacted. In this way, the driving wheel can not form the wave shape because the power is insufficient, and the asphalt concrete is pushed forwards and forwards, so that the smoothness of the surface layer is more easily controlled. At present, most rollers are driven by two wheels.

- Q:It should be the shape of the roller! Ask friends or have other recommended rollers?

- The utility model is suitable for various compacting operations of the static pressure roller by the gravity action of the machine itself, so that the compacted layer is permanently deformed and compacted. It is divided into two types: steel wheel type and tyre type. Grinding wheel grinding, grinding groove structure light and kneading etc.. The most common application of light milling is mainly used for compaction of surface layer of road vibratory roller. With mechanical or hydraulic transmission, the utility model can concentrate the compacted part of the protruding part, and has high compaction and smoothness, and is suitable for the compaction operation of the asphalt pavement. According to the layout of the axle, there are single shaft, single wheel, double shaft, double shaft, three wheel and three axle, three wheel and so on. The internal combustion engine is powered by mechanical or hydraulic transmission. General front wheel steering, good maneuverability, rear wheel drive. In order to improve the steering and rolling performance, the articulated steering structure and all wheel drive should be adopted. The front wheel frame is hinged with the frame to reduce the unusual body sway of the road surface. The rear wheel and the frame are rigidly connected. Hydraulic control, hydraulic cylinder control steering. The front and rear grinding wheels are equipped with scraper to remove the adhesive on the roller.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

D811ERoad Roller Buy D811H Road Roller at Okorder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords