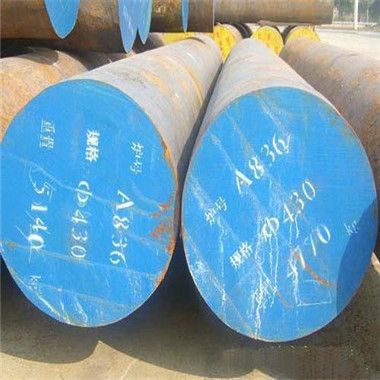

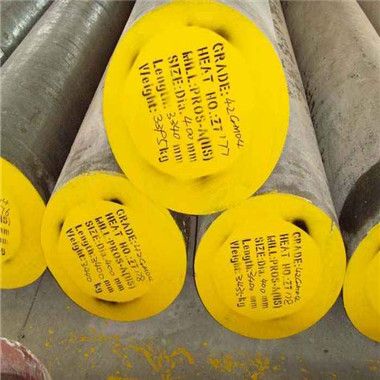

D6 Cold Work Mould Steel Round Bars DIN1.2436

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

D6 Cold Work Mould Steel Round Bars DIN1.2436

AISI D6 tool steel is a high-carbon, high chromium tool steel alloyed with tungsten that is characterized by high compressive strength, high wear resistance, high surface hardness and good hardening stability

Specification of D6 tool steel

1.Diameter:60mm~600mm

2.Length:1-6.5m or as customer's request

The chemical composition of D6 tool steels is outlined in the following table.

| Element | Content (%) |

|---|---|

| Iron, Fe | 83.05 |

| Chromium, Cr | 12.5 |

| Carbon, C | 2.05 |

| Tungsten, W | 1.3 |

| Manganese, Mn | 0.8 |

| Silicon, Si | 0.3 |

Forging

D6 tool steel is heated slowly and uniformly to 700°C (1292°F) and then more rapidly to 900-1050°C (1652-1922°F).

Annealing

D6 tool steel is then annealed at 800-840°C (1472-1544°F) and cooled. Hardness of the steel after annealing will be approximately 225 Brinell.

Stress Relieving

Stresses from D6 tool steel can be eliminated before hardening by heating up to 650-700°C (1202-1292°F), if machining operations have been heavy. The steel is then allowed to cool slowly.

Hardening

D6 steel is pre-heated slowly to 750-800°C (1382-1472°F) and thoroughly soaked. Heating is then continued till the final hardening of 950-980°C (1742-1796°F), followed by air or oil quenching.

Tempering

The steel is heated uniformly and thoroughly at the selected tempering temperature. Double tempering can also be carried out with intermediate cooling to room temperature.

Main applications of D6 tool steels:

Forming tools

Molds for abrasive plastics and ceramics

Long-run press tools

Blanking and shearing tools for hard materials.

- Q:Can steel round bars be used for making automotive chassis?

- Yes, steel round bars can be used for making automotive chassis. Steel round bars offer excellent strength, durability, and load-bearing capabilities, making them suitable for withstanding the weight and stress of an automotive chassis. Additionally, steel's flexibility and malleability allow for customization and shaping to meet specific design requirements.

- Q:How are steel round bars used in the construction of bridges and buildings?

- Steel round bars are widely used in the construction of bridges and buildings due to their strength, durability, and versatility. These bars are typically made of carbon steel and have a circular cross-section, making them perfect for structural applications. In bridge construction, steel round bars are commonly used for reinforcing concrete structures. They are often embedded within concrete beams, columns, and slabs to enhance their load-bearing capacity and resist bending and shearing forces. The bars are placed strategically in the concrete to provide tensile strength, which complements the compressive strength of the concrete. This reinforcement ensures that the bridge can withstand heavy loads and traffic while maintaining its structural integrity. Similarly, in building construction, steel round bars play a crucial role in reinforcing concrete structures. They are commonly used in the construction of columns, beams, and foundations to increase their load-carrying capacity and prevent structural failure. The bars are typically added to the concrete during the pouring process, forming a sturdy framework that enhances the building's strength and stability. Moreover, steel round bars are also used to create steel frames in the construction of buildings. These frames provide the skeletal structure of the building and support the weight of the floors, walls, and roofs. Steel round bars, due to their high strength-to-weight ratio, are ideal for creating lightweight yet robust frames that can withstand various loads, including wind and seismic forces. Additionally, steel round bars are used for other purposes in construction, such as the fabrication of steel reinforcements, connectors, and fasteners. They can be welded, bolted, or threaded to join different structural elements together, ensuring a secure and sturdy construction. Overall, steel round bars are an essential component in the construction of bridges and buildings. They provide the necessary strength, durability, and flexibility required to create structurally sound and long-lasting structures.

- Q:What is the corrosion resistance of steel round bars?

- The corrosion resistance of steel round bars is contingent upon the type of steel used and the environmental conditions to which they are exposed. Generally, stainless steel round bars exhibit outstanding resistance to corrosion due to the inclusion of chromium, which generates a protective layer of oxide on the steel's surface. This oxide layer acts as a barrier, impeding further corrosion. On the other hand, carbon steel round bars are more vulnerable to corrosion, particularly in environments with high levels of moisture or exposure to corrosive substances. In such cases, additional measures such as coatings or galvanizing may be necessary to enhance their resistance to corrosion. It should be noted that the performance of steel round bars in corrosive environments is influenced by various factors, including temperature, pH level, and the presence of other elements or chemicals. Therefore, it is advisable to consider the specific application and seek guidance from corrosion experts in order to determine the most suitable steel grade and corrosion protection measures for your requirements.

- Q:Are steel round bars suitable for the manufacturing of shafts?

- Yes, steel round bars are suitable for the manufacturing of shafts. Steel round bars are known for their strength, durability, and ability to withstand heavy loads and high rotational speeds, making them ideal for shaft applications. The round shape of the bar promotes uniform stress distribution, reducing the risk of failure or deformation. Additionally, steel round bars can be easily machined and heat-treated to achieve desired mechanical properties, such as hardness and toughness, further enhancing their suitability for shaft manufacturing. Overall, steel round bars offer the necessary characteristics required for shafts, making them a reliable and commonly used material in various industries.

- Q:Can steel round bars be anodized?

- No, steel round bars cannot be anodized because anodizing is a process that is specifically designed for aluminum and its alloys. Anodizing involves creating an oxide layer on the surface of the metal, which provides enhanced corrosion resistance and can also be used for decorative purposes. Steel, on the other hand, does not form a stable oxide layer like aluminum, and therefore cannot be anodized in the same way. However, there are other surface treatment options available for steel, such as galvanizing or powder coating, which can provide similar benefits.

- Q:Can steel round bars be used for making bicycle frames?

- Yes, steel round bars can be used for making bicycle frames. Steel is a popular material choice for bicycle frames due to its strength, durability, and ability to absorb vibrations. Steel round bars can be easily shaped and welded to create a sturdy and reliable frame for bicycles.

- Q:What are the advantages of using mild steel round bars?

- There are several advantages of using mild steel round bars in various applications. Firstly, mild steel round bars have excellent strength and durability. They are able to withstand high amounts of stress and pressure, making them suitable for use in construction, manufacturing, and engineering projects. The strength of mild steel round bars ensures that they do not easily deform or break under heavy loads, providing a reliable and long-lasting solution. Secondly, mild steel round bars have good weldability. They can be easily joined or attached to other materials through welding, making them versatile in different applications. This allows for easy customization and flexibility in design, as the bars can be shaped and connected to create complex structures or components. Additionally, mild steel round bars have a low carbon content, making them more cost-effective compared to other types of steel. They are readily available and affordable, making them a popular choice in various industries. Moreover, mild steel round bars have good machinability. They can be easily cut, drilled, and shaped using common machining techniques, allowing for easy fabrication and customization. This makes them suitable for a wide range of applications, from construction to automotive components. Lastly, mild steel round bars have good corrosion resistance. While they may not be as corrosion-resistant as stainless steel, they still offer adequate protection against rust and other forms of corrosion. This makes them suitable for outdoor applications or environments with high humidity or exposure to moisture. In summary, the advantages of using mild steel round bars include their excellent strength and durability, good weldability, cost-effectiveness, machinability, and corrosion resistance. These factors make them a reliable and versatile choice for various industrial and construction applications.

- Q:How to make the round welds on flat steel flat and qualified?

- It is required that the current is suitable and the bar is stable. If required, the groove can be turned on the round steel to ensure that the welding is beautiful and qualified

- Q:What is the modulus of elasticity of a steel round bar?

- The modulus of elasticity of a steel round bar, also known as Young's modulus, is a measure of its stiffness and ability to withstand deformation when subjected to an applied force. The modulus of elasticity for steel is typically around 200 GPa (Gigapascals). This means that for every unit of stress applied to the steel round bar, it will undergo an elastic deformation of approximately 0.0035-0.005, depending on the specific grade and composition of the steel. The modulus of elasticity is an important property to consider in structural and mechanical engineering applications, as it determines the amount of deflection or deformation that can be expected under different loading conditions.

- Q:Are steel round bars resistant to chemicals or acids?

- Most chemicals and acids do not affect steel round bars, although the level of resistance varies depending on the specific steel type and the concentration and nature of the chemical or acid. Stainless steel round bars, on the other hand, have excellent resistance to corrosion and many types of acids. This makes them ideal for use in industries like chemical processing, food processing, and pharmaceuticals. However, it is worth noting that aggressive chemicals and acids, such as hydrochloric acid or sulfuric acid at high concentrations, can still cause corrosion or damage to steel round bars. In these instances, it is advisable to seek advice from experts or consult material compatibility charts to determine the most appropriate steel alloy for the intended application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

D6 Cold Work Mould Steel Round Bars DIN1.2436

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords