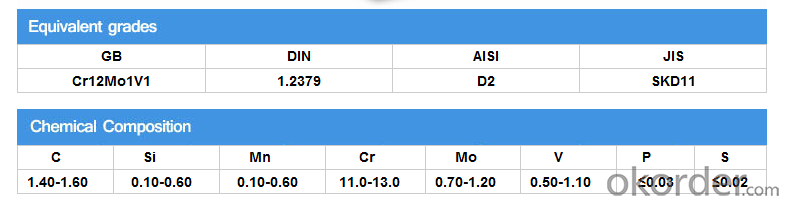

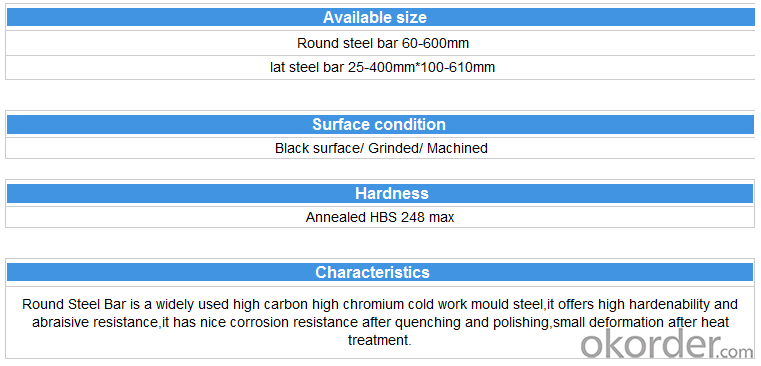

D2 Round Steel Bar,Alloy Steel Round Bars 1.2379,Forged SKD11 Round Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

D2 Round Steel Bar,Alloy Steel Round Bars 1.2379,Forged SKD11 Round Steel Bar

Product information:

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q:What are the different cutting tools used for special steel?

- Some of the different cutting tools used for special steel include high-speed steel (HSS) saw blades, carbide-tipped saw blades, diamond-coated cutting tools, and abrasive wheels. These tools are designed to withstand the hardness and toughness of special steel and provide precise and efficient cutting.

- Q:What are the main factors that affect the machinability of special steel?

- The main factors that affect the machinability of special steel include the steel's chemical composition, microstructure, hardness, and the presence of impurities or non-metallic inclusions. Additionally, factors such as cutting tool material, cutting speed, feed rate, and coolant usage also influence machinability.

- Q:How does special steel perform in extreme heat conditions?

- Special steel performs exceptionally well in extreme heat conditions. It has excellent heat resistance properties, enabling it to maintain its strength and structural integrity even at high temperatures. This makes it highly suitable for applications that involve exposure to extreme heat, such as in industrial furnaces, jet engines, and power plants. Its ability to resist thermal deformation and retain its mechanical properties ensures optimal performance and safety in such demanding environments.

- Q:How does sulfur affect the machinability of special steel?

- Sulfur can have both positive and negative effects on the machinability of special steel. On one hand, sulfur acts as a free-machining element when added in small amounts. It forms sulfide inclusions that help improve the chip-breaking ability during machining, resulting in better surface finish, reduced tool wear, and improved cutting speeds. This is particularly beneficial for high-speed machining operations. On the other hand, excessive sulfur content can have detrimental effects on machinability. High levels of sulfur can lead to the formation of brittle sulfide inclusions, causing poor machinability and reduced mechanical properties. It can result in increased tool wear, poor surface finish, and lower cutting speeds. Additionally, sulfur can promote the formation of built-up edge, which further hampers the machinability of special steel. Therefore, it is crucial to maintain an optimal sulfur content in special steel to strike a balance between improved machinability and maintaining the desired mechanical properties. Proper control of sulfur levels in the steel composition, along with appropriate machining techniques and tool selection, is necessary to achieve efficient and high-quality machining of special steel.

- Q:What are the properties of electrical resistance steel?

- Electrical resistance steel, also known as resistivity steel, possesses specific properties that make it suitable for various electrical applications. This type of steel has a high resistivity, meaning it resists the flow of electrical current more than other materials. It also exhibits low electrical conductivity, making it an ideal choice for applications that require insulation or the control of electrical current. Additionally, electrical resistance steel typically has good mechanical strength, corrosion resistance, and can withstand high temperatures, making it suitable for use in electrical resistors, heating elements, and other similar devices.

- Q:What are the main characteristics of electrical steel?

- Electrical steel, also known as silicon steel or transformer steel, possesses several main characteristics that make it suitable for use in electrical appliances and power equipment. Firstly, electrical steel has a high magnetic permeability, which means it can easily conduct magnetic flux. This property allows it to efficiently transfer electrical energy and reduce energy losses in transformers, motors, and generators. Secondly, electrical steel exhibits low core loss, also known as hysteresis loss and eddy current loss. Hysteresis loss refers to the energy dissipated due to the reversal of magnetic domains within the material, while eddy current loss is caused by circulating currents induced by alternating magnetic fields. The low core loss property of electrical steel enables high energy efficiency and minimizes heat generation in electrical devices. Another important characteristic of electrical steel is its high electrical resistivity. This property reduces the magnitude of eddy currents, further reducing energy losses in electrical equipment. Additionally, electrical steel has a high saturation induction, which refers to its ability to reach maximum magnetic flux density. This characteristic allows transformers and motors to operate at higher magnetic flux densities, resulting in more compact and efficient designs. Furthermore, electrical steel possesses a high mechanical strength, which is crucial for withstanding the stresses and vibrations encountered in electrical devices. It also exhibits good thermal conductivity, enabling efficient heat dissipation and enhancing the overall performance and longevity of electrical equipment. In summary, the main characteristics of electrical steel include high magnetic permeability, low core loss, high electrical resistivity, high saturation induction, high mechanical strength, and good thermal conductivity. These properties make it an ideal material for various electrical applications, providing efficiency, reliability, and performance in power generation, transmission, and utilization.

- Q:How does special steel compare to other materials like aluminum or titanium?

- Special steel, such as stainless steel or tool steel, offers several advantages over materials like aluminum or titanium. Firstly, special steel generally exhibits higher strength and hardness, making it ideal for applications requiring durability and resistance to wear. Secondly, special steel possesses excellent thermal conductivity, allowing it to dissipate heat more efficiently compared to aluminum or titanium. Additionally, special steel is often more cost-effective and readily available in comparison to titanium. However, aluminum and titanium are known for their lightweight properties, making them preferable for applications where weight reduction is crucial. Ultimately, the choice between special steel, aluminum, or titanium depends on the specific requirements and constraints of the intended application.

- Q:What are the applications of special steel in the power generation supply chain?

- Special steel has various applications in the power generation supply chain, primarily due to its high strength, corrosion resistance, and ability to withstand extreme temperatures. It is commonly used in the construction of power plant components such as turbines, boilers, and heat exchangers. Special steel is also utilized in the manufacturing of transmission towers, electrical transformers, and generator rotor shafts. Overall, its superior properties enhance the efficiency, reliability, and longevity of power generation equipment, ensuring a stable and uninterrupted energy supply.

- Q:What are the properties and characteristics of special steel?

- Special steel, also known as alloy steel, has several unique properties and characteristics. Firstly, it possesses exceptional strength, making it highly resistant to deformation and wear. This strength is often achieved through the addition of various elements such as chromium, nickel, and molybdenum, which enhance its toughness and hardness. Additionally, special steel exhibits excellent corrosion resistance, allowing it to withstand harsh environments without succumbing to rust or degradation. It also demonstrates good heat resistance, making it suitable for applications involving high temperatures. Moreover, special steel can be easily machined and welded, offering versatility in manufacturing processes. Overall, the properties and characteristics of special steel make it a preferred material for a wide range of industries, including aerospace, automotive, and construction.

- Q:Can special steel be used for making power generation equipment?

- Yes, special steel can be used for making power generation equipment. Special steel is known for its high strength, durability, and resistance to corrosion, making it an ideal choice for manufacturing components such as turbines, generators, and boilers that are used in power generation processes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

D2 Round Steel Bar,Alloy Steel Round Bars 1.2379,Forged SKD11 Round Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords