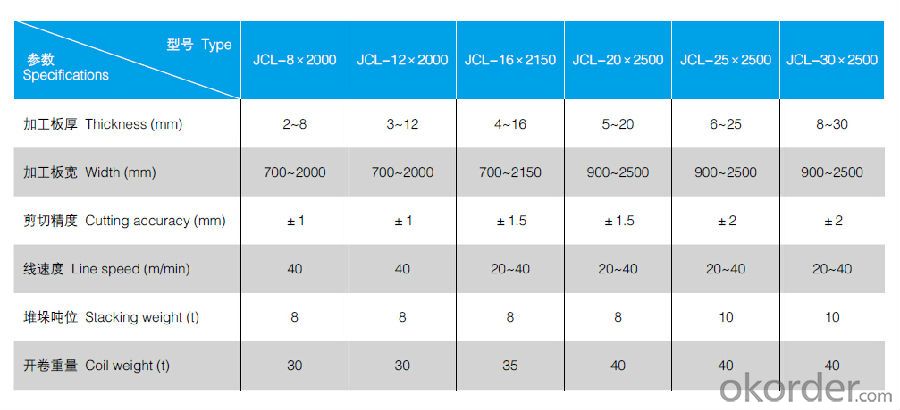

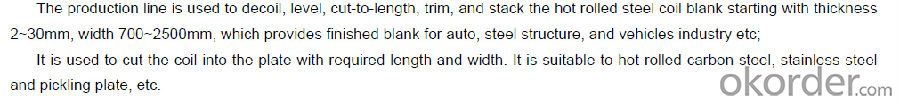

Cut-to-length Line for Hot Rolled Steel(Medium and Thick Plate)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:What is the spark?

- Some materials under the action of mechanical stress, resulting in the internal positive and negative charge center relative displacement and polarization, resulting in the surface of the material at both ends of the symbol of the opposite charge of the charge phenomenon, known as the piezoelectric effect. With this performance of the ceramic into the pressure

- Q:EDM machine working fluid which

- EDM EDM: 1. Wire cutting in the processing industry is mainly deionized wate

- Q:Wire cutting processing thickness of how to adjust the parameters

- By the discharge processing erosion conditions constraints, to a certain extent, processing is very unstable, until there is no current discharge short circuit occurs.

- Q:Why does EDM work?

- High temperature makes the surface of the workpiece melting, gasification and explosive splashing into the processing fluid, quickly solidified into discharge slag, the working fluid was taken away. X0d At this time on the surface of the workpiece will leave a tiny pits,

- Q:With the increase in wire speed, in a certain range, the processing speed will increase.

- Usually wire EDM wire electrode material should have good conductivity, electronic spillage should be small, high tensile strength, good resistance to electrical corrosion.

- Q:What is the electric discharge machine?

- EDM is the use of immersion in the working fluid between the two electrodes between the pulse discharge caused by the erosion of the conductive material of the special processing methods, also known as discharge processing or electro-erosion processing, the English referred to as EDM.

- Q:What is the wire cutting EDM machine?

- 1. To provide more than 20,000 sets of file storage (mainly determined by the size of the internal hard drive), can be stored in accordance with the different mold or customer number twenty thousand processing coordinates Xing processing conditions, so with a number of processing coordinates memory function, and has

- Q:Evaluation of EDM wire cutting process effect is good or bad, generally used to measure what

- Workpiece processing accuracy, resulting in poor quality; its three ﹑ on the operator's safety and physical health are also harmful.

- Q:Perforating machine | EDM punching machine | small hole machine 0.1-0.3mm | ultra-fine hole EDM machine |

- Punching Machine | EDM Punching Machine | Pore EDM | Ultra High Speed Pore EDM Machine (0.15 ~ 3.0mm Punching Machine) Model: H3

- Q:How to quickly control the Mitsubishi wire cutting machine

- In the past, the laser cutting machine was considered to be suitable for a variety of small-scale production, but the laser processing machine did not require the traditional mold, the processing quality is high, and at this point is superior to the punch, the high-speed cutting performance is improved

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cut-to-length Line for Hot Rolled Steel(Medium and Thick Plate)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords