Customized Aluminum Profile for Closet Door

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Customized Aluminum Profile for Closet Door Description:

Customized Aluminum Profile for Closet Door (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Customized Aluminum Profile for Closet Door:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

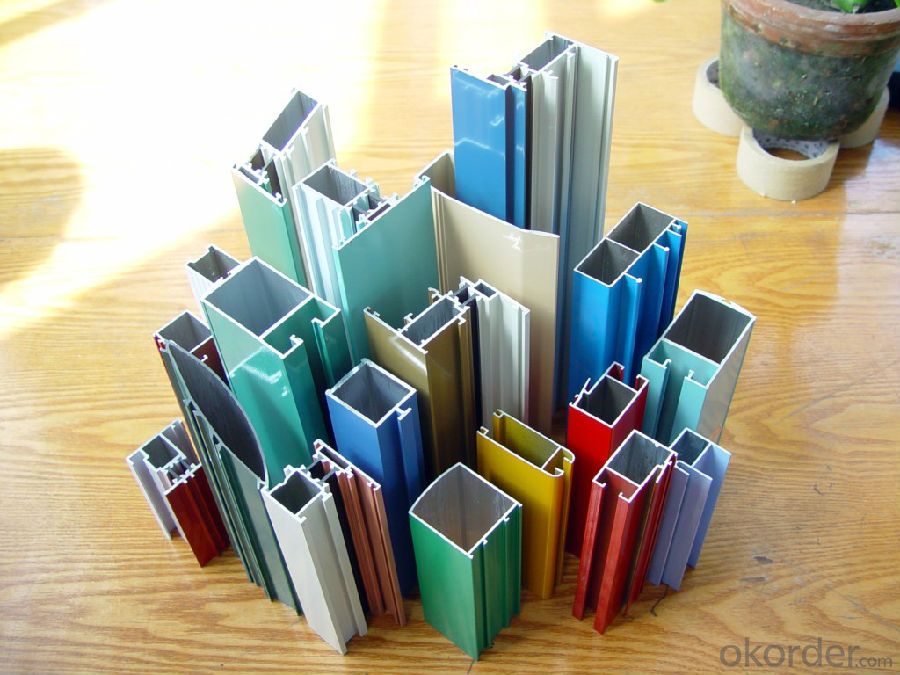

3.Customized Aluminum Profile for Closet Door Images:

4.Customized Aluminum Profile for Closet Door Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:could you please help me find information of the element aluminum??? all the information i can get will be great... thanks very mucho.... who discovered? where can i find pictures of it?

- Aluminum is from team 3 and there for has 3 electrons in its outer shell and desires 5 to fill it. it rather is going to react with any factors from team 5 that want aluminum's 3 electrons.

- Q:Can aluminum coils be used for industrial piping?

- Yes, aluminum coils can be used for industrial piping. Aluminum is a versatile and lightweight material that offers several advantages for industrial piping applications. It has excellent corrosion resistance, which makes it suitable for various industries, including chemical, petrochemical, and food processing. Aluminum coils are also easy to work with and can be formed into different shapes and sizes, allowing for flexibility in designing and installing piping systems. Additionally, aluminum has good thermal conductivity, which is beneficial for applications that require heat transfer. However, it is important to consider the specific requirements of the industrial process and consult with experts to ensure that aluminum coils are suitable for the intended application.

- Q:What is the impact resistance of aluminum coils?

- The impact resistance of aluminum coils is generally high. Aluminum has a good strength-to-weight ratio and is known for its ability to withstand impact and deformation without breaking or fracturing easily. This makes aluminum coils suitable for various applications where resistance to impacts and mechanical stress is important, such as in construction, automotive, and aerospace industries.

- Q:What are the different color options for anodized aluminum coils?

- An extensive array of color choices is available when it comes to anodized aluminum coils. To create a protective oxide layer on the surface, the aluminum is immersed in an electrolyte solution and an electric current is applied during the anodization process. This oxide layer can be dyed in various colors, providing customization and aesthetic improvement. Anodized aluminum coils come in popular colors such as silver, black, bronze, gold, copper, and champagne. These colors are achieved by using different dye solutions during the anodization process. Moreover, each color category offers a variety of shades and finishes, giving more versatility and options. The color possibilities for anodized aluminum coils are not limited to solid colors alone. By employing masking techniques or advanced printing technologies, it is also possible to create patterns, gradients, and even custom designs. This grants even more freedom for creativity and the ability to match specific branding or design requirements. What's more, anodized aluminum coils possess excellent color retention and durability. The anodized oxide layer not only shields against corrosion and wear but also acts as a foundation for the dyed color, resulting in long-lasting and vibrant finishes. To summarize, the range of color options for anodized aluminum coils is vast and varied, encompassing traditional metallic finishes as well as bold and unique shades. This assortment ensures limitless possibilities in architectural, industrial, and decorative applications, guaranteeing a suitable color option for any project.

- Q:Can aluminum coils be used for food storage containers?

- Yes, aluminum coils can be used for food storage containers. Aluminum is a safe and commonly used material for food packaging due to its non-toxic, lightweight, and corrosion-resistant properties. It helps to preserve the freshness, flavor, and quality of food while also being recyclable and environmentally friendly.

- Q:Are aluminum coils suitable for reflective insulation?

- Yes, aluminum coils are suitable for reflective insulation. Aluminum is a highly reflective material that can effectively reflect heat and light, making it an excellent choice for insulation applications that require thermal control and energy efficiency.

- Q:What is the maximum coil weight for aluminum coils?

- The maximum weight of aluminum coils can differ due to several factors including coil thickness, width, and the specific alloy employed. Typically, the maximum weight for aluminum coils falls within the range of 5,000 to 25,000 pounds. Nevertheless, it is crucial to acknowledge that these figures are only approximate and may vary based on the manufacturer's guidelines and the capabilities of the equipment. Moreover, it is advisable to consult the manufacturer or supplier in order to ascertain the specific limitations on coil weight to guarantee safe handling and transportation.

- Q:Are there any limitations to the maximum coil length of aluminum coils?

- Yes, there are limitations to the maximum coil length of aluminum coils. The length of aluminum coils is typically restricted by factors such as the capabilities of manufacturing equipment, transportation constraints, and handling limitations. Additionally, longer coils are more prone to issues like coil sagging and deformation during storage or handling. Therefore, there is a practical limit to the maximum coil length that can be produced and effectively utilized in various industries.

- Q:You guys may be thinking, why the hell i posted this in the computer section. Well, I'm opening my computer, and I hate the anti-static wristbands. I know that by touching metal, you can get rid of all static electricity in your hands. Can you do this by touching aluminum foil? Since it's something everyone should have in their house.. Can it work like this?

- Static shield is fine. But for relatively unhealthy hair static, I use material softener sheets. Just rub over your hair. You too can rub the within of your coat with the dryer sheet, not more static. Keep one in a ziploc baggie to your coat pocket, it is going to final fairly a even as. Bonus, you scent like contemporary laundry :) Better than smelly Static Guard.

- Q:How are aluminum coils used in the production of electronic devices?

- Aluminum coils are used in the production of electronic devices for various purposes such as providing electrical conductivity, heat dissipation, and electromagnetic shielding. These coils are typically used in components like transformers, inductors, and motors, where they help in the efficient transfer of electrical energy. Additionally, aluminum coils are often employed in cooling systems to dissipate heat generated by electronic components, ensuring their optimal performance and preventing overheating. Furthermore, aluminum coils can be utilized to create electromagnetic shields that protect sensitive electronic circuits from external electromagnetic interference, thus enhancing the overall reliability and functionality of electronic devices.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Customized Aluminum Profile for Closet Door

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords