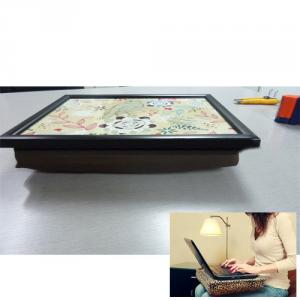

Cushion Lap Tray Hot Selling

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Sets pc

- Supply Capability:

- 600,000 Set/Sets per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.ASTM A106/A53 GR.B

2.Outer diameter:10.3-194.4mm

3.Wall thickness:6.5-59mm

4.Cer:ISO9001:2008,API

Seamless steel pipe

(1) Standard: GB8163, ASTM A106/A53/API 5L

(2) Material: 10#, 20#, 16Mn, A106Gr.A/B/C,

(3)Specification: O.D: 21.3mm-711.2 mm

(4) W.T: 2.11mm-59.54mm

Technical Parameters of Seamless Steel Pipe

A53: Chemical components and mechanical property

Stan- dard | Trade mark | Chemical components | Mechanical property | ||||||||||

| C | Si | Mn | P,S | Cu | Ni | Mo | Cr | V | Tensile Strength | Yield Strength | Elongation | ||

ASTM A53 | A | ≤0.25 | / | ≤0.92 | ≤0.05 | ≤0.06 | ≤0.40 | ≤0.15 | ≤0.40 | ≤0.08 | ≥330 | ≥205 | ≥29.5 |

| B | ≤0.30 | / | ≤1.2 | ≤0.05 | ≤0.06 | ≤0.40 | ≤0.15 | ≤0.40 | ≤0.08 | ≥415 | ≥240 | ≥29.5 | |

A106: Chemical components and mechanical property

| Stan-dard | Trade mark | Chemical components | Mechanical property | ||||||||||

| C | Si | Mn | P,S | Cu | Ni | Mo | Cr | V | Tensile Strength | Yield Strength | Elongation | ||

ASTM A106 | B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.40 | ≤0.08 | ≥415 | ≥240 | ≥30 |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.40 | ≤0.08 | ≥485 | ≥275 | ≥30 | |

PSL 1: Chemical components and mechanical property

| Class and Sort | Chemical components | Mechanical property | |||||||

| C(Max) | Mn(Max) | P(Max) | S(Max) | Tensile Strength(Min) | Yield Strength(Min) | ||||

| A25 | CL I | 0.21 | 0.60 | 0.030 | 0.030 | 45.000 | 310 | 25.000 | 172 |

| CL II | 0.21 | 0.60 | 0.030 | 0.030 | |||||

| A | 0.22 | 0.90 | 0.030 | 0.030 | 48.000 | 331 | 30.000 | 207 | |

| B | 0.28 | 1.20 | 0.030 | 0.030 | 60.000 | 414 | 35.000 | 241 | |

| X42 | 0.28 | 1.30 | 0.030 | 0.030 | 60.000 | 414 | 42.000 | 290 | |

| X46 | 0.28 | 1.40 | 0.030 | 0.030 | 63.000 | 434 | 46.000 | 317 | |

| X52 | 0.28 | 1.40 | 0.030 | 0.030 | 66.000 | 455 | 52.000 | 359 | |

| X56 | 0.28 | 1.40 | 0.030 | 0.030 | 71.000 | 490 | 56.000 | 386 | |

| X60 | 0.28 | 1.40 | 0.030 | 0.030 | 75.000 | 517 | 60.000 | 414 | |

| X65 | 0.28 | 1.40 | 0.030 | 0.030 | 77.000 | 531 | 65.000 | 448 | |

| X70 | 0.28 | 1.40 | 0.030 | 0.030 | 82.000 | 565 | 70.000 | 483 | |

Our catalog of Seamless steel pipe

| item | material | standard | specification (OD*WT)mm | usage |

| alloy pipe | Cr5Mo. 15CrMo 13CrMo44 12Cr1MoV P22 T91,P91,P9, T9 Wb36 | GB5310-95 GB9948-88 ASTMA335/A335M ASTMA213/213M DIN17175-79 JISG3467-88 JISG3458-88 | 16-824*2-100 | The seamless steal pipes features resistance to high pressure, high/low temperature and corrosion and is used in the industries of petroleum, chemical engineering and. Electric power as well as boiler |

High-pressure boiler pipe | 20G,A106, ST 45 | GB5310-95 ASTM A 106-99 DIN17175-79 | 14-630*2-80 | Temperature-resistant seamless steel pipe far high-pressure boiler |

Seamless pipes for petroleum | 20, 12CrMo, 15CrMo | GB9948-88 | 10-530*1.5-36 | Boiler pipes for refinery, heat-exchanging pipes, seamless steel pipes for pipeline |

High-pressure Seamless pipes for fertilizer making equipment | 20, 16Mn, Q345 | GB6479-2000 | 18-530*3-40 | Fertilizer making equipment and pipe line |

Low and medium- pressure boiled pipe | 10,20 | GB3087-1999 | 10-530*2-40 | Over-heat pipe for low and medium pressure boiler, boiling water pipe, locomotive smoke pipe(big and small) |

| Fluid pipe | 20, Q345 | GB/T8163-1999 | 8-630*1.0-40 | Fluid feeding |

| Structural pipe | 20, Q345 10, 20,35,45, 16Mn,Q345B | GB/T8162-1999 | 6-1020*1.5-100 | For common structure |

| Line pipe | Gr.B | API | 60-630*1.5-40 | Carrying gas, water or oil in the industries of petroleum and natural gas |

Hydraulic prop pipe | 27SiMn | GB/T17396-1998 | 70-377*9-40 | Hydraulic support and prop |

- Q:Can steel pipes be used for stormwater management systems?

- Yes, steel pipes can be used for stormwater management systems. Steel pipes are a commonly used material for stormwater management due to their durability, strength, and resistance to corrosion. They can effectively carry and transport stormwater, making them suitable for various applications in stormwater management systems.

- Q:Can steel pipes be used for underground cooling systems?

- Yes, steel pipes can be used for underground cooling systems. Steel pipes are commonly used in various applications, including underground cooling systems, due to their durability, strength, and resistance to corrosion. They can effectively handle the high pressure and temperature demands of cooling systems. Additionally, steel pipes can be welded or threaded together, allowing for easy installation and maintenance. However, it is important to ensure that the steel pipes are properly coated or insulated to prevent corrosion and maintain efficiency in heat transfer.

- Q:How are steel pipes used in the manufacturing of pharmaceutical equipment?

- Steel pipes are commonly used in the manufacturing of pharmaceutical equipment for various purposes such as transferring fluids, gases, and chemicals, as well as providing structural support to the equipment. These pipes are known for their durability, corrosion resistance, and ability to withstand high pressure, making them ideal for ensuring the safe and efficient operation of pharmaceutical machinery.

- Q:What are the different methods of joining steel pipes for high-pressure applications?

- The different methods of joining steel pipes for high-pressure applications include welding, threaded connections, flanged connections, and grooved connections. Welding involves fusing the ends of the pipes together using heat, creating a strong and leak-proof joint. Threaded connections involve screwing the pipes together, using threads on the ends of the pipes and pipe fittings. Flanged connections involve using flanges, which are flat, circular discs with bolt holes, to connect the pipes together. Grooved connections involve using grooved couplings that grip the ends of the pipes and are secured with bolts, creating a reliable and easy-to-install joint.

- Q:Can steel pipes be used in plumbing systems?

- Yes, steel pipes can be used in plumbing systems. Steel pipes have been traditionally used in plumbing systems for their durability, strength, and resistance to corrosion. However, other materials like copper and plastic pipes have become more popular in recent years due to their ease of installation, lower cost, and better resistance to certain types of corrosion.

- Q:How are steel pipes used in the power generation sector?

- Steel pipes are commonly used in the power generation sector for various applications such as transporting water, steam, and other fluids within power plants. They are used for conveying high-pressure steam to drive turbines and generate electricity, as well as for transporting cooling water to regulate temperature in power plants. Additionally, steel pipes are used in the construction of power plant infrastructure, including the fabrication of boiler tubes, condenser tubes, and other critical components that ensure efficient and reliable power generation.

- Q:Can steel pipes be used for conveying slurry?

- Yes, steel pipes can be used for conveying slurry. Steel pipes are widely used in various industries for transporting different types of fluids, including slurry. Slurry is a mixture of solid particles suspended in a liquid, and steel pipes are well-suited for handling such mixtures due to their strength, durability, and resistance to corrosion. Steel pipes are also known for their high-pressure and high-temperature capabilities, making them suitable for conveying slurry in demanding applications such as mining, dredging, and wastewater treatment. Additionally, steel pipes can be easily welded, allowing for the construction of long pipelines that can efficiently transport slurry over long distances. However, it is important to consider the specific characteristics of the slurry being conveyed, such as particle size, density, and abrasiveness, to ensure proper pipe selection and design for optimal performance and longevity.

- Q:What is the role of steel pipes in power plants?

- Steel pipes play a crucial role in power plants as they are used for transporting various fluids, such as water, steam, and fuel, throughout the facility. These pipes are designed to withstand high temperatures, pressure, and corrosive environments, ensuring a safe and efficient operation of power generation equipment. They facilitate the circulation of cooling water, carry steam to drive turbines, and transport fuel to boilers, helping to generate electricity in power plants.

- Q:How do steel pipes compare to other pipe materials like PVC or copper?

- Steel pipes have several advantages over other pipe materials like PVC or copper. Firstly, steel pipes are incredibly strong and durable, making them suitable for high-pressure applications and long-term use. They have a higher resistance to cracking or breaking, which is especially beneficial in demanding environments. Secondly, steel pipes have excellent heat resistance, making them ideal for transporting hot fluids. On the other hand, PVC pipes are more lightweight, cost-effective, and easy to install, making them suitable for non-pressure applications. Copper pipes are known for their corrosion resistance and ability to handle high temperatures, but they are typically more expensive. Overall, the choice between steel, PVC, or copper pipes depends on the specific requirements of the application, considering factors like pressure, temperature, cost, and ease of installation.

- Q:What are the different methods of pipe inspection for steel pipes?

- There are several methods of pipe inspection that can be used for steel pipes. Some of the commonly used methods are as follows: 1. Visual Inspection: This is the most basic form of pipe inspection where a trained inspector visually examines the exterior and interior of the pipe to identify any visible defects or abnormalities. This method is often used as a preliminary inspection before more advanced techniques are employed. 2. Magnetic Particle Inspection (MPI): MPI involves applying a magnetic field to the steel pipe and then applying iron particles to the surface. Any surface cracks or defects in the pipe will cause a leakage of magnetic flux, which can be detected by the inspector. This method is particularly effective in identifying surface defects in ferromagnetic materials. 3. Ultrasonic Testing (UT): UT is a non-destructive testing method that uses high-frequency sound waves to detect internal defects or anomalies in steel pipes. A transducer is used to send ultrasonic waves into the pipe, and the reflections or echoes of the sound waves are analyzed to determine the presence of defects such as corrosion, cracks, or wall thickness variations. 4. Radiographic Testing (RT): In this method, X-rays or gamma rays are used to create an image of the internal structure of the steel pipe. The X-rays or gamma rays pass through the pipe, and the resulting image can reveal any defects, such as cracks, corrosion, or weld discontinuities. This method is commonly used for inspecting welded joints. 5. Eddy Current Testing (ECT): ECT is a non-destructive testing technique that uses electromagnetic induction to detect surface and near-surface defects in steel pipes. A coil carrying an alternating current is passed over the pipe's surface, and any changes in the electrical conductivity or magnetic field caused by defects are detected and analyzed. 6. Acoustic Emission Testing (AET): AET is a method that detects and analyzes the high-frequency acoustic signals emitted by materials when they undergo deformation or damage. In the case of steel pipes, AET can be used to monitor and identify defects such as cracks, leaks, or corrosion by analyzing the acoustic signals emitted during service or under stress. These are just a few of the commonly used methods of pipe inspection for steel pipes. The choice of method depends on various factors such as the type of defect being looked for, the accessibility of the pipe, the desired level of sensitivity, and the cost and time constraints. It is often recommended to use a combination of inspection techniques to ensure a thorough assessment of the steel pipes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

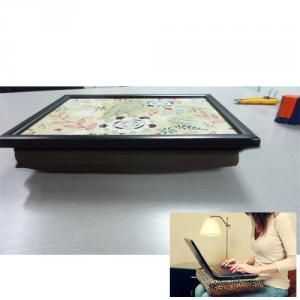

Cushion Lap Tray Hot Selling

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Sets pc

- Supply Capability:

- 600,000 Set/Sets per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords