Cuplock System OEM Service/High Quality Scaffolding CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Cuplock System OEM Service/High Quality Scaffolding

Type: Heavy Section Steel

Forming: Welding Products

Standard:

Member:

Trademark:

Connection Form:

Carbon Structural Steel:

Residential Wall Structure:

Type of Steel For Building Structure:

Bs1139, En74 Standard:

Export Markets:

Descriptions of Cuplock System OEM Service/High Quality Scaffolding

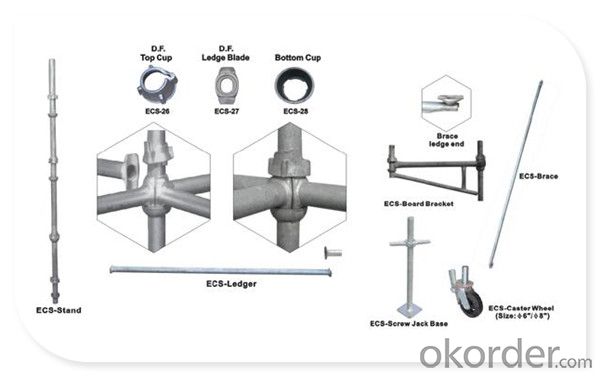

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Cuplock System OEM Service/High Quality Scaffolding

Multi-functional-with the universal joint and fully interchangeable components, the cuplock system can be used in most construction projects for both formwork and access. It is very versatile and diverse. Use in the shipping industries, oil and gas and aviation industries.

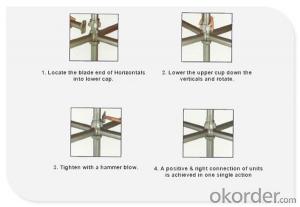

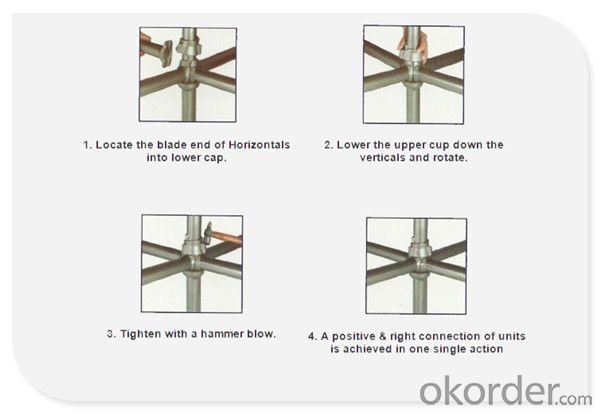

Versatile-Verticals are assembled with horizontals and diagonals using secure fixed cup connections. Its versatility has a distinct advantage to conventional scaffolding methods. A positive & ridged connection of four units is achieved in one single action. The cupock system is very cost effective and can be erected safely and quickly.

Time saving-cuplock scaffold is the solution for temporary structures Performance stages. Small teams can erect it safely and quickly.

Economical-Easily assembled system scaffold saves time and labor costs.

Durable-All components are hot dip galvanized and manufactures to international standard.

Easily Stored-Individual pipe elements can be packed in bundles for easy storage and transportation. For returns, material can be packed in steel racks.

The Main Components of Cuplock System OEM Service/High Quality Scaffolding

Verticals

Description

Material

kg/pc

Article No.

9'10" Vertical 3.00m

Q345 φ48.3×3.2

16.90

SC1001 3000

8'2" Vertical 2.50m

Q345 φ48.3×3.2

14.20

SC1001 2500

6'6" Vertical 2.00m

Q345 φ48.3×3.2

11.60

SC1001 2000

4'11" Vertical 1.50m

Q345 φ48.3×3.2

8.90

SC1001 1500

3'3" Vertical 1.00m

Q345 φ48.3×3.2

6.20

SC1001 1000

1' Vertical 0.50m

Q345 φ48.3×3.2

3.50

SC1001 0500

Horizontals

Description

Material

kg/pc

Article No.

10'0" Horizontal 3.05m

Q345 φ48.3×3.2

11.80

SC1002 3048

9'0" Horizontal 2.74m

Q345 φ48.3×3.2

10.70

SC1002 2743

8'2" Horizontal 2.50m

Q345 φ48.3×3.2

9.80

SC1002 2500

7'0" Horizontal 2.13m

Q345 φ48.3×3.2

8.40

SC1002 2133

6'6" Horizontal 2.00m

Q345 φ48.3×3.2

7.90

SC1002 2000

6'0" Horizontal 1.83m

Q345 φ48.3×3.2

7.20

SC1002 1828

5'11" Horizontal 1.80m

Q345 φ48.3×3.2

7.10

SC1002 1800

5'0" Horizontal 1.52m

Q345 φ48.3×3.2

6.10

SC1002 1524

4'11" Horizontal 1.50m

Q345 φ48.3×3.2

6.00

SC1002 1500

4'1" Horizontal 1.25m

Q345 φ48.3×3.2

5.00

SC1002 1250

4'0" Horizontal 1.22m

Q345 φ48.3×3.2

4.90

SC1002 1219

3'6" Horizontal 1.07m

Q345 φ48.3×3.2

4.30

SC1002 1067

3'3" Horizontal 1.00m

Q345 φ48.3×3.2

4.10

SC1002 1000

3'0" Horizontal 0.91m

Q345 φ48.3×3.2

3.80

SC1002 0914

2'11" Horizontal 0.90m

Q345 φ48.3×3.2

3.70

SC1002 0900

8'0" Horizontal 2.44m

Q345 φ48.3×3.2

9.50

SC1002 2438

1'10" Horizontal 0.57m

Q345 φ48.3×3.2

2.40

SC1002 0600

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:Key points for safety of portal scaffolding

- 2, take off the scaffolding workers must wear a helmet, wearing a seat belt, wear non slip shoes.3, the construction load should meet the design requirements, shall not overload; shall not be stacked on the scaffolding template, steel and other objects. Prohibited in the scaffolding on the pull cable wind rope or fixed, erection of concrete pump, pump and lifting equipment etc..

- Q:Which God can tell me what is required, how to get ah?

- Whether the site is to use their own hand foot disc accessories, accessories or disc scaffolding rental, before use should be carried out preliminary calculation, see how many accessories, the same buildings of different height should be calculated separately, is used to prevent waste of transportation. To achieve cost savings must be accurate calculation. You can go to the mall extension carefully and look at the product deformation, distortion, rust, if any of the above parts, should immediately terminate the use of such products can not be put into construction and.

- Q:Cantilever beam type scaffolding can not exceed the maximum number of not married

- The surface of the board and the bottom of the board should be treated with additional reinforcement.Scaffolding (scaffold) refers to the construction site for the workers to operate and solve the vertical and horizontal transport and erection of various stents. The general term of the construction industry, refers to the construction site used in the external walls, interior decoration or high level can not be directly construction. Mainly in order to work or work on the construction of the perimeter of the safety net enclosure and high altitude installation components, etc., is put on the shelf, scaffolding materials are usually made of bamboo, wood, steel or synthetic materials, etc..

- Q:I am currently taking early childhood care education as my college major. I am learning about ZPD (Zone of Proximal Development), and scaffolding the the development in early childhood.How would you explain, and define scaffolding

- Scaffolding basically means being the support (a scaffold is a support) in the child's learning. A preschooler can do a range of things. He or she will have mastered some things already and there will also be things that are beyond what he or she can do. When playing with the preschooler, you want to make sure that what's going on falls in that range (zone of proximal development). Don't give him or her something that's too easy or too hard to do, but play games that make them think a little and use what he or she already knows to take it a bit further. I hope I'm not confusing you more. In one sentence..scaffolding is supporting the child in learning something new based on what they already can do or know.

- Q:Fastener type steel pipe scaffold composed of which components?

- Reference to "construction safety of steel tubular scaffolding safety technical specifications" JGJ 130 - 2011, 8, page parts3.1 steel pipe3.1.1 scaffolding steel pipe should be used in the current national standard "straight welded steel pipe" GB/T13793 or "low pressure flowQ235 steel pipe for the welded steel pipe used for conveying body; the steel quality of the steel pipe shall be GB/T3091In accordance with the existing national standard "carbon structural steel" GB/T700 Q235 steel provisions.3.1.2 scaffolding steel pipe should be used 48.3 * 3.6. The maximum quality of each steel pipe shall not be greater than25.8kg.

- Q:Im in college football, I would be puting on and taking off my helmet, I usually keep it on though during practice...but would it be wise for me to get an industrial piercing a couple months before 2 a days and the football season...would the sweat maybe infect my ear, but I am a very clean guy? thanks, if you have an answer it will help my decision.....

- trust me, bro. bad idea. industrials are very tempermental at best. your helmet will cause every problem possible. any descent piercer would tell you the same. don't do it. they take up to a year to heal soif you really want one, quit football or wait til you're out of school.

- Q:Erection of scaffolding accessories

- Scaffolding is the door frame, a cross support, connecting rods, hanging button scaffold or horizontal frame, etc. the basic structure of the lock arm, and then set the horizontal reinforcing bar, scissors, sweeping rod, sealing rod, bracket and the base, and the use of a standard wall connecting piece is connected with the main structure of the building standard steel pipe scaffold. Steel pipe scaffold can not only be used as an external scaffold, but also can be used as scaffolding or full scaffolding.

- Q:I know it's soon, but my piercings swollen and quite sore when knocked slightly.I've only had it three or four days, but there's a swollen round lump right next to one pierced hole and I was worried it could be an early sign of a keloid. But I don't know if it's too soon to tell yet.I know they can take up to 6 months to heal, if not more, but I'm kinda paranoid about it.I've rinsed it after showering, used salt water on it every day and apart from that just washed it with water on a cotton bud.Any advice?

- I had my industrial for 13 months and it never healed. I decided to retire it and the piercing sites closed up within 6 hours. Seriously, my advice to you is to just take it out. They are wayyyy more trouble than they are worth.

- Q:In the Scarlet Letter, when Dimmesdale asks Hester who Chillingworth really is, why does she keep her oath to him of not revealing that he is her husband? Guilt? Morals? Thanks

- Because she owes him since she cheated on him.

- Q:i was thinking of having it done. google it if you don't know what it looks like. but i can't handle pain too well, and as i've seen on youtube, its not nice lmfao, i know pain varies from person to person, but any ideas on how to like take your mind off it? im quite young and this is my first major piercing, i only have my lobes done twice;), and does anyone know a good place to find nice barbells once it's healed:)? thanks:)!aaand do you think this is a nice piece to put in once its healed?

- Actually getting it pierced isn't all that painful, it's the couple of weeks after that might hurt...but as long as it's looking after properly (cleaned every day) all should be good. Sleeping on it can be painful, so i would suggest you get the side pierced that you don't usually sleep on. As for taking your mind off it, maybe take someone in with you while you get it done? then you can either talk to them to distract you or just squeeze their hand...also try not to look at the needle as this could just scare you, don't worry too much though, it'll all be over and done with in a few seconds and the pain really isn't that bad. As well as making sure you clean it every day, it's also important to make sure you're not playing with/touching it all the time as this could lead to an infection, always make sure your hands are clean before touching it. That industrial bar looks really nice, i would aim on waiting a couple of months before putting it in though maybe even about 4-5 months. Overall i think you should defiantly get it pierced the look really nice, good luck!! :)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cuplock System OEM Service/High Quality Scaffolding CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords