CS Seamless Steel Pipe ASTM A53/ ASTM A106/ API

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

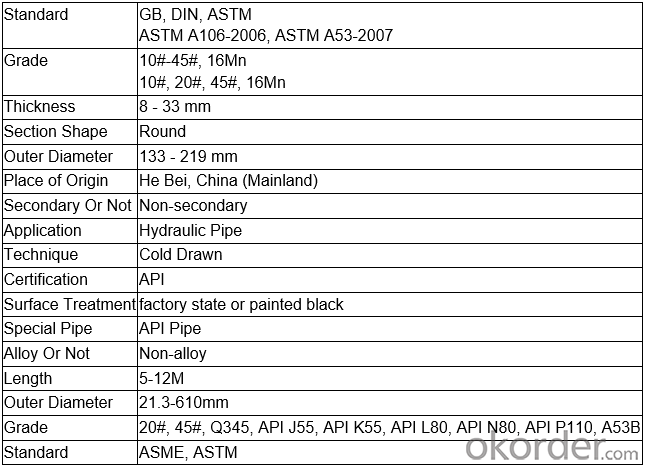

Product Description - CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B:

Structure:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell.

As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable.

Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

Main Features:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

Specifications:

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

- Q:Can steel pipes be used for the construction of offshore platforms?

- Yes, steel pipes can be used for the construction of offshore platforms. Steel pipes are commonly used in offshore platform construction due to their high strength, durability, and resistance to corrosion. These pipes can be used for various purposes such as structural support, transporting fluids, and as conduits for electrical and communication systems. Additionally, steel pipes can be easily fabricated, installed, and maintained, making them a reliable choice for offshore platform construction.

- Q:How do you calculate the stress in a steel pipe?

- To calculate the stress in a steel pipe, you need to determine the applied force or load acting on the pipe and divide it by the cross-sectional area of the pipe. This will give you the stress value, which is typically measured in units of force per unit area (such as pounds per square inch or pascals).

- Q:What is the impact toughness of steel pipes?

- The impact toughness of steel pipes refers to the ability of the material to withstand sudden or high-velocity impacts without fracturing or breaking. It is a measure of the material's resistance to cracking under dynamic loading conditions. The impact toughness of steel pipes is an important property as it determines their ability to withstand accidental impacts or external forces during transportation, installation, and operation. The impact toughness of steel pipes is typically evaluated using standardized tests such as the Charpy V-notch test or the Izod test. These tests involve striking a notched sample of the steel pipe with a pendulum or a falling weight and measuring the energy absorbed by the material before it fractures. The impact toughness is then calculated based on this energy absorption. A high impact toughness is desirable in steel pipes as it indicates a greater ability to absorb energy and resist fracture, making them more resistant to sudden impacts or loading conditions. This is particularly important in applications where steel pipes are used in high-stress environments, such as in oil and gas pipelines, automotive components, or structural applications. Various factors can affect the impact toughness of steel pipes, including the chemical composition, heat treatment, and microstructure of the steel. For example, alloying elements like manganese, chromium, and nickel can enhance the impact toughness by promoting the formation of fine-grained microstructures and preventing the propagation of cracks. Similarly, proper heat treatment processes such as quenching and tempering can improve the impact toughness by optimizing the material's microstructure and mechanical properties. In summary, the impact toughness of steel pipes is a crucial property that determines their ability to withstand sudden or high-velocity impacts. It is evaluated through standardized tests and is influenced by factors like chemical composition, heat treatment, and microstructure. A high impact toughness is desirable in steel pipes to ensure their structural integrity and resistance to fracture under dynamic loading conditions.

- Q:What kinds of steel pipe are divided into?

- Welded pipe: also known as welded pipe, is made of steel or steel strip after bending forming, and then made by welding. In accordance with the form of weld is divided into longitudinal welded pipe and spiral welded pipeSpecifically refers to the use of welded steel strip or plate bending deformation of round, square shape after welded, surface jointed steel pipe. The welding steel billets is used in steel plate or strip. The welded pipe production process simple, high production efficiency, great variety, less capital equipment, but since the general strength is less than that of seamless steel.20 century 30s, along with the rapid development of high-quality strip rolling production and progress of welding and testing technology, and constantly improve the weld quality, varieties and specifications of welded steel pipe is increasing, and instead of the seamless steel pipe in more and more fields. Compared with welded steel seamless steel tube with low cost and high production efficiency.

- Q:Galvanized steel pipe, PPR pipe, PE pipe, U-PVC pipe and HDPE double wall corrugated pipe and what is the difference between the characteristics of

- Galvanized steel pipe is a kind of antirust steel pipe, often used in relatively high water supply pipeline or hot water pipeline, the price is higher, can use for at least 30 years;PPR pipe is a kind of polypropylene plastic, which is commonly used in environmental protection plastic pipes, but only suitable for low temperature occasions. It is mainly used for water supply;

- Q:How are steel pipes recycled?

- Steel pipes are recycled through a multi-step process that involves collection, sorting, cleaning, and melting. First, the used steel pipes are gathered from various sources such as construction sites or industrial facilities. Then, they are sorted based on their size, shape, and quality. Next, any contaminants or coatings are removed from the pipes through cleaning and stripping processes. Finally, the cleaned pipes are melted down in a furnace, and the molten steel is formed into new pipes or other steel products. This recycling process reduces the demand for new raw materials and helps conserve energy and resources.

- Q:How do steel pipes handle extreme weather conditions?

- Steel pipes are highly durable and can withstand extreme weather conditions. They have excellent resistance to corrosion, which allows them to maintain their structural integrity even in harsh environments. Additionally, steel pipes have high tensile strength, making them resistant to bending, cracking, or collapsing under extreme weather events such as strong winds, heavy snow, or intense heat. Overall, steel pipes are a reliable choice for handling extreme weather conditions.

- Q:How can galvanized steel pipe be connected with stainless steel pipe?

- The method of non direct fusion is adopted, such as blue, silk head and movable joint

- Q:How do you calculate the maximum allowable deflection for steel pipes?

- The maximum allowable deflection for steel pipes can be calculated using various formulas and guidelines set by industry standards. Factors such as the material properties of the steel, pipe diameter, wall thickness, and the applied load are taken into consideration. These calculations typically involve using equations that relate to the pipe's moment of inertia, modulus of elasticity, and the specific loading conditions. It is recommended to consult relevant engineering codes and standards, such as ASME B31.1 or ASME B31.3, to ensure accurate calculations and safe design.

- Q:Can steel pipes be used for oil and gas pipelines?

- Yes, steel pipes can be used for oil and gas pipelines. Steel pipes are commonly used in the oil and gas industry due to their strength, durability, and resistance to corrosion. They can withstand high pressure and extreme temperatures, making them suitable for transporting oil and gas over long distances.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CS Seamless Steel Pipe ASTM A53/ ASTM A106/ API

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords