Spun Ceramic Fiber Blanket Alumina Silicate 1430C HZ

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 9000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

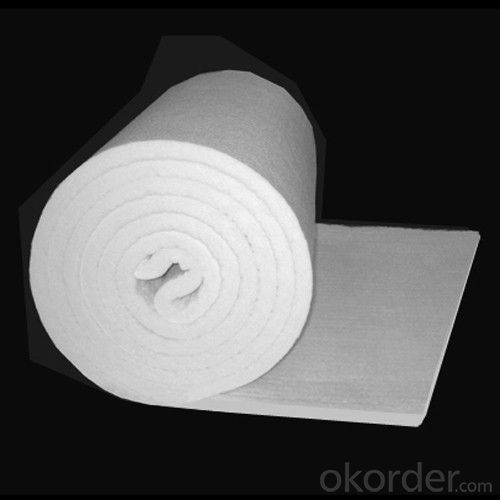

General Information of Ceramic Fiber Blanket

Ceramic fiber blanket aluminum silicate blankets in same volume weight and different thickness, which provides widen range of materials selecting for customers to get the best heat insulation structure and energy-saving effect.

High Zircon aluminum silicate fiber blanket 1430C

Product Sizes and Variants of Ceramic Fiber Blanket

Width: ≤1220mm

Thickness: 6-60mm

Density: 4, 6, 8 lbs./cu. ft. (64, 96, 128 kg/m3)

(Non-standard sizes are available upon request)

Also available with aluminum foil back

Customer Application Notes

Product Handling: Require protective gloves, cloth, mask and dust control.

Characteristics of Ceramic Fiber Blanket

Lightweight

Low thermal conductivity

High temperature stability

Excellent handling strength

Low heat storage

Thermal shock resistance

Chemical and corrosion resistance (commonly used acid and alkali)

Excellent fire protection

Image of Ceramic Fiber Blanket

Technical Data of Ceramic Fiber Blanket

Classification Temperature | 1050 | 1260 | 1400 | ||||

Code | HLGX-112 | HLGX-212 | HLGX-312 | HLGX-422 | HLGX-512 | ||

Shrinkage on Heating (%) | 950°C×24h≤-3 | 1050°C×24h≤-3 | 1100°C×24h≤-3 | 1200°C×24h≤-3 | 1280°C×24h≤-3 | ||

Theoretical Thermal Conductivity (W/m·k)(128kg/m3) | (200°Caverage) | 0.045-0.060 | 0.052-0.070 | ||||

(400°Caverage) | 0.085-0.110 | 0.095-0.120 | |||||

(600°Caverage) | 0.152-0.20 | 0.164-0.210 | |||||

Theoretical Density (kg/m3) | 96/128 | 128 | 96/128 | ||||

Specification (mm) | 3600/7200/15000×610/1220×10/20/25/30/40/50 (422δ: 10/20/25/30) | ||||||

Tensile Strength(25mm thick)MPa | ≥0.04 | ||||||

Package | Plastic Bag Inside, Braided Bag Outside | ||||||

Application of Ceramic Fiber Blanket

Lining, insulation and repair for furnaces, kilns, ovens, boilers;

Insulation for power plant, turbine, thermal reactor, generator, and nuclear applications;

Expansion joint seal and insulation;

Wrapping and insulation for high temperature pipe or metal casting;

Fire protective insulation and lining

Other high temperature seal, gasket, insulation or protection

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q:and what makes more money sculptures or paintings , if the artist is just as good in both.

- If you're saying it went down the clean out trap when you were cleaning the screen of lint, then it's still iside you machineThere is NO WAY a dryer will blow hard enough to push it out through the vent pipeYou'll have to take the back off your machine and get at the piping from your lint trap to the bottom where the piping hooks on.

- Q:What are the types of Fabrics?it's properties uses application Examples.etc.would you give me a lot of GOOD links.Not in the Field of clothing but in the Aviation/Aircraft.Thanks!

- For aircraft applications, most people either use canvas (tightly wrapped over a wooden frame) or a blanket of silk (for parachutes)Most pilots wear synthetic fibres, such as Nomex, for their flight suitsHope this helps!

- Q:My house is facing E-W and getting direct sun all day here in FloridaI just finished siding last Sumer by using a insulation with tight dead air space, my bed room window facing the East has blind shut all day to block the sun, however, my bed room gets hotter than the rest of the room, plus entire indoor house is hotter than even out side especially in the eveningWhy is this, and what can I do ? (do not wish to spend money too much since I just finish putting $30K into this home.

- Fixing the insulation would show the most improvement in terms of heat/cool air retentionMaking sure that there is enough insulation in the attic and outside walls, as well as an adequate vapor barrier would dramatically help with energy savingsPlus, in the mean time, you can do small repairs to windows by removing the old caulking and replacing it.

- Q:is it that it has a nearly perfect thermal blanket?especially given that its days are about a year long, wouldn't you expect a huge difference in temperature?

- you probably don't need a blanket at 45-65 degreesthe general rule is about 25 degrees and below they should have a blanket on on, unless its snowy, rainy, or very windyif you do get a blanket only put it on her when there are conditions as i have mentioned above, and at nightfeed her extra hay at night because the fiber helps her to keep herseld warmI would get a medium weight blanket that is water proofI seriously doubt that it will keep her coat from growing backAnd if by some chance it does, then take it off of her, unless it is 25 degrees and lower, or it's rainy, snowy, or windy; in which case she should have it on.

- Q:What type of yarn or fiber could this be made from?

- do a burn testBefore doing a burn test you should take some safety precautionsAlways work in a well ventilated area—especially important if testing syntheticsUse metal tweezers or tongs to hold the fabric you are burning and make sure you have fire extinguishing materials handy, just in caseOther tips: 1) Don’t do the test when you have sinus problems or a cold and don’t use matches or refillable lighters with a strong fuel smell; a disposable lighter works best—the way the burnt fiber smells is important for identification tooHere’s a basic guideCellulose (Cotton/Linen/Hemp/Rayon/Bamboo): Ignites and burns quickly, may flare, leaves a glowing ember after flame is extinguishedSmoke is white or light colored and smells like burnt paper or leavesAsh is light gray or white and very softProtein (Silk/Wool, Cashmere, Alpaca etc): Burns slowly and shrinks or curls away from the flameWill not stay lit after flame is removedVery little smoke is produced but it smells like burnt hair (wool) or feathers (silk)Ash is a gritty powder or a dark brittle, easily crushable beadSynthetics (Nylon/Polyester/Acrylic): Ignites and burns quickly and can continue to burn after a flame is removed—exercise cautionFiber may shrink from the flame, melt, and can drip (DANGER) leaving a hard plastic-like beadBurning these fabrics will produce black smoke and hazardous fumesNylon smells like plastic when burnt but can also can produce a celery-like smell; Acrylics burn with a strong, acrid, chemical smellPolyester smells slightly sweet, also with a chemical odor.

- Q:My wife is a nymphoI'm in my early fifties and she's in her early thirtiesI was able to keep up when we first met, but now things are a bit different for me, like I can't seem to go everyday most of the day longShe on the otherhand gets frustrated with me constantly, but when I mention about getting male enhancers she objectsI hate to see her unhappy, but my body isn't the young body it use to be, any suggestions - herbal, natural, vitamins?

- No, no longer technicallyIm constantly bored, and my household or peers not ever occcur to me as uninteresting! Bored simply approach you dont have some thing to do:]] Sealed With a Cherry, CherryLuffer.

- Q:It's a very fluffy acrylic sweater and my daughter's favoriteI refused to let my husband wash it but I'm positive it would get ruined.

- I have been cooking for 49 yrsI have used aluminum for all of those yearsI and my family are perfectly healthyThis is getting ridiculousEveryday there is something new that is bad for usPick up any newspaper, magazine, watch tv or go on lineThis is bad for your heart, this causes cancer, this is going to kill youI use cast iron tooI eat seafood, red meat, and anything else I wantThis has nearly ruined meatsButchers now cut off nearly all of the fat and that is where the flavor isPork chops are so dry now!! Give it a rest.

- Q:What are the properties of:Polyester SatinPolyester FleeceCottonVelcrothanks:)

- (2,970 x 5) 14,850j(14,850/28,018) x 100 53% efficiency.

- Q:baby blanket .I am only a beginner.for example dk/chunky etc.

- Check: 1) That it is NOT made in ChinaTheir standards are awfulThere have been instances of dogs dying from eating dog treats made in China, and I would not feed anything made in China to anyone, animal or human2) The best before date on the boxIt won't hurt you if the cake mix has expired, but it might go stale or rancid and not taste goodI once had a bad box of Kraft Dinner that had expired the powdered cheese mix was brown and smelled badI would not buy expired frostingFrosting has ingredients in it that CAN go badCakes can be very good without frosting, you knowMake a sugar-water glaze and add a squirt of lemon juice to it 3) A cake pan is a cake panBy all means buy your 99-cent cake pan.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Spun Ceramic Fiber Blanket Alumina Silicate 1430C HZ

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 9000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords