Cryogenic Micro Fiberglass Insulation Paper for LNG Cylinder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cryogenic Insulation Paper

Cryogenic insulation paper(P paper/Z paper)/aluminum foil(or aluminized polyester film) compositions are laminated of Cryogenic insulation paper and aluminum foil(or aluminized polyester film).These products can be wrapped to the cryogenic inner tank directly and no need to composite by user. Glass fiber Cryogenic & Insulation paper's diameter between 0.1-0.6μm and fiber glass filament (diameter between 3-5 μm). According to a certain proportion, the paper is produced under the wet & vacuum forming process to make the paper have the space lattice structure. All the glass fiber is inorganic material, so it has outstanding flame retardant properties. Specifically engineered for use at big temperature range (approaching -273℃—500℃) and also the paper is really stable in the low temperature condition.

Product Applications:

Cryogenic insulation paper are ideal for use in the below applications

Ladles

Torpedo Ladle

Tundish

Cement Rotary Kiln

Product Advantages:

Aluminum foil composite cryogenic adiabatic paper series products are composed by flame retardant cryogenic adiabatic paper and pure aluminum foil through the multilayer compound composition.When using, the user does not need compound byselvs, thus effectively reduce the customers waste, loss and tooling manufacture in the use of process.In order to speed up the take off and adsorption speed of the cryogenic adiabatic paper material between each layer and the various impurities i gas, which is easy for customers to get very good thermal conductivity in the usage, we may according to the customers’ request, doing punching processing to reflector screen materials.

Main Product Features:

Extremely low thermal conductivity

High compressive strength

High thermal stability

Light weight

Good uniformity

Low thermal conductivity

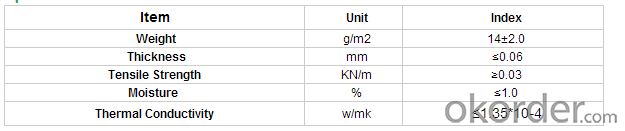

Product Specifications:

FAQ:

Q1: Why buy Cryogenic insulation paper from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3:Can you offers samples?

A3:Of coures,samples are free but freight paid by the buyers.

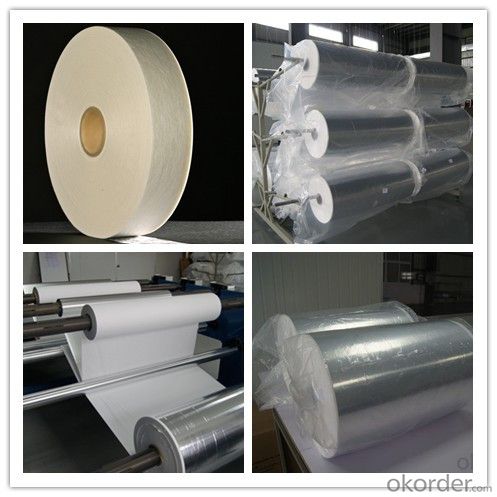

Product Picture

- Q:Ceramic fiber insulation moisture-proof, but also play a cooling effect?

- Then use the compressed air jet or use the wire throwing machine to turn the yarn into a fiber. After the cotton collector sets the cotton, it forms the ceramic fiber cotton.Fiber cotton can be further processed into fiber blanket, board, paper, cloth, rope and other products.

- Q:Why doesn't the insulation effect of ceramic fiber compound reflect the insulation board well?

- And although the ceramic fiber high temperature resistance, but in 1400 degrees when the use of life will be greatly reduced, and the thermal conductivity of the beginning as compound reflection insulation board, high temperature is higher than the compound reflection insulation board greatly.

- Q:Ceramic fiber spray and thrown silk floss, which is better?

- Different applications of two kinds of ceramic fiber cotton:In 1, production of HLGX ceramic fiber module: rejection due to thick and long silk fiber is better than spraying silk carpet, in the block made of the folding process, blowing fiber blankets easily broken and torn, and thrown silk fiber blanket can be folded very closely and not easy to damage, the quality will directly affect the block lining quality;The vertical layer 2, large boiler insulation blanket shop carpet fiber application: rejection due to long and thick, has better tensile resistance, more durable, so the rejection is better than spray carpet carpet;3, application of ceramic fiber textile, silk fiber thick and long and has good spinnability, the ceramic fiber thrown silk became the production of ceramic fiber textiles (cloth, tape, rope, pipe and other special materials);4, HLGX ceramic fiber board, carpet, light heat insulation castable application: blowing short cotton fibers, fine low thermal conductivity is more suitable for dispersed, as ceramic fiber paper, ceramic fiber board and Castable Ceramic Fiber Wet products.

- Q:What's the function of refractory ceramic fiber band?

- Ceramic fiber belt main uses: industrial heat insulation, pipe and cable insulation coating, exhaust pipe insulation coating, flange connection, heat radiation shielding, high temperature furnace door curtain, etc..

- Q:What fiber glass made of ceramic fiber paper?

- Ceramic fiber paper production process is:Beat out - pulp - pulp - long mesh forming - vacuum dehydration - drying - cutting - winding - packaging

- Q:What are the prospects for ceramic fiber paper and how much investment will be needed?.

- It's a good prospect. I have friends around here who specialize in this. Not much investment.

- Q:Is everybody ceramic fiber cotton poisonous?

- Do not contact the skin, dust, mainly do not breathe into. Are two kinds of dangerous goods.So wear gloves and masks when handling.

- Q:Are ceramic fiber paper permeable?

- However, in the case of water can not play a good insulation effect, but the use of ceramic fiber paper temperature is about 1000 degrees, there will be no water, Ji'nan Sheng Yang ceramic fiber manufacturers

- Q:What is ceramic fiber paper? What is ceramic fiber paper for?

- In order to understand what ceramic fiber paper can do, it is necessary to know what product characteristics it has. Only by knowing these advantages can we make accurate judgments about what we can do.The ceramic fiber paper is made of ceramic fiber, so the ceramic fiber paper itself contains no asbestos and can replace the carcinogenic asbestos products on the market.The raw material of the ceramic fiber paper is longer, low density, high strength, and has a certain elasticity, so it is easy to carry out stamping, cutting, winding and other construction operations. It is because of the ceramic fiber paper after high temperature firing process, so it has high temperature resistance, chemical corrosion, thermal shock, low thermal conductivity, good dielectric strength and high elastic modulus and high performance.

- Q:How to paste the ceramic fiber paper on the iron plate?

- Stick on the plate for what you see over the place, or if used in high temperature place, we recommend a special high temperature fireproof glue;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cryogenic Micro Fiberglass Insulation Paper for LNG Cylinder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords