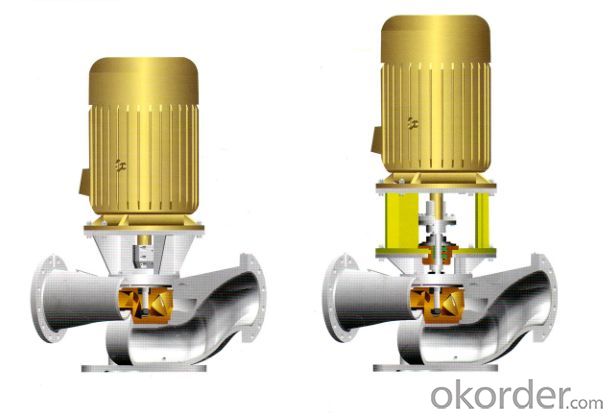

Cryogenic Centrifugal Pump with Single Stage and Suction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Cryogenic Centrifugal Pump with Single Stage and Suction

High-rise buildings, fire protection, refrigeration systems and industrial, agricultural, hotel, deep well

Pumping water, fresh water and sea transport etc.

1, water supply: Water filtration and distribution, water supply main pipe water area, the first increase in pressure,

Increased pressure of high-rise buildings.

2, industrial pressure: Industrial production water system, cleaning system, high pressure washing system, fire protection System.

3, industrial liquid conveying: Cooling and air-conditioning system, boiler feed water and condensate systems, machine

Matching, acidic and alkaline medium transport.

4: Water treatment system, water treatment system, ultrafiltration system, reverse osmosis system distillation system, Separator and a swimming pool.

5, irrigation: Farmland irrigate, sprinkler irrigation, drip irrigation.

Transmission medium of Cryogenic Centrifugal Pump with Single Stage and Suction

1, Non flammable and explosive medium, thin, clean, containing no solid particles or fibers.

2, such as mineral water, softened water, pure water, thin sewage water, food oil and other light industry media.

3, pump the main material for stainless steel, can be used in pumping mildly corrosive media.

Conditions and Performance parameter of Cryogenic Centrifugal Pump with Single Stage and Suction

1. Model specification diameter 20~200 (mm)

2. Pump maximum working pressure: 1.6Mpa

3. Pump shaft: 2Cr13

4. Head: 18 ~ 310 (M)

5. Suction diameter: 65 (mm)

6. Discharge diameter: 65 (mm)

7. Performance: No leakage

8. Use: Booster pump

9. Pump shaft position: Edge of the vertical

10. The structure principle: Jet pump

Transport temperature -20 Centigrade~120 Centigrade corrosive medium or physical, chemical performance similar to water medium.

FAQ

Q: Are CNBM pumps available in DIY stores?

A: Yes, currently, we’re available for DIY stores all over the world.

Q: Where do I have to send pumps for service?

A: You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

Q: Are your pumps acid-proofed?

A: To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

Q: Can your pumps mount Eff.1 motors

A: Currently, only on request though this will shortly be a CNBM standard.

Q: Are your pumps protected against dry running?

A: No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

- Q:Here are specifications for two water pump sets. I would like to know which one will have more vertical suction.Pump 1:1.5 hp, 98cc Engine, 4 - Strokes RPM 3600 (Engine RPM), Petrol Fuel, Fuel Consumption 700 ml/hour, Delivery (horizontal) 50m, Inlet / Outlet Port (Dia) 1.5x1.5 inches, Output Capacity 48000 Litres / Hour.Pump 2:3.3hp, 163 cc Engine, 4 - Strokes RPM 3600 (Engine RPM), Petrol Start amp; Kerosene Run, Fuel Consumption 700 ml/hour, Delivery (horizontal) 26m, Inlet / Outlet Port (Dia) 2x2 inches Output Capacity 36000 Litres / Hour.which one should I go for.

- Neither one if you are trying for more than about 32 feet (10 meters) because movement of water is determined by air pressure and the vacuum/suck and the former limiting. Pumps that move water vertically more that 30 feet or so PUSH the water. Which is why well pumps of any depth are hung on the end of the riser pipe with a power cable running down to them.

- Q:If a submersible pump to shake the insulation, water pump distance more than 20 meters away from the cable distribution box is fixed, at this time to shake the insulation in the distance distribution box can only shake, disconnect the power cable is connected with the shake table, the ground end is connected with the distribution box in such a shake, I want to ask is, what is this shake is not the pump shell must be reliable grounding to shake ah? Now the pump casing is not grounded, just immersed in water, immersed in the water, is not equal to good grounding ah?

- A submersible pump to shake the insulation, water pump distance more than 20 meters away from the cable distribution box is fixed, at this time to shake the insulation in the distance distribution box can only shake, disconnect the power cable is connected with the shake table, the ground end is connected with the electric box so that the pump shell shake shake, also must be reliable grounding to shake to now, the pump shell grounding not only in the water, it must be a wire connected with a shell or a wire will be immersed in water, this is right insulating shake,

- Q:How can I test to be sure my water pump is working before I go to the lake and burn up my motor. `72 65hp johnson. thank you.

- You can also go to a marina and buy earmuffs that hook to a garden hose and fit over your water intake. As stated above just look for a stream of water coming out the back of the engine.

- Q:it is a mazda b3000 pick up v6,it is coming from behind water pump,but it is not all the time, i would think that if pump is going it would be all the time, but it will go bone dry for a few dayswhen it does leak it leaves about an 8 inch spot on the driveway,temp gauge goes to its regular spot and does not move,any suggestions would be helpful,thanks

- stop feeding the neiborhood cats antifreeze thats why there looking mangey look let the car warm up or top it off and come back you have to figure when it leaks dont check it when its hot have it replaced dont overlook the obvious dont work with out jack stands dont operate on just a jack and wear your safty glasses check the chilsons website use metric

- Q:We had a thunderstorm followed by power outage last night, this morning I went to use the water and it slowly went dead.I began by inspecting the pressure tank and pressure control switch, then found the outside water pump breaker was tripped, upon resetting the water was back on!But wait, after about 1-2 minutes of use there was a small quot;POPand smoke from the control switch and the breaker tripped again. It seems now that every time the water pump kicks in I've got a 50/50 shot of the circuit breaker blowing. I'm not sure what to do now, I don't want to keep resetting my pump breaker, we really didn't get that much rain so I don't know what would be causing this issue?Any help would be greatly appreciated.Thanks!

- So, you say you have a 50/50 chance of the water pump's breaker popping out when you use it now. I would assume you mean when you've used it enough to make the pump come back on. Actually, I think I'd start by replacing the pressure switch, regardless of which system you have, submersible or above ground, the pressure switch will be where it can be serviced. I really can't think of any reason why a pressure switch would cause a breaker to trip, but at least that way you'd know you've done all you can do. If your system is a submersible you'll have to have a water company come out with a boom truck to pull that pump up out of the ground.

- Q:looking for the comparison and then finaly the conclusion about the water pumps instaaled in the IC engines. Where we should stick to the tradional mechanical driven water pumps or electrical water pumps? which one is better!! any information/ response is appreciated

- Duh (I have to assume that IC = a engine (as fitted in a car) if there's no fan belt, how would YOU drive a water pump? I suggest the person that asked the question has PEDALS fitted to his/her IC the fan belt went when radiator fans had motors added (which was good as the fan was a unwanted load on the engine ...you only need a fan when stationary)

- Q:I am trying to change my daughters 2004 Grande Am water pump because people tell me it is squealing. We purchased a replacement pump and blue gasket glue. I know to remove the Serpentine belt (not sure which pulley to reduce tension on) then I need to know which bolts to un-tighten, won't the pump turn as a use the wrench? Is there a good video available on changing out the water pump? I've done maybe 5 water pumps in my lifetime all on V-8s with rear wheel drive, so they had easy access. Does anyone know the steps of removal or can someone point to a video of removal replacement?

- better make sure it,s not the belt squealing and not the pump. usually when a water pump goes out they will leak. i would be checking the belt first.

- Q:I would like to have a water pump/valve that I can tie into my house water and will run on a timer. Kind of like a sprinkler system but not so expensive an on a much smaller scale. Basically what I am trying to do is set up an auto-watering (from the tap) system for my animals when I am away for a day or two. I know this is more in the lines of a pet category but than again - not really.

- Most self watering devices for animals don't use a timer. Imagine a big coffee can with no lid, with a small hole on the side near the lip. Fill the coffee can with water, place a pie tin over the coffee can opening, and flip them both over. The pie tin will fill with water for awhile, but only until it covers the hole in the side of the coffee can. At that point, air can't get into the coffee can, therefore water can't get out of the coffee can. Your pets will drink out of the pie tin. When the water level falls below the hole in the side of the can, a little air gets in, and a little water gets out. So water will be available on demand for your pets until the coffee can is empty. A coffee can holds nearly a gallon of water, and being short and squatty your pets won't knock it over. Fun science project.

- Q:1.5KW water pump caliber is 40, what is the flow rate?

- Because you provide a wide range of data, there are several models and lift and flow, if you are interested, please leave a message for me to communicate

- Q:does anyone know how a water pump works????????????

- There are many types of water pumps. What type are you interested in?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cryogenic Centrifugal Pump with Single Stage and Suction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords