Crimped Wire Mesh for Filtering Customised Size with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 250000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Crimped Wire Mesh for Filtering Customised Size with High Quality Description:

Welded wire mesh is also can be called welded wire mesh sheet or welded wire mesh roll according to its making methods. It is one of the most versatile of all wire mesh.

Widely used in industry, agriculture, building, mine, decoration etc.

Materials: high quality low carbon steel wire, stainless steel wire.

Coating style: Electro Galvanized before welding, Electro Galvanized after welding, Hot dipped galvanized before welding, Hot dipped galvanized after welding, PVC coated.

Zinc coating: 20-250g/m2

2.Main Features of Crimped Wire Mesh for Filtering Customised Size with High Quality :

• Versatile, High strength, Easy cutting and shearing, Solid construction, Welding point stronger, Easy handling, corrosion- resisting, oxidation-resisting.

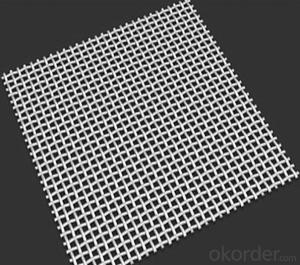

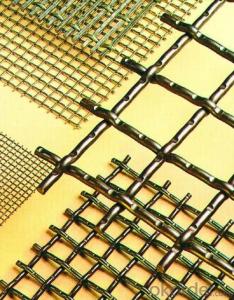

3.Crimped Wire Mesh for Filtering Customised Size with High Quality Images

4.Crimped Wire Mesh for Filtering Customised Size with High Quality Specification

Specification List of Welded Wire Mesh | |||||||||

Opening | Wire Diameter | ||||||||

In inch | In metric unit(mm) | ||||||||

1/4" x 1/4" | 6.4mm x 6.4mm | 22,23,24 | |||||||

3/8" x 3/8" | 10.6mm x 10.6mm | 19,20,21,22 | |||||||

1/2" x 1/2" | 12.7mm x 12.7mm | 16,17,18,19,20,21,22,23 | |||||||

5/8" x 5/8" | 16mm x 16mm | 18,19,20,21, | |||||||

3/4" x 3/4" | 19.1mm x 19.1mm | 16,17,18,19,20,21 | |||||||

1" x 1/2" | 254mm x 12.7mm | 16,17,18,19,20,21 | |||||||

1-1/2" x 1-1/2" | 38mm x 38mm | 14,15,16,17,18,19 | |||||||

1" x 2" | 25.4mm x 50.8mm | 14,15,16 | |||||||

2" x 2" | 50.8mm x 50.8mm | 12,13,14,15,16 | |||||||

Technical Note: | |||||||||

Specification of galvanized hexagonal wire mesh | |||||||||

Specifications | Wire Diameter | Width | |||||||

Mesh(inch) | Size(mm) | Limit Error | BWG | Metric | BS | Metric | |||

3/8” | 10 | +0.5 | BWG27-23 | 0.40-0.6mm | 1”-6” | 0.1-2m | |||

1/2” | 13 | -1.5 | BWG27-22 | 0.4-0.7mm | 1”-6” | 0.1-2m | |||

5/8” | 16 | +1.0/-2.0 | BWG27-22 | 0.4-0.7mm | 1”-6” | 0.1-2m | |||

3/4” | 20 | +1.0/-2.5 | BWG26-20 | 0.46-0.9mm | 1”-6” | 0.1-2m | |||

1” | 25 | +1.5 | BWG25-19 | 0.5-1.0mm | 1”-6” | 0.1-2m | |||

1-1/4” | 31 | -3.0 | BWG24-18 | 0.56-1.2mm | 1”-6” | 0.2-2m | |||

1-1/2” | 40 | +2.0/-4.0 | BWG23-16 | 0.6-1.65mm | 1”-6” | 0.2-2m | |||

2” | 51 | +2.0/-4.0 | BWG22-14 | 0.7-2.0mm | 1”-6” | 0.2-2m | |||

3” | 76 | +2.0/-4.0 | BWG21-14 | 0.8-2.0mm | 1”-6” | 0.3-2m | |||

4” | 100 | +2.0/-4.0 | BWG20-12 | 0.9-2.8mm | 1”-6” | 0.5-2m | |||

Others we can do as your requirement | |||||||||

Specification of PVC coated hexagonal wire mesh | ||

Opening | Wire Diameter | |

Inch | MM | MM |

1/2” | 13mm | 0.6mm-1.0mm |

3/4” | 20mm | 0.8mm-1.1mm |

1” | 25mm | 0.9mm-1.4mm |

1-1/4” | 30mm | 0.9mm-1.5mm |

1-1/2” | 40mm | 0.9mm-1.5mm |

2” | 50mm | 0.9mm-1.5mm |

Others we can do as your requirement | ||

Mesh/inch | Wire Dia. (mm) | Aperture (mm) |

2 | 1.60 | 11.10 |

4 | 1.20 | 5.15 |

5 | 1.00 | 4.08 |

6 | 0.80 | 3.43 |

8 | 0.60 | 2.57 |

10 | 0.55 | 1.99 |

12 | 0.50 | 1.61 |

14 | 0.45 | 1.36 |

16 | 0.40 | 1.19 |

18 | 0.35 | 1.06 |

20 | 0.30 | 0.97 |

30 | 0.25 | 0.59 |

40 | 0.20 | 0.44 |

50 | 0.16 | 0.35 |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Crimped Wire Mesh for Filtering Customised Size with High Quality?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional UAE Market Electric Galvanised Wire BWG 20 0.7mm Hot Dipped Galvnised Wire factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②What is your Technical Information of Crimped Wire Mesh for Filtering Customised Size with High Quality ?

1).Material: super carbon steel

2).Processing by drawing, hot-dip zinc-plating

3).Standard wire gauge from 8# to 24#

4).Thick zinc-coating layer

5).Super in corrosion resistance

6).Firm coating layer

7).Custom size available

Crimped Wire Mesh for Filtering Customised Size with High Quality

③How long can we receive the product after payment?

In the purchase of Galvanized Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

Crimped Wire Mesh for Filtering Customised Size with High Quality

- Q:What is the screen printing plate?

- Is a certain tension by the tension of the screen after the tension on a frame, and then coated with a photoresist on the top and then with a specific pattern of film with UV light after the light washed out of the pattern made of water.

- Q:Is the screen printing the best way? And other printing methods than it?

- Screen printing is the most adaptable in all printing methods. Ink layer thickest, good hiding power, the best durability, full of bright graphics, other printing methods can not be replaced. Generally used for outdoor advertising, transfer flower paper, electronic lines, glass cloth and other special industries

- Q:What are the characteristics of screen printing?

- Screen printing is widely used in China's electronics industry, ceramic decals industry, textile printing and dyeing industry and packaging and decoration, advertising, posters and other industries, as the screen printing is much more than other printing methods have many unique advantages.

- Q:What is the principle of screen printing?

- Type of printing: no printing - such as inkjet, electrostatic copying, laser. Printed - such as movable type, off, screen.

- Q:What are the reasons for the hair making of the screen plate?

- Film thickness to touch the edge of the brush slightly raised the feel is better. (Coating method can be used in this way to try: screen inside coated 2-3 times, and then dry, to be completely dry After the screen outside the continuous coating 2-3 times. (Outside the number of coating can be based on the final thickness of the corresponding increase or decrease)

- Q:Screen printing, how to print circular arc surface

- If the ink transferred to the cup on the lighter, it may be necessary to add ink, or produce blocking network.

- Q:The difference between screen printing characteristics

- Advertising, curtains, curtains. For example, the current general offset printing, embossing and other printing methods can print the size of the largest size of the whole sheet, more than the full size, it is subject to mechanical equipment restrictions.

- Q:What is the commonly used mapping software for screen printing?

- screen printing is a stencil printing, it is printed with India, embossing, gravure together known as the four printing methods. The stencil printing includes transcripts, engravings, stencils and screen printing.

- Q:How to get the correct fishing wire

- Screen (sticky net) used in a narrow place, the best night net, pay attention to the depth of water, the Internet is not too heavy too heavy. Can sink on the line.

- Q:Screen printing ink firmness problem

- Screen printing rarely use water-based ink, because the water-based ink in the non-absorbent substrate adhesion fastness is usually much worse than the solvent-based ink, plus silk ink layer thick, adhesion is more problematic.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Crimped Wire Mesh for Filtering Customised Size with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 250000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords