CPVC END CAP ASTM D2846 1/2 to 2 CPVC Plastic Cap

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Quick Details | |

| Material: Plastic | Connection: glue |

| Technics: injection | Shape: Equal |

| Type: Cap | Head Code: round |

| Place of Origin: China (Mainland) | Color: beige |

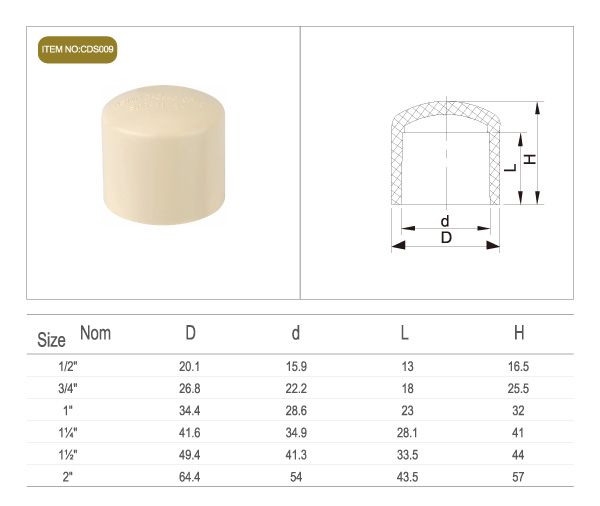

| Model Number: CDS009 | Size: 1/2"~2" |

| Certification: NSF, ASTM D2846 |

| Packaging & Delivery | |

| Packaging Details: | 51.5*40*550px; 49*39*950px; 39*25.5*625px |

| PE poly bag+ carton | |

| 385-1130 CTNS/ 20 CONTAINER; 935-2740 CTNS/ 40HQ | |

| Delivery Detail: | 15 days. |

Specifications

Material: CPVC

Standard: ASTM D-2846

Pressure: PN25(2.5Mpa)

Size: 1/2"-2";

Color: beige

Certificate: ISO9001, ISO14001,NSF

CPVC END CAP

1.material CPVC

2.size:1/2"to2"

3.standard:ASTM D-2846

4.Certification:ISO9001 ISO14001,NSF

5.best price,excellent quality,quick delivery

Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Light weight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Extremely long usage life for at least 50 years

- Q:What are the advantages of using plastic pipe fittings?

- Some advantages of using plastic pipe fittings include their durability, corrosion resistance, ease of installation, and affordability. Plastic pipe fittings are highly resistant to chemicals, making them suitable for a wide range of applications. They are also lightweight, making transportation and handling much easier. Plastic pipe fittings are often less expensive than their metal counterparts, making them a cost-effective choice. Additionally, plastic fittings can be easily and quickly installed, reducing labor and installation time.

- Q:Are plastic pipe fittings resistant to solvents?

- Yes, plastic pipe fittings are generally resistant to solvents.

- Q:Can plastic pipe fittings be used for medical gas systems?

- No, plastic pipe fittings should not be used for medical gas systems. These systems require materials that are specifically designed and approved for medical use, such as copper or stainless steel fittings, to ensure the safety and integrity of the gas supply. Plastic fittings may not be able to withstand the high pressures and potential hazards associated with medical gases.

- Q:Can plastic pipe fittings be used in geothermal systems?

- Yes, plastic pipe fittings can be used in geothermal systems. Plastic fittings are commonly used in geothermal systems due to their durability, resistance to corrosion, and ease of installation. They are also cost-effective and provide good thermal conductivity, making them suitable for use in geothermal applications.

- Q:Are plastic pipe fittings suitable for chemical transfer applications?

- Yes, plastic pipe fittings can be suitable for chemical transfer applications. However, it is important to select the appropriate type of plastic material that is resistant to the specific chemicals being transferred. This will ensure the fittings can withstand the chemical exposure and prevent any leaks or potential contamination. Additionally, proper installation and regular maintenance are crucial to ensure the longevity and effectiveness of plastic pipe fittings in chemical transfer applications.

- Q:Can plastic pipe fittings be used in water treatment systems?

- Yes, plastic pipe fittings can be used in water treatment systems. Plastic pipe fittings are commonly used in water treatment systems due to their durability, corrosion resistance, and cost-effectiveness. They can effectively handle the flow of water and withstand the harsh chemical environments often found in water treatment processes.

- Q:Are plastic pipe fittings cost-effective?

- Yes, plastic pipe fittings are generally considered cost-effective due to their low initial cost, durability, and long lifespan. They also require minimal maintenance and offer excellent resistance to corrosion, making them a reliable and affordable choice for various plumbing and piping applications.

- Q:Can plastic pipe fittings be used for pneumatic conveying systems?

- Yes, plastic pipe fittings can be used for pneumatic conveying systems. Plastic pipe fittings, such as PVC or HDPE, are commonly used in pneumatic conveying systems due to their lightweight, corrosion resistance, and cost-effectiveness. They provide a reliable and durable solution for conveying materials in pneumatic systems. However, it is important to select fittings that are specifically designed for pneumatic conveying applications and ensure they can handle the required pressure and flow rates.

- Q:Are plastic pipe fittings suitable for pneumatic conveying systems?

- Yes, plastic pipe fittings are suitable for pneumatic conveying systems. They offer several advantages such as corrosion resistance, lightweight construction, ease of installation, and flexibility. Additionally, plastic fittings can handle the high pressures and abrasive materials commonly found in pneumatic conveying systems.

- Q:How do plastic pipe fittings compare to brass fittings?

- Plastic pipe fittings are generally more affordable and easier to install compared to brass fittings. However, brass fittings are known for their durability, higher resistance to heat and pressure, and better overall performance in terms of longevity. It ultimately depends on the specific needs and budget of the project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CPVC END CAP ASTM D2846 1/2 to 2 CPVC Plastic Cap

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords