CPC Low Sulfur Petroleum Coke FC 98% Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 50kg/bag 100kg/bag 1000kg/bag Or according with client need to do |

| Delivery Detail: | 2 weeks |

Specifications

CPC Low Sulfur Petroleum Coke FC 98% Cheap Price

Petroleum coke products can be divided into needle coke, sponge coke, projectile coke and coke breeze four kinds.

Calcined Petroleum Coke

F.C.: 98.5%MIN

ASH: 0.8% MAX

V.M.: 0.7%MAX

S:0.5%MAX

Moisture: 0.5%MAX

Structure

CPC Low Sulfur Petroleum Coke FC 98% Cheap Price

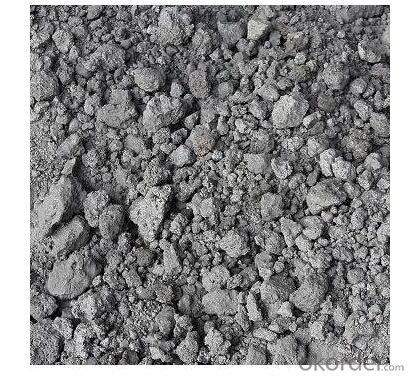

Shape: granule

Dimensions: 0-1mm, 1-5mm, 1-6mm, 2-8mm, etc

Product Type: Carbon Additive

C Content (%): 98-99.5% MIN

Working Temperature: -

S Content (%): 0.5%-0.7%MAX

Ash Content (%): 0.7%MAX

Volatile:0.8%MAX

Moisture: 0.5% MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

Feature

CPC Low Sulfur Petroleum Coke FC 98% Cheap Price

Physics and chemistry performance :

Unit | Index | |||||

No.1 | No.2 | No.3 | ||||

Density | g/cm3 | 2.04 | 2.00 | 2.00 | ||

sulphur content | %≤ | 0.5 | 1.0 | 2.5 | ||

volatility | %≤ | 0.5 | 0.5 | 0.5 | ||

ash content | %≤ | 0.5 | 0.5 | 0.5 | ||

moisture | %≤ | 0.3 | 0.5 | 0.5 | ||

charcoal | %≤ | 98.5 | 98.0 | 98.0 | ||

Image

CPC Low Sulfur Petroleum Coke FC 98% Cheap Price

FAQ:

CPC Low Sulfur Petroleum Coke FC 98% Cheap Price

How to classify calcined petroleum coke?

1) According to difference of sulfur content, can be divided into high sulfur coke (sulfur content more than 4%), sulphur in coke sulfur content (2% 4%) and low sulfur coke (sulfur content below 2%).

2) Petroleum coke products can be divided into needle coke, sponge coke, projectile coke and coke breeze four kinds:

3) Needle coke, has obvious needle-like structure and fiber texture, mainly used for steel-making in high power and ultra-high power graphite electrode. As a result of needle coke in sulfur content, ash content, volatile matter and true density and so on have strict quality requirements, so the production process of needle coke and raw materials have special requirements.

4) The sponge coke, high chemical reactivity, low content of impurities, mainly used in the aluminum industry and carbon industry.

5) Focal or spherical coke: the projectile shape is round, diameter 0.6-30 mm, usually from the production of high sulphur, high asphaltic residual oil, can only be used as industrial fuel power generation, cement etc.

6) Coke breeze: fluidized coking process, the fine particles (0.1- 0.4 mm) in diameter, high volatile, high expansion coefficient, cannot be directly used for electrode preparation and carbon industry.

Advantage:

CPC Low Sulfur Petroleum Coke FC 98% Cheap Price

1. High quality and competitive price.

2. Timely delivery.

3. If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q:Are carbon fibers organic polymer materials?

- No, carbon fiber is not an organic polymer material, and carbon fiber is an inorganic polymer materialOrganic polymer compounds referred to as polymer compound or polymer, also known as polymer is composed of one or several structural units repeatedly (103~105) compound repeat connected. Their elements are not many, mainly carbon, hydrogen, oxygen and nitrogen, but the molecular weight is large, generally above 10000, high millions.

- Q:What are the consequences of increased carbon emissions on cultural heritage sites?

- Increased carbon emissions can have significant consequences on cultural heritage sites. One of the most immediate and visible impacts is the deterioration of physical structures and artifacts. Carbon emissions contribute to air pollution, which can result in the formation of acid rain. Acid rain contains high levels of sulfuric and nitric acids that can corrode and erode materials such as stone, metal, and paint. This can lead to the degradation and discoloration of historic buildings, monuments, and sculptures. Furthermore, carbon emissions contribute to climate change, resulting in more frequent and severe weather events such as hurricanes, floods, and wildfires. These extreme weather events pose a direct threat to cultural heritage sites, causing physical damage and destruction. For example, rising sea levels due to climate change can lead to the erosion of coastal archaeological sites, causing the loss of valuable historical artifacts and structures. In addition to the physical impacts, increased carbon emissions also pose a threat to the intangible aspects of cultural heritage. Climate change disrupts ecosystems and biodiversity, affecting the natural surroundings of cultural sites. This can lead to the loss of traditional knowledge, practices, and cultural landscapes that are closely linked to the heritage sites. Indigenous communities, for instance, may lose their ancestral lands and sacred sites due to changing environmental conditions. Moreover, cultural heritage sites often rely on tourism as a source of income and conservation funding. However, increased carbon emissions contribute to global warming, which in turn can lead to changes in travel patterns and preferences. This can result in a decline in tourist visits to cultural heritage sites, impacting local economies and hindering conservation efforts. Overall, the consequences of increased carbon emissions on cultural heritage sites are multi-faceted and wide-ranging. It is crucial to address and mitigate these emissions through sustainable practices and policies to protect and preserve our shared cultural heritage for future generations.

- Q:What are the problems that should be paid attention to in the injection molding of the material? Who has some details about carbon fiber injection? Thank you for sharing

- Carbon fiber melting point at about 3000 degrees (isolation oxygen, oxygen, about 400 degrees will be oxidized), itself can not be injection processing, only carbon fiber filled plastic can be injection molding.

- Q:How does carbon impact the stability of desert ecosystems?

- Carbon can have both positive and negative impacts on the stability of desert ecosystems. On one hand, carbon is an essential element for all living organisms and is a key component of organic matter. It plays a crucial role in the processes of photosynthesis, respiration, and decomposition, which are vital for the survival and growth of plants and other organisms in deserts. Carbon dioxide, a form of carbon, is taken in by plants during photosynthesis to produce glucose and oxygen, providing the necessary energy for their growth. This promotes the stability of desert ecosystems by supporting primary productivity and the food web. However, the excessive release of carbon into the atmosphere, primarily through human activities such as burning fossil fuels and deforestation, has led to an increase in greenhouse gases, including carbon dioxide. This leads to global warming and climate change, which have significant negative impacts on desert ecosystems. Rising temperatures can alter the delicate balance of desert ecosystems, affecting the distribution and abundance of plant and animal species. Some plants may struggle to adapt to the changing climate, while others may benefit, leading to shifts in species composition and potential loss of biodiversity. Moreover, increased carbon dioxide levels can also affect the water availability in desert ecosystems. Elevated carbon dioxide levels can result in increased water-use efficiency in plants, allowing them to conserve water. This can be beneficial in water-limited environments like deserts, as it helps plants to survive under drought conditions. However, this can also lead to changes in water dynamics, impacting the availability of water resources for other organisms in the ecosystem. In summary, carbon is essential for the stability of desert ecosystems as it supports primary productivity and the functioning of food webs. However, the excessive release of carbon into the atmosphere contributes to climate change, which negatively impacts desert ecosystems by altering species distribution, reducing biodiversity, and affecting water availability. It is crucial to mitigate carbon emissions and promote sustainable practices to ensure the long-term stability and resilience of desert ecosystems.

- Q:How is carbon used in the production of solar cells?

- Carbon is not directly used in the production of solar cells. Solar cells are typically made of semiconductor materials like silicon or cadmium telluride. However, carbon-based materials can play a crucial role in enhancing the performance and efficiency of solar cells. One way carbon is used is in the form of carbon nanotubes, which can be used as a transparent electrode in solar cells. Carbon nanotubes have excellent electrical conductivity and optical transparency, making them an ideal candidate for replacing traditional transparent conductive materials like indium tin oxide. Additionally, carbon-based materials can be used as a coating or encapsulation layer, providing protection to the solar cells from moisture, corrosion, and mechanical stress. Carbon-based materials also have the potential to be used in the development of next-generation solar cell technologies, such as organic solar cells or perovskite solar cells, which utilize carbon-based compounds in their active layers. Overall, while carbon may not be directly used in the production of solar cells, it plays a crucial role in improving their performance and enabling the development of more advanced solar cell technologies.

- Q:How is carbon used in the production of carbon nanomaterials?

- Carbon is used as the raw material for the production of carbon nanomaterials. Different forms of carbon, such as graphite or carbon black, are transformed through various processes like chemical vapor deposition or arc discharge to create carbon nanotubes or graphene.

- Q:Why carbon fiber resistant to low temperature

- Therefore, the carbon fiber composite core can be used in the design and manufacture of transmission carriers under extremely cold conditions, such as Antarctic research and research.

- Q:Advantages of carbon fiber

- Carbon fiber axial strength and high modulus, no creep, fatigue resistance, between heat and electrical conductivity between the metal and non metal, low thermal expansion coefficient, good corrosion resistance, low fiber density, good permeability of X ray.

- Q:How is carbon used in water filtration systems?

- Carbon is commonly used in water filtration systems due to its impressive adsorption properties. Adsorption involves the molecules of a substance binding to the surface of another material, in this case, carbon. Activated carbon, which is carbon that has been specially processed to create a large surface area, is particularly effective in water filtration. When water passes through the filtration system, the carbon captures and retains a wide range of impurities, including organic compounds, chlorine, volatile organic compounds (VOCs), and certain heavy metals. This adsorption process helps to remove unpleasant odors and tastes from the water, making it more palatable. Carbon also plays a crucial role in removing potentially harmful contaminants such as pesticides, herbicides, and pharmaceutical residues. Additionally, carbon filtration systems can help reduce the risk of waterborne illnesses by removing bacteria, viruses, and parasites. Overall, carbon is an essential component of water filtration systems as it significantly improves the quality and safety of drinking water.

- Q:What are the different types of carbon-based pigments?

- There are several different types of carbon-based pigments that are widely used in various industries. Some of the most common types include carbon black, graphite, charcoal, and lampblack. Carbon black is a highly pure form of carbon that is produced by the incomplete combustion of hydrocarbon fuels. It is the most widely used carbon-based pigment and is known for its intense black color. Carbon black is used in a wide range of applications, including inks, paints, plastics, and rubber products. Graphite is another important carbon-based pigment that is known for its dark gray to black color. It is a soft and brittle material that can be easily crushed into a fine powder. Graphite is used primarily in pencils, as it leaves a smooth and consistent mark on paper. It is also used in other applications such as lubricants, batteries, and electrical conductors. Charcoal is a carbon-based pigment that is produced by burning wood or other organic materials in the absence of oxygen. It is known for its deep black color and is commonly used in art as a drawing medium. Charcoal can be easily manipulated and smudged on paper, allowing artists to create a wide range of tones and textures. Lampblack, also known as carbon black or soot, is a pigment that is produced by burning organic materials such as oil or wood. It has a deep black color and is often used in printing inks, coatings, and dyes. Lampblack is also used in various industrial applications, including as a coloring agent in plastics and rubber products. These are just a few examples of the different types of carbon-based pigments that are commonly used. Each type has its own unique properties and applications, making them versatile and essential in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CPC Low Sulfur Petroleum Coke FC 98% Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords