Coupler Scaffolding Clamp Formwork Stage Lighting Scaffolding Cnbm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Coupler Scaffolding Clamp Formwork Stage Lighting Scaffolding CNBM

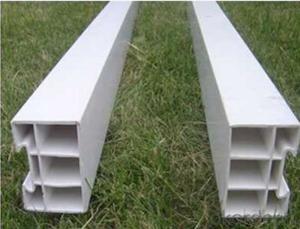

Plastic Formwork Concrete Formwork Circular Column Used Scaffolding Props New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

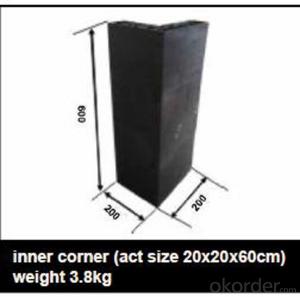

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

The system needs no cut and nail due to the variety size. Also it needs nearly no wood. The material can be recycled after broken, so it will not pollute the environment.

6.Consequent

Concrete does not stick to plastic formwork, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which build by modular formwork is smooth and without rework.

Coupler Scaffolding Clamp Formwork Stage Lighting Scaffolding CNBM

Coupler Scaffolding Clamp Formwork Stage Lighting Scaffolding CNBM

Coupler Scaffolding Clamp Formwork Stage Lighting Scaffolding CNBM

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Stable and durable thanks to its structual design & automatic welding quality

* Customized solution helps you work safe, save cost and convenient

* Excellent quality for formwork & scaffolding with wide choices

Coupler Scaffolding Clamp Formwork Stage Lighting Scaffolding CNBM

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port. For goods with stock, it would be even shoter.

Other scaffolding & formwork products:

(1) Scaffolding System:

Including Ringlock Scaffolding System and accessories; Cuplock Scaffolding System and accessories; Kwikstage Scaffolding System and accessories; Haki Scaffolding System and accessories;

(2) Scaffolding Frame & Accessories:

Including Walk Through Frame Scaffolding; Ladder Frame Scaffolding; Accessories; we also can make scaffolding according to your samples or drawings.

(3) Scaffolding Couplers/Clamps:

We can produce all kinds of forged and pressed couplers, including British type couplers, American type couplers, German type couplers, Italian type couplers ,fence couplers, BRC coplers and so on. We also can produce according to your drawings or samples.

(4) Formwork System Scaffolding & Accessories:

Light Duty Shoring prop and Heavy Duty Shoring Prop; Wing nuts and Tie rods; RASTO clamp and so on.

FAQ Coupler Scaffolding Clamp Formwork Stage Lighting Scaffolding CNBM

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q:What are the key considerations for selecting the appropriate steel frame formwork contractor?

- When selecting the appropriate steel frame formwork contractor, there are several key considerations that should be taken into account. These considerations include the contractor's experience and expertise, their track record and reputation, their safety record, their pricing and value for money, and their ability to meet project deadlines. Firstly, it is important to assess the contractor's experience and expertise in steel frame formwork. This can be done by reviewing their portfolio of past projects, as well as their qualifications and certifications. A contractor with extensive experience in steel frame formwork will have the necessary skills and knowledge to handle the complexities of the job efficiently and effectively. Secondly, the contractor's track record and reputation should be carefully evaluated. This can be done by checking references and reading reviews or testimonials from previous clients. A contractor with a solid track record and positive reputation is more likely to deliver high-quality work and provide excellent customer service. Safety is another crucial consideration when selecting a steel frame formwork contractor. It is important to ensure that the contractor has a strong safety record and follows all necessary safety protocols. This can be determined by reviewing their safety certifications and asking about their safety procedures and training programs. Pricing and value for money are also important considerations. While it is natural to want to find the most cost-effective option, it is equally important to consider the quality of work and materials provided by the contractor. It is recommended to obtain multiple quotes and compare them, taking into account the contractor's experience, reputation, and the scope of the project. Finally, the contractor's ability to meet project deadlines should be considered. It is important to ensure that the contractor has the capacity and resources to complete the project within the specified timeframe. This can be determined by discussing project timelines and deadlines with the contractor and assessing their project management capabilities. In conclusion, selecting the appropriate steel frame formwork contractor requires careful consideration of their experience, track record, safety record, pricing, and ability to meet project deadlines. By evaluating these key factors, you can make an informed decision and choose a contractor that will deliver high-quality work and meet your project requirements.

- Q:How does steel frame formwork help in achieving accurate dimensions?

- Steel frame formwork helps in achieving accurate dimensions by providing a rigid and stable structure that ensures precise alignment and positioning of the concrete elements. The steel frames act as a guide and support system, allowing for consistent and uniform pouring of the concrete. Additionally, the inherent strength of steel minimizes any flexing or movement during the pouring and curing process, resulting in accurately measured and dimensioned concrete structures.

- Q:What are the considerations for selecting the appropriate formwork height and width?

- The considerations for selecting the appropriate formwork height and width include the structural requirements of the project, the load-bearing capacity of the formwork materials, the desired finish of the concrete surface, the accessibility for workers, and the ease of installation and removal. Additionally, the formwork dimensions should be chosen based on the size and shape of the concrete elements being formed, while also taking into account any architectural or design specifications.

- Q:Can steel frame formwork be used for both straight and curved staircase construction?

- Indeed, the utilization of steel frame formwork is applicable for the construction of both straight and curved staircases. This adaptable and pliable solution allows for effortless adjustments to accommodate diverse shapes and designs. By providing the essential support and structure during the construction phase, it enables the creation of both straight and curved staircases. The steel frame formwork system can be tailored and molded to mirror the desired curvature of the staircase, guaranteeing meticulous and precise construction. Moreover, steel frame formwork ensures durability and robustness, rendering it suitable for a myriad of construction projects, including staircase construction.

- Q:What are the lead times for manufacturing steel frame formwork?

- The lead times for manufacturing steel frame formwork can vary depending on several factors. These factors include the complexity of the design, the quantity required, the availability of raw materials, and the current workload of the manufacturer. In general, smaller and less complex steel frame formwork orders can have lead times ranging from a few days to a couple of weeks. This is because these orders can usually be completed relatively quickly and do not require extensive fabrication processes. On the other hand, larger and more intricate steel frame formwork orders may have lead times of several weeks or even months. These orders often require more time for design, engineering, fabrication, and quality control processes. Additionally, if there is a high demand for steel frame formwork or if the manufacturer is experiencing a heavy workload, the lead times can be extended even further. It is important to note that lead times can also be influenced by external factors such as transportation delays, unforeseen production issues, or the need for customizations. Therefore, it is advisable to contact the manufacturer directly to get an accurate estimate of the lead time for a specific steel frame formwork order.

- Q:What are the common quality control inspections for steel frame formwork installations?

- Some common quality control inspections for steel frame formwork installations include checking for proper alignment and leveling of the formwork, ensuring that all connections and fastenings are secure, inspecting the quality and condition of the steel frames, verifying the accuracy of measurements and dimensions, and conducting visual inspections for any defects or damage. Additionally, inspections may also involve checking the integrity of concrete pour and the overall stability of the formwork structure.

- Q:What are the different types of accessories available for steel frame formwork?

- There are several types of accessories available for steel frame formwork, each serving a specific purpose in the construction process. Some of the common accessories include: 1. Wedges: These are used to secure the formwork panels tightly together, ensuring a consistent and sturdy framework. 2. Clamps: Clamps are used to hold the formwork panels in place, preventing any movement during the pouring of concrete. 3. Ties: Ties are used to connect the formwork panels to the structure being built, providing additional stability and support. 4. Brackets: Brackets are used to support the formwork panels at corners or intersections, allowing for a seamless connection between different sections of the formwork. 5. Struts: Struts are used to support the formwork panels vertically, providing additional strength and stability. 6. Anchors: Anchors are used to secure the formwork to the ground or other structures, preventing any movement or displacement. 7. Release agents: Release agents are applied to the formwork to prevent the concrete from sticking to the panels, making it easier to remove the formwork once the concrete has set. 8. Formwork tape: Formwork tape is used to seal the joints between formwork panels, preventing any leakage of concrete during the pouring process. 9. Formwork oil: Formwork oil is applied to the formwork panels to provide a smooth and even surface, ensuring easy removal of the formwork once the concrete is set. 10. Formwork accessories storage: Storage systems are available to organize and store all the formwork accessories efficiently, allowing for easy access and retrieval when needed. These accessories play a crucial role in ensuring the stability, strength, and functionality of the steel frame formwork system, allowing for efficient and safe construction processes.

- Q:What are the key considerations for selecting the appropriate steel frame formwork supplier?

- When selecting the appropriate steel frame formwork supplier, there are several key considerations that should be taken into account. These considerations include: 1. Quality and durability of the formwork: It is important to choose a supplier that provides high-quality and durable steel frame formwork. The formwork should be able to withstand the pressure and weight of the concrete without deformation or failure. 2. Customization options: Different construction projects may require specific formwork dimensions and configurations. Therefore, it is crucial to choose a supplier that offers customization options to meet the specific needs of the project. 3. Efficiency and ease of use: The formwork system should be designed for easy assembly and disassembly, allowing for efficient and time-saving construction processes. It should also be user-friendly, with clear instructions and intuitive design. 4. Availability and delivery time: Timely availability of the formwork is essential to ensure smooth progress of the construction project. It is important to choose a supplier that has a reliable and efficient delivery system to ensure on-time delivery. 5. Safety features: The formwork system should have adequate safety features to protect workers during construction. This includes features such as non-slip surfaces, guardrails, and secure connection points. 6. Technical support and after-sales service: A reputable supplier should provide excellent technical support and after-sales service. This includes assistance with installation, troubleshooting, and maintenance of the formwork system. 7. Price and cost-effectiveness: While price should not be the sole determining factor, it is important to consider the overall cost-effectiveness of the formwork system. This includes factors such as longevity, reusability, and the supplier's ability to provide cost-saving solutions. 8. Reputation and track record: It is advisable to choose a supplier with a good reputation and a proven track record in providing high-quality steel frame formwork. Reading customer reviews and seeking recommendations can help in assessing a supplier's reliability and performance. By considering these key factors, construction professionals can select the appropriate steel frame formwork supplier that best suits their project requirements, ensuring a successful and efficient construction process.

- Q:How does steel frame formwork handle the pouring and curing of concrete?

- Steel frame formwork is a construction technique that uses steel frames to support and shape the pouring and curing of concrete. The steel frames are designed to be strong, rigid, and adjustable, allowing them to withstand the weight and pressure of the concrete during pouring. They provide a stable structure that ensures accurate alignment and positioning of the concrete, preventing any potential deformations or misalignments. Additionally, the steel frames are durable and reusable, making them cost-effective and efficient for multiple concrete pouring and curing processes.

- Q:Can steel frame formwork be used for multi-story buildings?

- Yes, steel frame formwork can be used for multi-story buildings. Steel frame formwork is a versatile and durable construction technique that offers several advantages for multi-story buildings. Firstly, steel frame formwork provides strength and stability to support the weight of multiple floors. It can withstand the high loads and pressures generated by the different construction stages and the weight of the building itself. This makes it suitable for constructing tall buildings with multiple stories. Secondly, steel frame formwork allows for efficient and precise construction. The modular nature of steel formwork systems enables quick assembly and disassembly, saving time and labor costs. It also allows for flexibility in adapting to different floor layouts and structural designs. Additionally, steel frame formwork provides a smooth and even finish to the concrete structure, ensuring high-quality construction. The steel panels are typically coated or treated to prevent rust and corrosion, ensuring the longevity and durability of the formwork system. Furthermore, steel frame formwork can be reused multiple times, making it a cost-effective choice for multi-story buildings. Unlike traditional timber formwork, steel formwork can be easily dismantled, cleaned, and reused for future projects, reducing waste and saving resources. In conclusion, steel frame formwork is a suitable and efficient choice for multi-story buildings. Its strength, durability, versatility, and cost-effectiveness make it an ideal construction technique for constructing tall structures with multiple floors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coupler Scaffolding Clamp Formwork Stage Lighting Scaffolding Cnbm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords