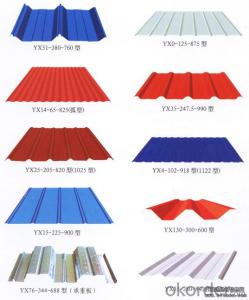

Corrugated Steel sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) AVAILABLE DESIGNATION OF (Prepainted galvanized steel coils) printed PPGI coils

Quality Q/BQB 440-2003 JIS G3312-1994 EN 10326-2004 ASTM A653-02a

EN 10327-2004 (BASE PLATE)

(BASE PLATE)

Commercial Steel TDC51D CGCC DX51D+Z/AZ CS Type A/B/C

Forming Steel (TSt01,TSt02,TSt03) CGCD1 FS Type A, Type B

Drawing TDC52D /TDC53D - DX52D+Z/AZ DDS TYPE A/C

Steel DX53D+Z/AZ

Structural TS280GD(TStE28) CGC400 S280D+Z/AZ SS275

Steel TS350GD(TStE34) CGC440 S350D+Z/AZ SS340 Class1

2) OUR SPECIFICATION OF (Prepainted galvanized steel coils) printed PPGI coils

Available Size:

Manufacturer Thickness Width Length of plate Inner diameter of coil

JIANGSU HUIYE STEEL SHEET CO.,LTD 0.2-1.2mm 800/914/1000/1200/1219/1250mm 1000-6000mm 508mm/610mm

Coated Mass OF (Prepainted galvanized steel coils) printed PPGI coils:

Base plate Available Coated Mass(g/m^2)

Galvanized Steel 80, 100, 120, 160, 180

Galvalume Steel 50, 70, 150

Available Painting OF (Prepainted galvanized steel coils) printed PPGI coils:

Category of Painting Item Code

Polyester PE

High-durability polyester HDP

Silicon modified polyesters SMP

Polyvinylidene fluoride PVDF

Easy-Cleaning —

Painting Thickness Top side: 20+5microns;

Bottom side: 5~7microns.

Color System Produce according to RAL Color System or as per buyer’s color sample.

Painting structure Top surface Bottom surface

Primer coating No coating 1/0

Primer coating Primer coating 1/1

Primer coating + Finish coating No coating 2/0

Primer coating + Finish coating Primer coating or single back coating 2/1

Primer coating + Finish coating Primer coating + Finish back coating 2/2

- Q:What are the different certification standards for steel sheets?

- There are various certification standards for steel sheets, including ISO 9001 which ensures quality management systems, ISO 14001 which focuses on environmental management systems, and ASTM A568/A568M which specifies the general requirements for steel sheet products. Additionally, there are standards such as ASTM A653/A653M for hot-dip galvanized steel sheets and ASTM A1008/A1008M for cold-rolled steel sheets. These standards help ensure the quality, performance, and compliance of steel sheets in different applications.

- Q:What is the coefficient of friction of steel sheets?

- The coefficient of friction of steel sheets can vary depending on various factors such as the type of steel, surface finish, and the materials it is in contact with. However, in general, the coefficient of friction for steel sheets is typically around 0.6 to 0.8.

- Q:What are the weight considerations for steel sheets?

- Weight considerations for steel sheets vary depending on the specific application and desired outcomes. Here are a few important points to keep in mind: 1. Thickness: The weight of a steel sheet is greatly influenced by its thickness. Thicker sheets generally have more weight, while thinner sheets are lighter. It is important to select a thickness that meets the project's structural requirements while also considering weight limitations. 2. Strength requirements: Different applications call for steel sheets with varying levels of strength. High-strength sheets are often thicker and heavier, while lower strength sheets can be thinner and lighter. Understanding the strength requirements of the project is essential in determining the appropriate weight of the steel sheets. 3. Transportation and handling: The weight of steel sheets affects how easy they are to transport and handle. Heavier sheets require more labor and equipment for lifting, loading, and unloading. Additionally, transport vehicles have weight restrictions that must be taken into account when choosing sheet sizes. 4. Structural limitations: The weight of steel sheets can impact the overall structural design. In some cases, lighter sheets may be preferred to reduce the load on supporting structures. However, in other situations, heavier sheets may be necessary to provide the required strength and stability. 5. Cost considerations: The weight of steel sheets also affects the overall project cost. Heavier sheets generally cost more due to the increased material needed and additional handling expenses. Therefore, it is important to find a balance between weight, cost, and performance to optimize the project budget. In conclusion, weight considerations play a crucial role in determining the appropriate thickness, strength, transportation requirements, structural design, and cost-effectiveness of steel sheets for a project. By carefully evaluating these factors, one can select steel sheets that meet specific needs while ensuring the optimal weight for the desired outcome.

- Q:Q235 is hot rolled steel or cold rolled steel?

- Hot rolling and cold drawing is the difference of the production process of hot rolling is processed at high temperature, does not change the structure and properties of metal at high temperature, cold drawn round will be perforated, then in tube processing machine in the cold drawing, no tempering condition, this process will affect the crystal structure of metals. In general, better than the mechanical properties of cold rolled steel, after heat treatment, the tensile and yield strength, plasticity and toughness will be improved, in addition, heat treatment can eliminate the residual stress, and the cold may be because in the process of the steel yield the non-uniform deformation. The residual stress produced, the residual stress has great influence on the stability of.

- Q:What is the difference between a satin and mirror finish steel sheet?

- The main difference between a satin and mirror finish steel sheet lies in their appearance. A satin finish has a smooth, brushed texture with a muted sheen, while a mirror finish has a highly reflective, glossy surface that resembles a mirror. The satin finish is achieved through a process of sanding or brushing the steel, creating fine lines or grain, whereas a mirror finish requires additional polishing and buffing to achieve its reflective quality.

- Q:What are the different surface treatments for galvanized steel sheets?

- There are several surface treatments available for galvanized steel sheets, including chromate conversion coating, painting, powder coating, and zinc phosphate coating. These treatments are used to enhance the corrosion resistance, improve the aesthetic appearance, and provide additional protection to the steel surface.

- Q:What is the process of etching or engraving on steel sheets?

- The process of etching or engraving on steel sheets involves using various techniques to create designs or patterns on the surface of the steel. Typically, a design is either etched or engraved onto a protective coating applied on the steel sheet using chemicals, tools, or lasers. The protective coating is then removed, revealing the etched or engraved design on the steel surface. This process is commonly used in industries such as manufacturing, jewelry making, and metal art.

- Q:Are steel sheets suitable for manufacturing water pipes?

- Indeed, water pipes can be manufactured using steel sheets. Steel, being both durable and strong, possesses the ability to endure high pressure and corrosion, rendering it an optimal selection for water pipes. By skillfully molding and welding steel sheets, one can effortlessly produce seamless pipes that are impervious to leaks. Furthermore, steel pipes boast a lengthy lifespan and demand minimal upkeep, establishing themselves as an economically viable choice for water pipe production.

- Q:Can steel sheets be used for medical equipment?

- Yes, steel sheets can be used for certain medical equipment. Surgical instruments, hospital beds, and imaging equipment often contain steel components or have steel sheets as part of their construction. However, the suitability of steel sheets for specific medical equipment may depend on factors such as the desired strength, corrosion resistance, and regulatory requirements.

- Q:Can steel sheets be used for signage purposes?

- Indeed, signage purposes can be served by steel sheets. Their durability allows them to withstand harsh weather conditions, rendering them appropriate for outdoor signage. Various sizes and designs can be achieved by cutting, shaping, and welding the steel sheets, offering versatility in crafting personalized signage. To enhance aesthetics and ensure long-lasting quality, the steel sheets can be painted or coated with different finishes. Moreover, their sturdiness enables secure mounting, making them an excellent choice for large and heavy signage installations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corrugated Steel sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords