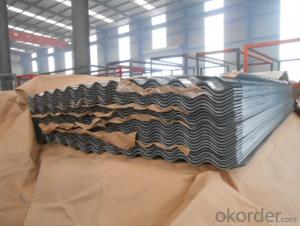

Corrugated Hot -Dip Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corrugated Hot Dipped Galvanized Steel Sheet

Description:

The corrugated sheet is a high strength and durable steel, mostly used for a architectural decoration. We have scores of corrugated sheets production lines of different types, producing profiled sheets of all kinds of types and colors. Since it adopts high strength steel sheet and the dimension is designed reasonably, the corrugated sheets are widely used on roofs and walls of various buildings, which can be easily installed, be flexible and changeable, unrestricted by no factor of the buildings.

Corrugated steel sheet is the colored steel plate which has been wave formed with the cold rolling treatment, trough especial coated dispose, the color coated steel panel’s guaranty is 12-15 years.

Application:

It has been widely applied on civil construction like storerooms, special building roof and walls of wide-span steel structure building and so on.

With excellent cold bending molded manufacturability, good decoration effect, strong anti-corrosion ability, are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration

Pressing steel panel with the clear line, and many colors for choice, suitable for any different building style materials, achieving satisfy effects;

Product Specification:

Thickness tolerance: (+/-0.01mm)

Zinc coating: 50-180g/m2

Standard:jis g 3302, sgch

Package: 2- 3 ton/pallet

Specs: 0.14-0.8mm x 900mm x 2000mm

Width:700-1250mm( 750mm,900mm,1215mm,1250mm,1000mm the most common)

Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel ,sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one package?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. Could you produce the sheets according to our design?

Yes, we can.

- Q:What are the environmental impacts associated with steel sheet production?

- The environmental impacts associated with steel sheet production include the extraction and processing of raw materials, such as iron ore and coal, which contribute to deforestation, habitat destruction, and air and water pollution. The production process also emits greenhouse gases, including carbon dioxide and methane, contributing to climate change. Additionally, the disposal of waste materials generated during production can contaminate soil and water sources.

- Q:Are steel sheets available in different hardness levels?

- Yes, steel sheets are available in different hardness levels. The hardness of a steel sheet is determined by factors such as the composition of the steel, the heat treatment it undergoes, and any additional processing or alloying. Steel sheets can range from very soft and malleable to extremely hard and durable. The most commonly used hardness scale for steel sheets is the Rockwell scale, which measures the indentation hardness of the material. By offering different hardness levels, steel sheets can meet a wide range of application requirements, from forming and bending to high-wear applications that require excellent resistance to abrasion.

- Q:Can steel sheets be used in packaging applications?

- Yes, steel sheets can be used in packaging applications. They are commonly used for packaging heavy or fragile items that require extra strength and protection. Steel sheets provide durability, rigidity, and resistance to impact, making them suitable for various packaging needs in industries such as automotive, construction, and industrial manufacturing.

- Q:What is the difference between a satin and mirror finish steel sheet?

- The appearance and level of reflectivity distinguish a satin finish steel sheet from a mirror finish steel sheet. A satin finish steel sheet displays a sleek, non-glossy appearance with a minimal level of reflectivity. Achieved through the use of abrasive materials, it creates a brushed or textured surface. This finish is often favored for its contemporary and subtle aesthetic. Satin finish steel sheets find common usage in architectural and interior design applications, such as kitchen appliances, countertops, and wall panels. On the contrary, a mirror finish steel sheet exhibits an immensely reflective surface that closely resembles a mirror. Achieved by polishing the steel sheet to a high gloss using fine abrasives and buffing compounds, this finish boasts an intense shine and exceptional clarity. It reflects light remarkably, resulting in a glamorous and opulent appearance. Mirror finish steel sheets are commonly employed in decorative applications, including automotive trim, jewelry, and ornamental architectural elements. To summarize, the primary distinction between a satin and mirror finish steel sheet resides in their appearance and level of reflectivity. Satin finish offers a smooth, matte appearance with minimal reflectivity, while mirror finish provides an incredibly reflective, mirror-like surface.

- Q:Are steel sheets suitable for construction scaffolding?

- Yes, steel sheets are suitable for construction scaffolding. Steel is a strong and durable material that can provide the necessary support and stability required for scaffolding systems. It can withstand heavy loads and provide a secure platform for workers to perform their tasks safely. Additionally, steel sheets can be easily assembled, disassembled, and reused, making them a cost-effective choice for construction scaffolding.

- Q:Can steel sheets be used for mezzanine flooring?

- Indeed, mezzanine flooring can make use of steel sheets. Mezzanine flooring benefits from the numerous advantages provided by steel sheets, such as their strength, durability, and versatility. Steel sheets are capable of withstanding substantial loads and offer a dependable and stable solution for flooring needs. Moreover, they can be easily tailored to suit specific dimensions and requirements, making them adaptable for various mezzanine designs. Additionally, steel sheets exhibit resistance to fire, moisture, and pests, guaranteeing a flooring option that is long-lasting and requires minimal maintenance. In summary, due to their robustness, durability, and adaptability, steel sheets are a popular choice for mezzanine flooring.

- Q:What is the difference between a galvanized and painted steel sheet?

- A galvanized steel sheet is coated with a layer of zinc, which provides protection against corrosion. On the other hand, a painted steel sheet is coated with a layer of paint, which provides aesthetic appeal and protection against weathering.

- Q:What is the difference between hot dipped galvanized and electro galvanized steel sheets?

- Hot dipped galvanized and electro galvanized steel sheets are both types of galvanized steel, but they differ in the method of application and the resulting characteristics of the coating. Hot dipped galvanized steel sheets are made by immersing the steel into a molten zinc bath. This process creates a thick, durable coating that provides excellent corrosion protection. The steel is completely coated in zinc, both on the surface and on the edges, ensuring complete coverage and protection against rust and other forms of degradation. The coating thickness can vary depending on the application and the required level of protection. On the other hand, electro galvanized steel sheets are produced by electroplating steel with a thin layer of zinc. The steel is first cleaned and treated with an acid solution to remove impurities and improve adhesion. Then, it is immersed in a zinc electrolyte solution, and an electric current is passed through the bath, causing the zinc ions to bond with the steel surface. This process results in a much thinner coating compared to hot dipped galvanized steel. Due to the thinner coating, electro galvanized steel sheets provide less corrosion protection than hot dipped galvanized steel sheets. They are more suitable for indoor applications or environments with less exposure to harsh conditions. However, electro galvanized steel sheets offer other advantages such as a smoother and more uniform appearance, making them popular for applications where aesthetics are important, such as automotive parts or appliances. In summary, the main difference between hot dipped galvanized and electro galvanized steel sheets lies in the method of application and the resulting coating thickness. Hot dipped galvanized steel sheets have a thicker, more durable coating, providing superior corrosion protection, while electro galvanized steel sheets have a thinner coating, making them more suitable for indoor applications and offering a smoother appearance.

- Q:What is the thickness of the water resisting steel plate of the electrical outlet?

- According to the standard atlas "waterproof sleeve 02S404", the thickness of the water stopping ring steel plate should be 10mm~14mm.

- Q:Are steel sheets resistant to vibration or shaking?

- Yes, steel sheets are resistant to vibration or shaking due to their strong and rigid nature.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corrugated Hot -Dip Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords