corrugated colored steel sheets 2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | Grade: | Thickness: | |||

| Place of Origin: | Brand Name: | Type: | |||

| Technique: | Surface Treatment: | Application: | |||

| Special Use: | Width: | Length: | |||

| color: |

Packaging & Delivery

| Packaging Detail: | corrugated color steel sheet /stainless color steel sheet seaworthy package with wooden pallet |

| Delivery Detail: | 20 days after receiving deposit |

Specifications

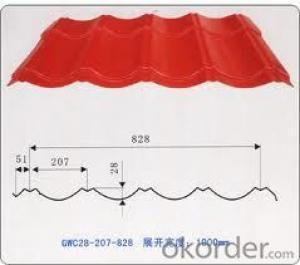

corrugated color steel sheet /stainless color steel sheet

1.Prime Quality,Low Price, Efficient Delivery.

2.Free sample.

corrugated color steel sheet /stainless color steel sheet

1. Base material: hot dipped galvanized steel

2. Width: available from 914MM to 1250MM

3. Width Tolerance: within 0.02MM

4. Thickness: available from 0.20MM to 0.80MM

5. Thickness Tolerance: within 0.15MM

6. Performance: Matte or GLossy

7. Color: according to RAL standard

8. Lacquer Coating thickness: according to customer needs

9. Supply capacity: 7000 Metric Ton per month

Our products has good performance on combining force and anti-erosion. We offer fine quality products and best price for our international customers. PPGI is light, beautiful and has good corrosion resistant performance, can be directly processed also, ppgi provides the construction, shipbuilding, vehicle manufacturing, furniture industry, and electrical industry a new material, while ppgi has good effects on the areas of replacing wood with steel, efficient construction, energy saving, prevent pollution etc.

Advantages of Our Prepainted Galvanized Steel Coil:

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Applications of Prepainted Galvanized Steel Coil:

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

Coating Chief Feature

| Project | Pencil hardness | Reverse impact | T bending | Cupping test | MEK cleaning |

| Front/back | ≥ H/2H | ≥ 9J/6J | ≤ 3T/5T | ≥ 6mm/4mm | ≥ 100time/50time |

Structure of GI/PPGI

| Item | Thickness | Type | Feature |

| Laminated film | 50μm | Polyethylene | Protecting from scratchs and contamination (option) |

| Top coat | 20μm | Polyester Fluorine | Chemical resistance and formability |

Primer coat | 5μm | Polyester | Workability, corrosion resistance and adhesion to the primer coating |

| Chemical treatment | 1μm | Chromate | Good adhesion and corrosion resistance |

| Substrate | 0.2mm-1.2mm | GI.GL,AL | GI.GL,AL |

| Back coat |

5±2μm |

Epoxy | Corrosion resistance and adhesion to the substrate |

- Q:What are the disadvantages of using steel sheets?

- One of the main disadvantages of using steel sheets is their susceptibility to corrosion. Steel is prone to rusting when exposed to moisture or certain chemicals, which can compromise its structural integrity over time. Additionally, steel sheets are relatively heavy and can be challenging to handle and transport compared to other materials. Moreover, steel sheets require proper insulation to prevent condensation and thermal bridging issues. Lastly, steel sheets are subject to price volatility as the cost of steel can fluctuate significantly in response to market conditions.

- Q:What are the limitations of using steel sheets?

- There are several limitations associated with using steel sheets in various applications. Firstly, steel sheets are relatively heavy compared to other materials, which can pose challenges in terms of transportation and installation. This weight can also limit their use in applications where weight reduction is critical, such as aerospace or automotive industries. Secondly, steel sheets are susceptible to corrosion, especially when exposed to moisture and chemicals. If not properly protected, this can lead to rusting and a decrease in structural integrity over time. Therefore, additional coatings or treatments are often required to prevent corrosion, adding to the overall cost and maintenance requirements of steel sheet usage. Another limitation is that steel sheets have limited flexibility and cannot be easily molded or shaped into complex forms. This restricts their use in applications where intricate designs or curved surfaces are required, such as in the construction of curved roofs or architectural structures. Furthermore, steel sheets have poor thermal insulation properties, meaning they conduct heat and cold more readily than other materials. This can result in temperature fluctuations and energy loss in buildings, requiring additional insulation measures to maintain thermal comfort and energy efficiency. Lastly, steel sheets are a finite resource and their production can have a significant environmental impact. The extraction of raw materials, energy consumption, and carbon emissions associated with steel production make it less sustainable compared to alternative materials. In summary, while steel sheets are widely used for their strength and durability, their limitations include their weight, susceptibility to corrosion, limited flexibility, poor thermal insulation properties, and environmental impact. These limitations should be considered when selecting materials for specific applications.

- Q:What are the load-bearing capacities of steel sheets?

- The load-bearing capacities of steel sheets vary depending on their size, thickness, and grade. Generally, steel sheets can bear significant loads due to their high strength and durability. However, it is important to consult engineering specifications or consult with a structural engineer to determine the specific load-bearing capacity of a particular steel sheet.

- Q:How do steel sheets perform in low-temperature environments?

- Steel sheets generally perform well in low-temperature environments. The mechanical properties of steel, such as strength and toughness, are not significantly affected by low temperatures. Steel has a low coefficient of thermal expansion, which means it does not contract or expand drastically when subjected to temperature variations. This property allows steel sheets to maintain their shape and structural integrity in cold conditions. Moreover, steel is also highly resistant to brittle fracture at low temperatures. It has a good impact resistance, meaning it can absorb energy without fracturing. This makes steel sheets suitable for applications in low-temperature environments where materials need to withstand heavy loads or sudden impacts, such as in cold storage facilities or offshore structures in Arctic regions. However, it is worth noting that some types of steel, particularly those with high carbon content or low alloy steels, can exhibit reduced toughness and ductility at extremely low temperatures. In such cases, special precautions may be necessary, such as using steel grades specifically designed for low-temperature applications or implementing proper insulation measures to prevent rapid temperature changes. Overall, steel sheets are generally reliable and perform well in low-temperature environments due to their strength, toughness, and resistance to brittle fracture. However, the specific performance of steel in cold conditions may vary depending on the composition and quality of the steel used.

- Q:Are the steel sheets suitable for outdoor applications?

- Yes, steel sheets are suitable for outdoor applications due to their durability, resistance to harsh weather conditions, and ability to withstand corrosion.

- Q:What are the different grades of steel sheets?

- There are several different grades of steel sheets, including low carbon steel, high carbon steel, stainless steel, galvanized steel, and alloy steel. Each grade has unique properties and is used for specific applications based on its strength, durability, corrosion resistance, and other factors.

- Q:Can the steel sheets be easily painted or coated?

- Yes, steel sheets can be easily painted or coated. The smooth surface of steel sheets allows for excellent adhesion of paint or other coatings. Prior to painting or coating, it is important to clean the surface thoroughly to remove any dirt, grease, or rust that may affect the adhesion. Additionally, applying a primer or a base coat can further enhance the durability and longevity of the paint or coating. Overall, steel sheets provide a suitable and easily paintable surface for a variety of applications.

- Q:How do steel sheets compare to aluminum sheets in terms of strength?

- Steel sheets are generally stronger than aluminum sheets. Steel is known for its high tensile strength, which means it can withstand greater forces before deforming or breaking. On the other hand, aluminum sheets have lower tensile strength and are more prone to bending or warping under heavy loads. However, it is important to note that aluminum sheets can still be strong enough for many applications, especially when considering their lower density compared to steel. Additionally, aluminum sheets have the advantage of being more lightweight, corrosion-resistant, and having better thermal conductivity than steel sheets. Therefore, the choice between steel and aluminum sheets depends on the specific requirements of the project, considering factors such as strength, weight, corrosion resistance, and thermal properties.

- Q:What is the typical coefficient of thermal expansion of a steel sheet?

- The typical coefficient of thermal expansion of a steel sheet is around 10.8 x 10^-6 per degree Celsius.

- Q:Are steel sheets suitable for data center infrastructure?

- Yes, steel sheets are suitable for data center infrastructure. Steel is a strong and durable material that can provide the necessary structural integrity and support for data center equipment and systems. It is commonly used for server racks, cabinets, enclosures, and other components within data centers. Steel sheets offer stability, protection, and easy customization options, making them a reliable choice for data center infrastructure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

corrugated colored steel sheets 2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords