Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

MOQ of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality: 5000 Square Meters

Supply Ability of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality 6000000 Square Meters per Month

Payment Terms of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality: L/C,T/T

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Specifications of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Place of Origin: China (Mainland)

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Brand Name: CMAX

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Application: Wall Materials

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Width: 1M-2M

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Size: 6*6/ INCH

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Weight: 40gsm to 200gsm

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Weave Type: Plain Woven

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Yarn Type: C-Glass

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Alkali Content: Medium

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Standing Temperature: 500℃

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Product information of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Name: Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Use best fiberglass yarn and best glue

Clear and beautiful Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

High strength Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

30 years experience of manufacturing Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Excellent Priced

FAQ of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Q: What is Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

Coated Alkali-resistant Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

Weight: 90-160g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

PVC corner Bead using

Q: What is the storage of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

Four years under normal weather conditions and use .

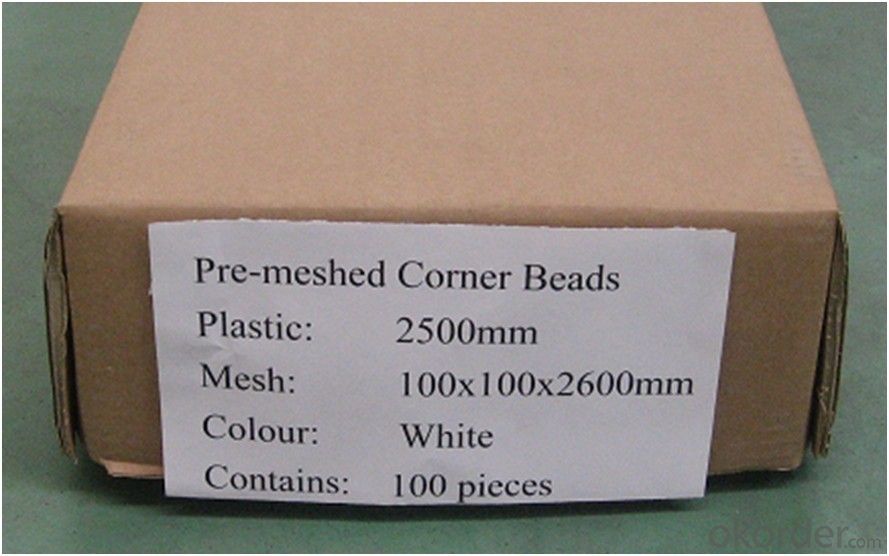

Q: What is the package of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

Production periods: 30days for 1X40HQ.

- Q:What is the difference between medium alkali glass fiber cloth and alkali resistant glass fiber cloth?

- Mainly refers to the glass composition is different,"Base" refers to a certain amount of alkali metal oxide, Na2O, commonly known as C glass fiber, which corresponds to alkali free (E) glass fiber;

- Q:Mesh cloth and Dacron cloth, which one is better?

- 1, Mesh cloth is better. 2, Mesh is not necessary. Only if there are many cracks on the wall, mesh cloths will be accessible; if the cracks are acceptable, bandage can be used to cover them. 3, when paste mesh or use bandage, the binder used must be white latex, and of high quality. 4, Putty, for filling the joints in wall treatment, can be made by gypsum powder mixing with glue, or we can just use finished products to fill putty. When level a wall, we can use talcum?powder, heavy calcium carbonate powder(whiting powder) with addition to glue, and stirred into putty, or finished putty is available, but white latex is needed in the finished putty to increase adhesion of putty. 5, Water-proof putty is used only on the walls which are disturbed by moisture, like the metope of toilet door, not with other parts. Of course, relying on water proof putty completely would be better than ordinary putty, but the cost has increased enormously.

- Q:What role does exterior wall thermal insulation mesh cloth play?

- The product has the advantages of stable structure, high strength, good alkali resistance, corrosion resistance, crack resistance, etc., and the enhancement effect is the best, and the construction is simple and easy to do.

- Q:Specifications of alkali resistant glass fiber gridding cloth

- Refer to the requirements of JG149JG158

- Q:What's the difference between window screens and window screens?

- Screen window is made of chemical fiber as raw material. It's a very thin cloth. Usually with curtain cloth matching. A cloth. Ply yarn. A gauze screen that sticks over a door and window to become a window screen; a screen is widely used in doors and windows and corridors to prevent small insects from disturbing the net. Mostly made of nylon, common white, green and blue. Sometimes also called screen window. The main role is "anti mosquito screen window". Now the screen window is more than before, more patterns, invisible screen window and removable screen window, no longer as hard as before the window will be removed and removed.

- Q:Does alkali resistant glass fiber gridding cloth belong to energy-saving material?

- Alkali resistant glass fiber gridding cloth does not belong to the energy saving materials, it is just a supplementary material used in exterior wall thermal insulation engineering used for crack resistance and increasing the strength of mortar layer.

- Q:A brief introduction to glass cloth of glass fiber cloth

- The other quality requirements are as follows: the fabric selvedge uniform, flat, smooth cloth is sheetlike, no stains, fluff, creases and wrinkles; the warp and weft density, weight, width and length are consistent with the standard; the paper core winding in solid, winding the resin fast in order; good permeability; the fabric made of laminated material of dry, wet mechanical strength shall meet the requirements.The paving composites are characterized by low interlaminar shear strength, poor compressive strength and fatigue strength. (1) chopped strand glass raw silk (sometimes with roving) cut into 50mm long, but it will be randomly evenly Chen on the mesh belt, then put on powder or emulsion binder spreading agent bonded into CSM by heating after curing. Short cut felt is mainly used for hand finishing, continuous plate making and die pressing and SMC process. The quality of CSM requirements are as follows: uniformly along the width direction of the quality area; the chopped strand mat surface in uniform distribution, no hole formation, binder distribution; with moderate strength, excellent dry mat; resin infiltration and permeability.

- Q:Does wall treatment need mesh?

- It depends on the specific quality of the original wall base. If there is no cracks or empty drum, it is usually unnecessary.

- Q:Does it is required to paste mesh in which has ben pasted with wallpaper?

- Otherwise, the later wall cracks will also affect the wallpaper. Now, the walls has been re-covered with cement. Intend to shovel all red bricks and then cover cement.

- Q:How to distinguish warp?and?weft of alkali-resistant fiberglass mesh?

- The two strands of small wire is warp, and the thicker one is weft. While being used, take warp as a horizontal position.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords