Copper Mylar Shielding Foil for Cable Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Copper Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Copper Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Copper Mylar foil Shielding Foil:

Copper Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

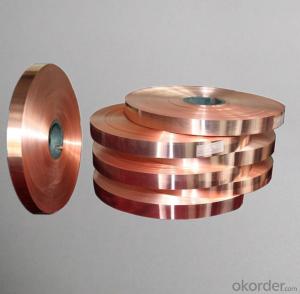

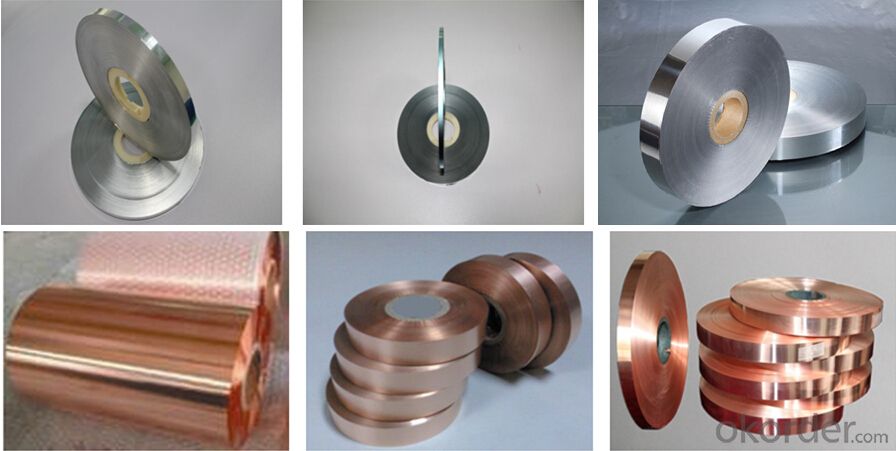

3. Copper Mylar foil Shielding Foil Images

4. Copper Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:Outdoor camping in East China, with only one foil damp barrier in the tent, plus sleeping bags? Do you need inflatable mats?

- Aluminum foil are called moisture-proof pad is completely unscrupulous businessmen gimmick. Sit still, sleep really uncomfortable, from warmth and moisture, almost ignored. If you are in a tight position, buy PURELAND's hexagonal foam mat, and if you have plenty of it, buy it yourself. Must not take the body to make fun of, the aluminum foil pad, when I just started playing, all is used to make the ground mat, at that time loves the tent, but absolutely does not have the moistureproof effect.

- Q:How can I clean the aluminum foil products when they are punched out?

- Quenching oil cold? The same oil, ah, the supply of this quenching cooling oil companies generally sell their corresponding cleaning agent. Just pay attention to the influence of cleaning agent on aluminum products.

- Q:Some drugs are packed on aluminum foil. What's the use of an empty plastic cover?

- Used to seal medicines to prevent contamination, dampness, etc

- Q:The action of perforating aluminium foil and non perforating aluminium foil

- There is no such thing as "cold" in the world. What you call "cold transmission"?",

- Q:In case a bright paper is aluminum foil or foil with what method can distinguish and what contain aluminum foil

- Because tin costs a lot, no one actually does itThe difference between foil foil or method can be used for burning, two different melting point, the low melting point of tin.

- Q:Why aluminum foil can escape metal detector?

- The principle of metal detector is ultrasonic inspectionThe ultrasonic wave refracted through the metal,

- Q:How to wrap foil briquettes fire chimney?

- Do you have bags for chimneys? First, the chimney material, either galvanized iron sheet, or brick, these are fire resistant, resistant to burning;

- Q:How to calculate the aluminum foil material?How can we calculate the number of meters with weight, length and thickness?

- The weight depends on the length, width, density, thickness of the foil. If there is a composite film, the density of the plastic film and the density of the glue will also need to be known

- Q:What is a composite aluminum foil molded poly vinyl foam board, and what is a composite aluminum foil extrusion poly vinyl vinyl insulation board, the two how to distinguish?Please try to be more specific

- 3, water absorption rate EPS, water absorption rate is higher than XPS, XPS almost no water absorption4, the strength of EPS, 80~100KPA, XPS, 150~1000KPA, used in the wind pipe 150~250 can5, flame retardant properties of EPSXPS can reach B1 B26, the price of EPS is lower than XPSConclusion, if used in air conditioning, air duct and so on, XPS is superior in performance analysis,

- Q:I heard that using aluminum foil and salt to add water can make the silver ring bright. Who told me what aluminum foil is and where can I buy it?

- Aluminum foil in the construction of the application is quite obvious, paste on the surface of thermal insulation material, make it more convenient and clean construction, especially the aesthetic degree to a new height. But the effect of different kinds of foil is very different, for example, fire and ordinary are not a grade.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Copper Mylar Shielding Foil for Cable Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords