Copper Mylar Foil Shielding Foil for Cable Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Copper Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Copper Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Copper Mylar foil Shielding Foil:

Copper Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

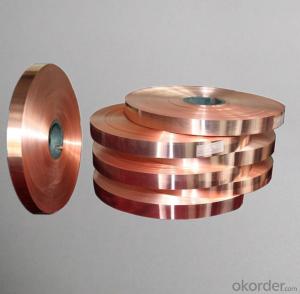

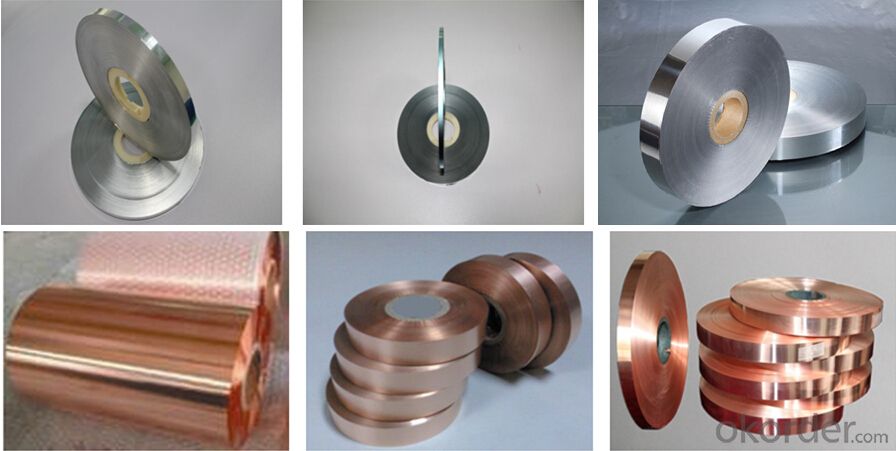

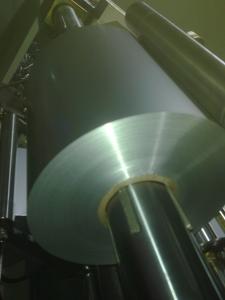

3. Copper Mylar foil Shielding Foil Images

4. Copper Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:How do you microwave the chicken wings with aluminum foil?

- If you want to use the microwave oven barbecue, mini baking sheet, please use the light wave heating (remember). Aluminum foil is used to wrap the barbecue items. Grilled chicken wings, wrapped with aluminum foil to prevent live chicken wings, barbecue when oil splash, cause it is difficult to clean the microwave oven, and can prevent the scorched wings.

- Q:How to use aseptic packaging aluminum foil bag?

- Foil bag has many advantages over other traditional packaging materials (such as difficult to have superior performance, molding, convenient use, low cost, etc.) as one of the plastic packaging materials, which plays a great role in the development of aluminum foil bag, along with other traditional packaging materials incomparable speed. It has been widely used because of its various shapes and different performances. This is the main characteristic of plastic packing. It can be the ideal performance of various uniform reasonably, such as transparency, thermal stability, physical strength, biological isolation and sealing, radiation resistance, processing and commodity, publicity, protection, use of organically. Together. Make aluminum foil bags as food, beverages, pharmaceuticals and pharmaceutical equipment and other materials, one of the best packaging products, especially in its sealing properties, but also make these products have been well protected and promoted. Although plastic bags of ten rich content, in different poses and with different expressions, but the two most basic forms: one is nothing more than open the packing bag use: such as shopping bags, R bags, Ma Jiadai, hand bags, garbage bags, rope bags, food bags and other packaging bag; seal: such as three edges two side sealing, sealing, sealing the ordinary bags, composite bags and cooking bags etc..

- Q:How can I clean the aluminum foil products when they are punched out?

- There are many kinds of drawing oils, and there are usually special cleaning agents. You can specifically ask your drawing oil supplier, according to the oil purchase.

- Q:The aluminum foil is induced by a magnetic field. Why does it produce the opposite magnetic field?

- This series produced with iron nails, and the contact end is opposite to the magnetic field magnet. The electromagnetic furnace caused by the magnetic field, and the relationship between the magnet nails, so the electromagnetic oven is opposite to the magnetic induction. If it were similar to an electromagnet, the foil would have the same magnetic field

- Q:With foil and foil barbecue which is better?

- Because many seasonings will add some juice, citric acid or acetic acid, but whether it is vinegar (vinegar or vinegar), are acidic substances, if contact with tinfoil or aluminum foil under high temperature metal release, so that the metal content of food rose. Lin Jieliang believes that the single use of tin foil or aluminum foil, separated by high temperature charcoal, can prevent food from burning caused by carcinogens, is more healthy food, but do not recommend adding seasonings containing acidic substances

- Q:The foil can be used in the microwave heating?

- The electric field of thick metal can resist the microwave, and the microwave reflected out, so the inner wall of the microwave oven is made of thick metal; if the thick walled metal container in the microwave and metal containers will reflect the microwave so that the food is not heated. But the foil is too thin, so electrical conductivity can cause a catastrophic reaction. The process of conducting a thin metal so rapidly that its temperature rises linearly can cause a fire. At the same time, the tip produced by the heat contraction of the foil causes sparks, which can ignite any combustible material in the microwave oven.

- Q:The difference between aluminum foil and aluminum foilThe performance of these two products, hygiene, price difference

- And now the rise of the price is aluminum foil, foil cheap, most of the packaging is aluminum foil.How many a little tin containing lead, from food hygiene, than foil. Aluminum foil

- Q:Car sunshade and black aluminum foil which is good, and the aluminum foil is white or cartoon, mainly considering the shading effect

- The car shade is made of aluminum foil. The best color is white, the effect is good, if you like the cartoon, choose light color.Aluminum foil in general, general "light plate" type and pattern type, size is generally 60*130cm, suitable for most small cars. The aluminum foil heat shield with suction cup is easy to use. After expansion, it can be sucked in front windshield or inside rear window by suction cup.

- Q:What is a composite aluminum foil molded poly vinyl foam board, and what is a composite aluminum foil extrusion poly vinyl vinyl insulation board, the two how to distinguish?Please try to be more specific

- 3, water absorption rate EPS, water absorption rate is higher than XPS, XPS almost no water absorption4, the strength of EPS, 80~100KPA, XPS, 150~1000KPA, used in the wind pipe 150~250 can5, flame retardant properties of EPSXPS can reach B1 B26, the price of EPS is lower than XPSConclusion, if used in air conditioning, air duct and so on, XPS is superior in performance analysis,

- Q:What's the use of aluminum foil?

- Aluminium foil for electrolytic capacitorElectrolytic capacitor with aluminum foil is a kind of work in polar conditions of corrosive materials, structure of aluminum foil have higher requirements, the aluminum foil is divided into three types: the cathode foil thickness is 0.015mm ~ 0.06mm; high pressure foil thickness is 0.065mm ~ 0.1mm, with the requirements of production of high purity aluminum foil; low pressure foil thickness is 0.06mm ~ 0.1mm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Copper Mylar Foil Shielding Foil for Cable Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords