Converter Tap Hole Stopping-Slag Slide Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Converter Tap Hole Stopping-Slag Slide Plate

Pure zirconia plate is inlayed in the important region of converter tap hole stopping-slag slide plate. The matrix is made of stable medium and high temperature AZC materials,which has long service life, excellent effects of stopping-slag.

Medium or high temperature sintered Sialon bonded sliding gate at N2 atmosphere

Independent research and development of new sliding gate by importing special sialon additives, sintering at the medium our high temperature of N2 atmosphere. In the process of sintering create the sialon phase with good medium or high temperature performance, thus improved the high temperature compression strength and the breaking strength. The using effect on the large and medium-sized steel ladle and the tundish is good.

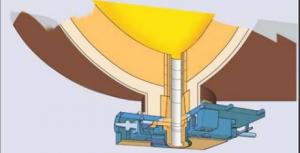

BOF taphole slag slide gate mechanism

Using the mechanism of BOF slag could recovery slag effectively in the furnace. And slag splashing protection technology could increase converter furnace which can solve the problem of irregular erosion in taphole. By the new process of slag controlled tapping , can improve the alloy yield, and can also greatly save the amount of aluminum addiction, the comprehensive cost reduction is considerable, and it also improved the economic efficiency and the competitiveness of the products in the market, it’s the first choice of equipment for smelting high quality steel.

- Q:How is the fire endurance of the fireproof paint?

- time is different according to the amount of fireproof paint used. fire resistance time :0.5 hours 1.5 hours 2.0 hours 2.5 hours thickness: 0.45mm 0.9 mm 1.4 mm 2.0 mm 2.8 mm Amount: 0.79kg / m2 1.5 kg / m2 2.3 kg / m2 3.3 kg / m2 4.6 kg / m2

- Q:Which industry does refractory belong to?

- It belongs to construction industry.

- Q:What are the meanings of azs, 34% and ec in fused brick?

- The fused brick, also called zircon corundum brick, is shorted as AZS for three chemical components in Al2O3-ZrO2-SiO2 ternary diagram. I don't know the meaning of EC.

- Q:What are the insulation fireproofing materials?

- Insulated shoes, insulated gloves, tape (cloth, plastic, as well as waterproof) yellow wax tube, mouth care, fireproof (ie asbestos cloth is sold by jin) there is pressure-caps black tape, waterproof tape ,casing. There are glass fiber needle felt is widely used in electrical, chemical, construction, transportation, automotive and other industries interlayer insulation and silencer system, and used as an insulating fireproof material.

- Q:Which one is the best refractory material?

- Resin bonded refractory is mainly abot aluminum magnesium carbon, and carbonaceous etc. Thermoplastic resins need to add the coagulant (Uto), ageing mixture for a period of time, so the production cycle is long. Hot hard resin is relatively not so complex, but it’s not as good as thermoplastic resins in thermoplastic binding.

- Q:Development trend of refractories

- Facing the survival and development of refractory industry challenges in many aspects, serious: 1, the user industry due to the progress of science and Technology (such as iron, iron and steel industry in the direct reduction furnace, to reduce casting, slag splashing etc.), reduce refractory material consumption; 2, refractory material environmental protection and ecological requirements; 3, users of the product quality and cost requirements; 4, users risk transfer, refractory material, the design requirements of the liner construction, maintenance services, and even provide construction equipment; 5, between refractory enterprises and personnel dispute price; 6, due to the industry downturn in some countries, the decline in refractory material and the lack of education, lack of young professionals; 7, resource depletion and other raw materials.

- Q:What is the function of refractory material?

- Refractory is a basic material in the field of high temperature technology. Generally, the refractory is used as structural material or lining to resist high temperature in various thermal equipment and high temperature container. In the iron and steel industry and metallurgy industry, coke ovens are mainly composed of refractory materials. Various refractories that meet the requirements are essential in blast furnace for ironmaking, hot stove, all kinds of steel-making furnaces, soaking furnace and heating furnace. Not only the die casting for molten steel needs lots of refractory materials, but also the continuous casting needs some high-quality refractory materials. Without high-quality refractory materials, external refining is also not impossible to achieve. Statistics show that the steel industry is the sector that needs the most refractory. Pyrometallurgy and thermal processing of ferrous metal also needs refractories. All high-temperature furnaces or lining in construction materials industry or other high temperature industries that produce silicate products such as glass industry, cement industry, and ceramics industry must be constructed with refractory materials. All kinds of roasting funaces, sintering funaces, heating furnaces, boilers, flues, chimneys and protective layers in chemical, power and machinery manufacturing industry need refractories. In short, when some kind of structures, devices, equipments or vessels are used under high temperature, they all should utilize refractory to resist the high temperature because those materials will deform, soften and fuse or will be eroded, scoured or broken due to the physical, chemical, mechanical effects, which may stop the operation, affect the production, contaminate processed objects and impact the quality of products.

- Q:How many kinds of refractory materials are there in the EI?

- I suggest that you contribute articles to foreign SCI journals for the odds are better, and generally the articles that fill the bill will not be rejected. The traditional refractory materials can contribute to EI journal. If being rejected by EI journal, you can also contribute to Russia's journal Industrial Ceramics and Refractories. I didn't contribute to the Journal of Wuhan University of Science and Technology, the receiving cycle is almost 3 to 4 months. Though the impact factor is low, domestic EI journal is not so good, it is still SCI journal. This is my own experience, please take my advice. The best journals are the Journal of the American Ceramic Society and the Journal of the European Ceramic Society, I heard that they are not bad. But the best domestic EI refractory material journal is the Journal of The Chinese Ceramic Society. It is very long, but if it belongs to your university, it is another pair of shoes. Journals now all want to have materials about functional ceramics, and they don't want Chinese articles, if your English is not well enough, you can choose Ceramics International and Japan Ceramics but they have strict manuscripts reviewing standards.

- Q:How is the grading of the level A new material fire insulation material?

- The thermal insulation materials are generally divided into level A and level B according to the flame rating. Level A is the non-combustible material, and level B is the combustible materials. The level B material is to blame for the fire in Shenyang hotel in CCTV building a few years ago . At present, the level A materials are widely used, with some prices even cheaper than the level B material. A level is roughly divided into insulation mortar, phenolic board, rock wool board and foam cement board, ect.

- Q:what is best for making refractory insulation for Blast furnace, hot stove.

- High dimensional insulating blanket.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Converter Tap Hole Stopping-Slag Slide Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords