Continuous Casting Mill Finished Aluminium Circle for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

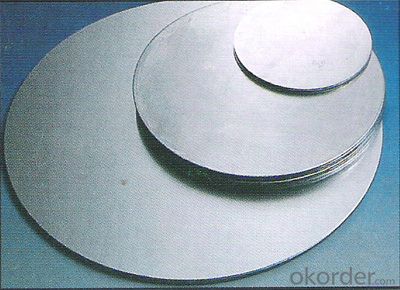

1.Structure of Continuous Casting Mill Finished Aluminium Circle for Cookware

Continuous Casting Mill Finished Aluminium Circle for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Mill Finished Aluminium Circle for Cookware

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Diameter | Weight |

| AA1050 | H18 | 0.2MM-3MM | 100MM-1000MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:Can aluminum coils be used for solar panel applications?

- Yes, aluminum coils can be used for solar panel applications. They are often utilized as the base material for solar panels due to their lightweight, corrosion-resistant, and durable properties. Additionally, aluminum coils offer good thermal conductivity, enabling efficient heat dissipation in solar panels.

- Q:Are aluminum coils suitable for aerospace applications?

- Yes, aluminum coils are suitable for aerospace applications. Aluminum is a widely used material in the aerospace industry due to its excellent properties such as lightweight, high strength-to-weight ratio, corrosion resistance, and good thermal conductivity. These properties make aluminum coils ideal for various aerospace applications, including aircraft structures, wings, fuselage, and engine components. Additionally, aluminum coils can be easily formed into different shapes and sizes, allowing for efficient manufacturing and customization. Overall, the use of aluminum coils in aerospace applications helps to improve fuel efficiency, reduce overall weight, and enhance performance and durability in challenging environments.

- Q:Are aluminum coils suitable for solar panel applications?

- Yes, aluminum coils are suitable for solar panel applications. Aluminum is a lightweight and highly conductive material that has several advantages for solar panels. Firstly, aluminum coils can effectively transfer and dissipate heat, which is crucial for maintaining the efficiency and lifespan of solar panels. Aluminum's excellent thermal conductivity helps in reducing the temperature of the solar cells, preventing overheating and potential damage. Secondly, aluminum coils are highly resistant to corrosion, making them an ideal choice for outdoor solar panel installations. Solar panels are exposed to various weather conditions, including rain, snow, and humidity, which can lead to corrosion and degradation. Aluminum's natural oxide layer acts as a protective barrier, preventing corrosion and increasing the durability of the solar panels. Additionally, aluminum is a cost-effective material that is widely available and easy to manufacture. Its lightweight nature also contributes to easier transportation and installation of solar panels, reducing overall costs. In conclusion, aluminum coils are suitable for solar panel applications due to their excellent thermal conductivity, corrosion resistance, durability, and cost-effectiveness.

- Q:I heared the aluminum weakens or melts.

- Mercury readily combines with aluminium to form a mercury-aluminum amalgam when the two pure metals come into contact. However, when the amalgam is exposed to air, the aluminium oxidizes, leaving behind mercury. The oxide flakes away, exposing more mercury amalgam, which repeats the process. This process continues until the supply of amalgam is exhausted, and since it releases mercury, a small amount of mercury can “eat through” a large amount of aluminium over time, by progressively forming amalgam and relinquishing the aluminium as oxide. Aluminium in air is normally protected by a thin layer of its own oxide, which is not porous to mercury. Mercury coming into contact with this oxide does no harm. However, if any elemental aluminium is exposed (even by a recent scratch), the mercury may combine with it, starting the process described above, and potentially damaging a large part of the aluminium before it finally ends.

- Q:Are aluminum coils suitable for HVAC ductwork?

- Indeed, HVAC ductwork can be furnished with aluminum coils. The lightweight and corrosion-resistant attributes of aluminum coils render them the preferred choice for HVAC ductwork. These coils possess exceptional durability, enabling them to endure extreme temperatures and weather conditions. Additionally, aluminum coils exhibit remarkable thermal conductivity, facilitating efficient heat transfer and ensuring optimal cooling or heating efficacy. Furthermore, aluminum represents a non-toxic material, guaranteeing the safety of its employment in HVAC systems. All in all, aluminum coils serve as an ideal option for HVAC ductwork, furnishing enduring performance and energy efficiency.

- Q:Can aluminum coils be customized?

- Yes, aluminum coils can be customized according to specific requirements. Aluminum coils are highly versatile and can be customized in terms of thickness, width, length, alloy composition, surface finish, and other specifications. This allows for a wide range of applications in various industries such as construction, automotive, aerospace, electronics, and packaging. Customization of aluminum coils can be done through processes like slitting, cutting-to-length, embossing, painting, and coating. This flexibility in customization enables manufacturers to meet the unique needs of their customers and ensures that the aluminum coils are optimized for their intended use.

- Q:What are the different types of aluminum alloys used for making coils?

- There are several different types of aluminum alloys that are commonly used for making coils. These alloys are specifically chosen for their unique properties and characteristics, which make them suitable for various applications. Some of the most widely used aluminum alloys for coils include: 1. Aluminum 1100: This alloy is pure aluminum and is known for its excellent corrosion resistance, high thermal conductivity, and good formability. It is often used in applications where high electrical conductivity is required, such as in transformers or electrical coils. 2. Aluminum 3003: This alloy is known for its moderate strength and excellent workability. It has good corrosion resistance and is often used in applications where formability and resistance to atmospheric corrosion are important, such as in condenser coils or evaporator coils for HVAC systems. 3. Aluminum 5052: This alloy is known for its high strength, excellent corrosion resistance, and good weldability. It is often used in applications where strength and resistance to saltwater corrosion are critical, such as in marine or offshore applications. 4. Aluminum 6061: This alloy is known for its high strength, good corrosion resistance, and excellent machinability. It is often used in applications where high strength and good weldability are required, such as in heat exchanger coils or automotive cooling coils. 5. Aluminum 7075: This alloy is known for its very high strength and excellent fatigue resistance. It is often used in applications where extreme strength and resistance to stress are crucial, such as in aircraft or aerospace components. These are just a few examples of the different types of aluminum alloys used for making coils. The specific alloy chosen depends on the requirements of the application, such as strength, corrosion resistance, formability, or electrical conductivity.

- Q:Can aluminum coils be used in the manufacturing of cans and containers?

- Yes, aluminum coils are commonly used in the manufacturing of cans and containers. Aluminum is lightweight, durable, and resistant to corrosion, making it an ideal material for packaging food and beverages. The coils are typically processed and shaped into desired can or container forms before being used in the manufacturing process.

- Q:Is there any elements that can be added to aluminum to create any compound?

- Which industries? while you're actually not greater particular the checklist can pass on perpetually. i'm going to checklist some nonetheless: Hydrogen-Used to make ammonia and for hydrogenation techniques like the production of liquid fuels and margarine. Ammonia-Used to make fertilizer for agriculture. Sulfuric acid-fabric ending, prescribed drugs, pesticides, oil-nicely acidification, preserving coatings, purification of petrol, manufacture of detergents, explosives....... Carbon-Used for all smelting of metals Iron-For the production of steel. Oxygen-Steelmaking, paint pigment, welding, rocket gas. As you may locate the checklist is getting ridiculous. Sulfuric acid is the main used yet you may look this info up in any good inorganic chemistry textbook.

- Q:I HEARD THAT ALUMINUM POWDER TIGHTEN YOUR VAGINA BUT WHERE DO I BUY IT AND HAVE ANY ONE HEARD OF BEYDARY PILLS, I HEARD THEY TIGHTEN YOUR VAGINA ALSO AND WHERE CAN I BUY THEM

- try leaving it alone for awhile

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Continuous Casting Mill Finished Aluminium Circle for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords