Continuous Casting Aluminium Strip in Coils AA1050

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

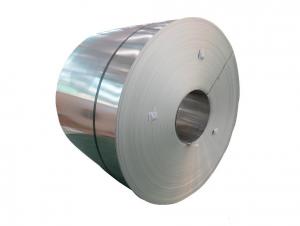

Continuous Casting Aluminium Strip in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4.Products Specification

| Alloy | Final Usage | Coil ID | Coil Weight | Thickness |

| AA1050 | Aluminium coil/circle | 610mm +/-10mm | Min 5 tons | 3-8mm |

5. FAQ

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:Im doing an assignment for science and i need to know the nuclear charge of Aluminium?and also is there a difference between Aluminium and Aluminum or can it just be spelt differently?

- Aluminium is the European spelling Aluminum is the American spelling...just like colour and color. Aluminium ion usually has a 3+ charge

- Q:An aluminum bar 3.80 m long has a rectangular cross section 1.00 cm by 5.00 cm, what is the resistance and what is the length of a copper wire 1.50 mm in diameter having the same resistance?

- I used ρ=2.63 ×10??Ωm for aluminum and got the right answer. The wikipedia page says your aluminum ρ = 2.82×10??Ωm is used for high voltage power lines.

- Q:Are there any restrictions on the coil length of aluminum coils?

- Restrictions do exist regarding the length of aluminum coils. Typically, the maximum coil length is determined by the capabilities of the equipment utilized for coil production and handling. Several factors contribute to this determination, including the dimensions and capacity of coil winding machines, transportation and storage restrictions, and the coil's weight and stability. Moreover, longer coils may encounter increased handling and logistical challenges, such as heightened risk of damage during transportation or difficulties in uncoiling and processing. Consequently, it is crucial to take into account these restrictions and limitations when deciding on the suitable length for aluminum coils.

- Q:How are aluminum coils used in the electrical industry?

- Aluminum coils are widely used in the electrical industry for various applications such as transformers, motors, generators, and electrical transmission systems. These coils are used to create electromagnetic fields, which are essential for the functioning of these electrical devices. Additionally, aluminum coils are preferred due to their lightweight, high thermal conductivity, and cost-effectiveness compared to other materials.

- Q:Can aluminum coils be used for solar panel applications?

- Yes, aluminum coils can be used for solar panel applications. They are often utilized as the base material for solar panels due to their lightweight, corrosion-resistant, and durable properties. Additionally, aluminum coils offer good thermal conductivity, enabling efficient heat dissipation in solar panels.

- Q:Can aluminum coils be used for electrical connectors?

- Certainly! Electrical connectors can indeed utilize aluminum coils. This metal, widely employed for electrical connectors, boasts exceptional electrical conductivity, a relatively affordable price, and lightweight characteristics. It finds extensive application in diverse electrical domains such as power transmission, distribution systems, electrical motors, and transformers. Nonetheless, it is crucial to prioritize adequate insulation and protection for the aluminum coils to avert corrosion and guarantee enduring dependability for the electrical connections.

- Q:G'day guys, I'm wanting to get the tinnie out but im not looking on spending to much on oars, Aluminum ones are quite cheap i can pick some up for $50, but i was just wondering if there any good? anyone had good or bad experience with them? and would it just be worth forking out extra for wooden ones?

- well on a grade 8 camp we went canoeing and had to use aluminium oars and got absolutely cover in grey stuff, like my hands, arms, legs, face. and it made me itchy. it could probably be even cheaper if you made your own wooden ones, like following instructions and everything. but for cheap oars check OKorder

- Q:Can aluminum coils be used for automotive body panels?

- Certainly, automotive body panels can be made using aluminum coils. In fact, aluminum is gaining popularity in the automotive sector due to its numerous advantages. Its lightweight nature contributes to enhanced fuel efficiency and overall vehicle performance. Furthermore, aluminum exhibits exceptional resistance to corrosion, making it a durable option for automotive body panels. Additionally, aluminum can be easily shaped and molded, enabling intricate designs and improved aerodynamics. All in all, utilizing aluminum coils for automotive body panels presents a viable choice with a multitude of benefits.

- Q:Are there any fire safety considerations when using aluminum coils?

- Yes, there are fire safety considerations when using aluminum coils. Aluminum is a highly flammable material and can ignite under certain conditions, such as exposure to high temperatures or direct contact with an open flame. Therefore, it is important to ensure proper insulation and ventilation when using aluminum coils to prevent the risk of fire. Additionally, regular inspections and maintenance should be carried out to identify any potential fire hazards and address them promptly.

- Q:Are aluminum coils suitable for architectural cladding?

- Yes, aluminum coils are suitable for architectural cladding. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it ideal for exterior applications such as cladding. Additionally, aluminum coils can be easily formed and fabricated into various shapes and sizes, providing designers with flexibility in creating unique architectural designs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Continuous Casting Aluminium Strip in Coils AA1050

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords