Construction Heavy Duty Support Steel Props

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Props:

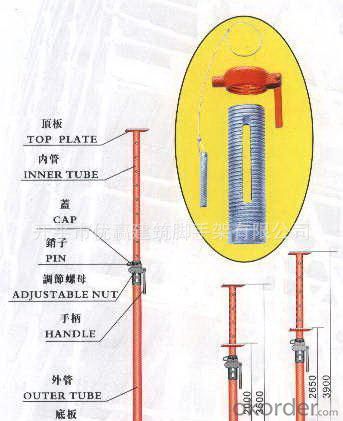

1. Steel Prop consists of internal pipe, external pipe, prop sleeve, nut, pin, top and bottom plate.

2. Steel Prop is widely used as support system in beam, slab, formwork, concrete and floor support.

3. Steel Prop can be surface treatment red oil painting or powder coated or galvanized to further resist rust, cracking and corrosion, has no pollution or harm to the environment and human body, which make sure of its low damage and longer life span.

4. Steel Prop has fewer components, easy and quick assembly.

5. Steel Props has high bearing capacity, as steel pipe material is Q235, thickness can be 1.8mm to 3.0mm, diameter 40-48mm,48-56mm,48-60mm. According to SGS test report, one prop with 2.2mm of thickness, 48-60mm diameter can load 1.8tons, which is heavy duty Steel Props .

6.We can meet all kinds of steel props , Italian tye, Spanish type for South Amercia, Middle East type. aole the requiremnets, such as U head, fork head, rosette head, plate, etc.

Technical parameters

Model Number: adjustable steel prop

Material: Q235 steel tube raw material

Surface Treatment: Galvanized,Dip Painted,Powder coated

Color: silver,dark red,yellow,blue,green and more colore

Application: building construction shoring props for inside concrete wall support

tube thickness: 1.8/2.0/2.2/2.5/3.0mm

adjustable length: 1600-2900/1800-3200/2000-3600/2200-4000mm as your request

base plate size: 120*120*5mm or as your request

Working life: 4-6 years normally

inner tube diameter: 40mm,or 48mm

outer tube diameter: 48mm,or 56/58/60mm

Packaging & Delivery

In bulk or steel pallet. props will be bundle with wooden pallet or bare package in container one 20ft container can load steel props 1800pcs to 2500pcs.

20 to 30 days to main port of China after order confirmation

- Q:How do you prevent steel props from sinking into the ground?

- One way to prevent steel props from sinking into the ground is by using a suitable base plate or foot plate. These plates should be large enough to distribute the weight of the prop over a wider area, reducing the pressure exerted on the ground. Additionally, placing the props on stable and compacted soil can help prevent sinking.

- Q:What are the common signs of wear and tear in steel props?

- Common signs of wear and tear in steel props can vary depending on the specific use and conditions they are subjected to. However, some common signs include: 1. Surface corrosion: Steel props are often exposed to moisture and various environmental conditions, which can lead to surface corrosion. This can manifest as rust spots or discoloration on the steel surface. 2. Deformation: Over time, steel props can undergo deformation due to heavy loads, improper storage, or accidental impacts. Signs of deformation include bending, warping, or buckling of the steel structure. 3. Cracks or fractures: Excessive weight or prolonged use can cause steel props to develop cracks or fractures. These can occur on the main structural elements or at the joints and connection points. 4. Loose or damaged nuts and bolts: Steel props typically use nuts and bolts for connecting various components. With wear and tear, these fasteners can become loose, damaged, or stripped, resulting in reduced stability and safety. 5. Excessive movement or instability: When steel props are subjected to wear and tear, they may exhibit increased movement or instability. This can be observed as wobbling or shaking during use, potentially compromising the structural integrity. 6. Reduced load-bearing capacity: Over time, the load-bearing capacity of steel props can decrease due to material fatigue, corrosion, or other forms of damage. This can be indicated by the prop's inability to support the intended load or by visible signs of stress on the steel structure. 7. Deterioration of protective coatings: Steel props are often coated with protective treatments or paints to enhance their resistance to corrosion. Signs of wear and tear in this regard include peeling, cracking, or chipping of the protective coatings. It is essential to regularly inspect steel props for these signs of wear and tear to ensure their continued safety and performance. If any of these signs are observed, it is recommended to take appropriate measures, such as repairs, replacements, or strengthening, as necessary.

- Q:How do you prevent steel props from sliding on icy surfaces?

- One effective way to prevent steel props from sliding on icy surfaces is by attaching rubber or non-slip pads to the base of the props. These pads provide increased traction and grip, minimizing the chances of sliding. Additionally, ensuring proper weight distribution and stability by placing the props at an appropriate angle can also help prevent sliding on icy surfaces.

- Q:Are steel props resistant to electromagnetic pulses (EMP)?

- No, steel props are not resistant to electromagnetic pulses (EMP). Electromagnetic pulses are intense bursts of electromagnetic energy that can disrupt or damage electronic devices and systems. Steel is a good conductor of electricity and can actually amplify the effects of an EMP by acting as an antenna. Therefore, steel props would not provide any protection against EMPs. To safeguard against EMPs, specialized shielding materials and designs need to be incorporated into the construction of devices or systems.

- Q:Can steel props be used for supporting temporary water treatment infrastructure?

- Indeed, temporary water treatment infrastructure can benefit from the utilization of steel props. Possessing great strength and durability, steel props prove themselves to be highly suitable for offering support to heavy machinery and structures. Within the realm of temporary water treatment infrastructure, steel props find utility in providing support to an array of components including pipes, pumps, tanks, and filtration systems. With the ability to be adjusted to varying heights, these props ensure stability, thereby enabling the water treatment system to operate safely and efficiently. Furthermore, the ease with which steel props can be installed and dismantled renders them a practical choice for temporary infrastructure requirements.

- Q:How do steel props compare to trench jacks in terms of performance?

- When it comes to supporting trenches and excavations, both steel props and trench jacks are commonly used. However, they differ in terms of performance. Steel props, also known as adjustable steel props or acrow props, are telescopic steel tubes that can be adjusted to different lengths. They are designed to provide vertical support to trenches and can be easily customized to fit various heights. Steel props are known for their versatility and can be used in different construction applications, supporting heavy loads. Additionally, they are relatively lightweight and easy to handle. On the other hand, trench jacks have a different design and functionality. They consist of a series of steel bars connected by pins, forming a framework that can be adjusted to fit the width of the trench. Trench jacks are primarily used for smaller and narrower trenches and may have a limited load-bearing capacity compared to steel props. They are generally more suitable for lightweight or temporary support needs. In terms of performance, steel props offer more flexibility and adaptability due to their adjustable lengths. This allows for easy customization according to the specific trench depths and requirements. Moreover, steel props have a higher load-bearing capacity, making them suitable for supporting heavier loads or larger excavations. Their lightweight nature also makes transportation and installation easier. On the other hand, trench jacks may be more suitable for smaller trenches or temporary support needs. They are generally quicker to assemble due to their simple design and can be easily adjusted to fit the width of the trench. However, trench jacks may not be as versatile or capable of handling heavy loads compared to steel props. Ultimately, the choice between steel props and trench jacks depends on the specific project requirements. Factors such as trench size, load-bearing capacity, and the need for adjustability will determine which option is more suitable.

- Q:How do steel props compare to aluminum props in terms of strength?

- Steel props are generally stronger than aluminum props. Steel is a stronger and more rigid material compared to aluminum, which means that steel props have a higher load-bearing capacity. They are able to withstand heavier loads and provide greater support for structures or equipment. Steel props are often preferred in construction and industrial applications where strength and durability are essential. On the other hand, aluminum props are lighter and more corrosion-resistant than steel props, making them suitable for certain applications where weight and resistance to rust are important factors. However, when it comes to sheer strength and ability to handle heavy loads, steel props outperform aluminum props.

- Q:Can steel props be used for supporting temporary power generation infrastructure?

- Yes, steel props can be used for supporting temporary power generation infrastructure. Steel props are strong and sturdy, making them suitable for providing reliable support to the heavy equipment and structures associated with power generation. They can be adjusted to different heights and are commonly used in construction and temporary infrastructure projects, including power generation setups.

- Q:Are steel props adjustable in both lateral and vertical directions?

- Yes, steel props are adjustable in both lateral and vertical directions. They can be extended or retracted to achieve the desired height and can also be tilted or angled to provide lateral support as needed.

- Q:How do you inspect and certify steel props for safe use?

- To ensure the safe use of steel props, a thorough examination of their condition and compliance with industry standards is necessary. The following steps are typically taken to ensure their safety: 1. Visual Inspection: Begin by visually inspecting the steel props for any visible signs of damage such as cracks, bends, or corrosion. It is important to ensure that the props are free from any deformities that could compromise their structural integrity. 2. Verification of Load Capacity: Determine the load-bearing capacity of the steel props by referring to manufacturer specifications, engineering calculations, or load charts. This will ensure that the props are suitable for the intended application and can handle the expected loads. 3. Compliance with Standards: Check if the steel props meet the relevant industry standards and codes. Many countries have specific standards governing the design, manufacturing, and usage of steel props. It is crucial to verify that the props adhere to these standards to ensure their safe use. 4. Non-Destructive Testing: Use non-destructive testing methods such as ultrasonic testing or magnetic particle inspection to detect any hidden defects or cracks in the steel props. This will ensure that even internal flaws are identified and addressed before certifying the props for use. 5. Maintenance Records: Review the maintenance records of the steel props to ensure that they have been regularly inspected, serviced, and maintained in accordance with the manufacturer's recommendations. This will help ensure the ongoing safety and reliability of the props. 6. Certification: After completing all the above steps, issue a certification document stating that the steel props have been inspected and certified for safe use. This document should include details of the inspection, any findings, and the date of certification. It is important to note that the inspection and certification process should be carried out by qualified and experienced individuals who are knowledgeable about the specific requirements and standards associated with steel props. Furthermore, regular inspections and recertification should be conducted periodically to ensure the continued safety of the steel props.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Construction Heavy Duty Support Steel Props

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords