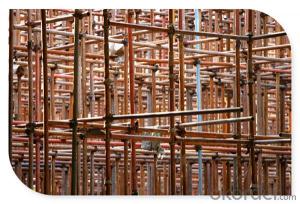

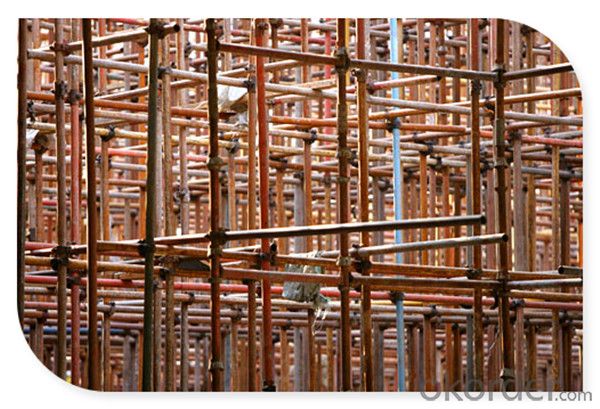

Construction Concrete Slab Formwork Steel Galvanized Cuplock Scaffolding System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Construction Concrete Slab Formwork Steel Galvanized Cuplock Scaffolding System

Name Cuplock Scaffold System Size Many sizes or as your request Main Material Q235/345 Steel Surface Treatment High Protected Painted, Powder Coating, Electric Gavenized, Hot Dip Gavenized. Color Silver, Orange, Red Certificate SGS, EN12810. Service OEM Service available MOQ 50T Payment T/T, Western Union Delivery Time 15-25 days after deposite Packing in bulk or steel pallet or as your request production capability 50 tons per day Main Market Africa, South America, the Middle East and Asia

Descriptions of Construction Concrete Slab Formwork Steel Galvanized Cuplock Scaffolding System

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Steel Cuplock Scaffolding System for Concrete Building Construction

1.Cuplock scaffold system is simple in structure,including top cup,bottom cup and ledger blade.

2.Quick installation of horizontals and verticals,you can easily fit the ledger blade into the cups with a hammer.

3.Cuplock scaffold system standards are made from higher quality steel tube which allow more than 58KN load per leg.

4.Cuplock scaffold system is a multi-functional scaffolding system which is suitable for all forms of access and support structures,especially used in bridege building.

5.People can fasten joint of ledgers by putting two extra ledger blades in the cups.

6.This cuplock scaffold system are interlocked by cups and ledgers which is very safe and stable steel scaffolding system.

7.This is a heavy duty scaffold system which can load about 16tons for each cuplock scaffolding system.

8.Cuplock scaffold system can be used both interior or outerior high-rise building construction project, expecially for arc shape building such as bridge, tunnel, subway, or gym building. it's multifunctional.

9.This is a galvanized cuplock scaffold system which surface is hot dip galvanized, it can keep a longer working life.

10.Gavanized cuplock scaffold system is water-proof scaffold sysem which can prevent the air and water to damage the cups and ledgers very effectively.

11.Cuplock scaffold system can be quick to errect by interting the cuplock blade into bottom cup, then swivel the top cup to fixed it.

12.Suitable for transportation and storage: Single cuplock scaffold system standard and ledger occupy less space. Wiht no extra parts.

The Measures of Construction Concrete Slab Formwork Steel Galvanized Cuplock Scaffolding System

Standard: 3000mm, 2500mm, 2000mm, 1500mm, 1000mm, 500mm.

Ledger: 3000mm, 2000mm, 1780mm, 1500mm, 1000mm, 500mm.

Diagonal brace: 3000X2000mm, 1780X2000mm, 1000X1500mm, 1000X2000mm, 1500X2000mm,

Tube specification: Φ 48.3X4.0mm, φ 48.0 X3.25mm, φ 48.0 X3.0mmFAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:Said chrysanthemum disc scaffolding system, disc scaffolding system, wheel type scaffolding system, buckle scaffold, layher frame

- Crossbar HG-30 3001.67HG-60 6002.82HG-90 9003.97HG-120 12005.12HG-150 15006.28

- Q:Which God can tell me what is required, how to get ah?

- The same height of the building to be calculated separately, and ultimately is to pay attention to security, you can look at the yuan Tuo mall information on this aspect is still a lot of

- Q:What are the common rules for calculating the amount of scaffolding works

- General rules for the calculation of scaffolding:Masonry works (including building blocks) are higher than 1m when calculated by external scaffolding. Independent column height of less than 3.6m according to the core of the core of the circumference of the height of the calculation of the height of the project; the height of more than 3.6m of the column core circumference plus 3.6m multiplied by the actual height of the project to calculate the amount of masonry.

- Q:What are the requirements for the construction of the scaffold eye in the building?

- Optimistic, the most comprehensive!5.2.5 scaffold EngineeringA. accessories(1) selection and calculation basis of structural parts

- Q:What could you do with 100,000 jumbo cotton balls, 50 gallons of honey, and three story scaffolding?

- ummmm oh i got a good one i hope and that is to build the world's largest bee's hive. plus they make more honey and i would have tons of money, pretty sweet isn't it.

- Q:Standard Specification for bowl buckle scaffold

- A new type of scaffold developed in China

- Q:i have some ?'s on the scarlett letterWhat effect has the 7=year interval had on Dimmesdale ?

- you can see how weak morally dimmesdale is, because he keeps his hand over his heart all the time, and is constantly beating himself up over his crime. he whips himself in the closet, and brands himself with a scarlett a to match hesters. hester... when she first walks out on the scaffold she can be seen as defiant, as if she isn't ashamed of the embellished letter a she wears. the cottage she lives in is on the edge of the town, bordering the forest. towards the end of the 7 years, her actions can be seen as repent maybe for her crime: she is a self ordained sister of mercy, helps the poor and homeless, sews... and the a turns from adultery to able

- Q:Exterior wall scaffold construction plan?

- Big bar:The large cross bar is arranged above the cross bar, and the inner side of the vertical rod is fastened with a right angle fastener and a vertical rod, and the length of the utility model is not less than 6m of the span of the 3m. The large cross bar is connected with a butt fastener, and the joint is arranged in a staggered way, not in the same time and in the same distance. The horizontal distance of adjacent joints shall not be less than 50cm. The distance from the joint to the riser is not more than 50cm

- Q:From the Scarlet Letter, Ch. 10-12

- Haven't read this book in years but I believe he goes back to the scaffold at night because he is being eaten away by guilt. It is a type of redemptive action, just as Hester had to stand there and be judged for her sins he feels the need to also stand there on the scaffold with Hester (theoretically) and be judged/punished as well, the only difference, of course, is that he does it under the cloak of night, when no one can see him.

- Q:According to the standard set up double scaffolding scaffolding to the number of meters per square meter

- The span, the rod step is easy to calculate, I have done the program in general 4.4.8 meters

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Construction Concrete Slab Formwork Steel Galvanized Cuplock Scaffolding System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords