Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

Plastic Formwork Concrete Formwork Parts Of A Tubular Scaffolding Scaffolding Importers Low Price

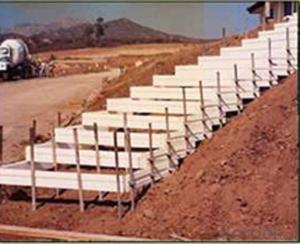

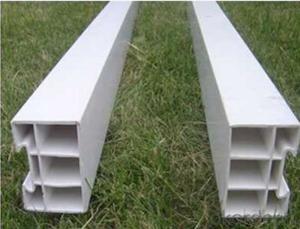

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

FAQ

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

We have organized several common questions for our clients, may help you sincerely:

1)How is the Packaging Details?

In bags or as the requirement ofcustomers.

2)How long can we receive the product after purchase?

Lead time is about 30days after getting the signed PI and deposit.

- Q:Are there any environmental considerations associated with steel frame formwork?

- Yes, there are several environmental considerations associated with steel frame formwork. Firstly, the production of steel involves a significant amount of energy and resources. The extraction of iron ore, processing it into steel, and the transportation of steel all contribute to carbon emissions and environmental degradation. This makes the production of steel frame formwork a carbon-intensive process. Additionally, steel is not a renewable resource. It is extracted from the earth's crust and once it is used, it cannot be easily replenished. This raises concerns about the depletion of natural resources and the long-term sustainability of using steel frame formwork. Furthermore, steel is prone to corrosion, especially when exposed to moisture or chemicals. This can lead to the deterioration of the formwork over time, resulting in the need for replacements and repairs. The disposal of old or damaged steel formwork also poses environmental challenges, as it can contribute to landfill waste. On a positive note, steel frame formwork can be reused multiple times, which helps reduce the overall environmental impact. However, the transportation and handling of the heavy steel frames can still result in additional carbon emissions. To mitigate these environmental considerations, it is important to consider alternative materials for formwork, such as recycled plastic, bamboo, or timber. These materials are renewable, have lower carbon footprints, and can be reused or recycled more easily. Additionally, implementing sustainable practices in the construction industry, such as reducing waste, optimizing design, and improving energy efficiency, can help minimize the environmental impact associated with steel frame formwork.

- Q:How does steel frame formwork handle the placement of precast concrete elements within the concrete structure?

- Steel frame formwork is a versatile and efficient solution that handles the placement of precast concrete elements within the concrete structure effectively. It offers a strong and stable framework for supporting the precast elements during the pouring and curing process. The steel frames can be easily adjusted and customized to accommodate various shapes and sizes of precast elements, ensuring accurate placement and alignment. Additionally, the steel formwork provides a smooth and even surface finish, enhancing the overall appearance and quality of the final concrete structure.

- Q:How does steel frame formwork help in reducing formwork assembly time?

- There are several ways in which formwork assembly time can be reduced with the help of steel frame formwork. To begin with, steel frame formwork is designed to be lightweight and easily adjustable, making it quick and convenient to assemble. The steel frames are typically pre-fabricated and can be easily connected together, allowing for rapid installation. This eliminates the need for complex and time-consuming assembly processes, such as cutting and shaping wooden formwork. Furthermore, steel frame formwork is highly durable and can be reused multiple times. This saves time and effort as the same frames can be used for multiple projects. In contrast, traditional wooden formwork often needs to be built from scratch for each project, increasing the overall assembly time. Moreover, steel frame formwork provides excellent stability and support, reducing the need for additional bracing and support systems. This saves time during assembly as there is no need to spend extra effort on reinforcing the formwork structure. The strong and rigid steel frames can withstand the pressure of the concrete, reducing the risk of formwork failure during the pouring process and minimizing the time spent on repairs or adjustments. Additionally, steel frame formwork allows for efficient and precise concrete pouring. The frames are designed with accurate dimensions, ensuring proper alignment of the formwork. This eliminates the need for extensive adjustments during the pouring process, saving time and reducing the risk of errors. The precise alignment also enables faster removal of the formwork after the concrete has cured, further reducing the overall assembly time. In conclusion, steel frame formwork contributes to a faster and more efficient construction process by offering a lightweight and easily adjustable design, durability for multiple uses, stability and support, and efficient concrete pouring capabilities. These features result in reduced formwork assembly time, ultimately improving overall productivity.

- Q:What are the different finishes available for steel frame formwork panels?

- There are several different finishes available for steel frame formwork panels, depending on the specific requirements of the construction project. Some of the most common finishes include: 1. Smooth Finish: This is the most basic finish option, where the steel frame formwork panels are left with a smooth surface. This finish is suitable for projects where a smooth concrete surface is desired. 2. Textured Finish: In some cases, a textured finish is preferred to provide better adhesion between the concrete and the formwork. This can be achieved by adding a texture to the surface of the steel frame formwork panels. 3. Powder Coating: Powder coating is a popular finish option for steel frame formwork panels. It involves the application of a dry powder to the surface, which is then heated to form a durable and protective coating. Powder coating can provide a smooth, even finish and can also offer enhanced corrosion resistance. 4. Galvanizing: Galvanizing is a process where a protective layer of zinc is applied to the surface of the steel frame formwork panels. This coating not only provides corrosion resistance but also improves the overall durability of the panels. 5. Paint Coating: Paint coating is another option for finishing steel frame formwork panels. It involves the application of a liquid paint to the surface, which provides both aesthetic appeal and protection against corrosion. It is important to consider factors such as durability, corrosion resistance, and aesthetic requirements when choosing the appropriate finish for steel frame formwork panels. Consulting with a construction professional or engineer can help determine the best finish option for a specific project.

- Q:Can steel frame formwork be used for the construction of agricultural buildings?

- Indeed, the utilization of steel frame formwork is feasible for the erection of agricultural edifices. With its versatility and durability, steel frame formwork serves as a commendable option for a diverse range of construction undertakings, including agricultural buildings. Its capacity to provide strength, stability, and reusability renders it suitable for agricultural structures necessitating robust and enduring construction materials. Moreover, the ease of assembly and disassembly of steel frame formwork facilitates efficient construction processes within agricultural settings. Thus, whether the objective is to construct barns, sheds, or any other agricultural buildings, opting for steel frame formwork ensures both structural integrity and long-lasting construction.

- Q:How does steel frame formwork handle concrete curing in dry conditions?

- Steel frame formwork, composed of steel frames, is utilized to support and secure the concrete while it cures. When it comes to dealing with concrete curing in arid conditions, steel frame formwork proves to be a dependable and effective option. A primary advantage of steel frame formwork lies in its ability to provide a robust and stable support system during the curing process. The design of the steel frame enables it to withstand the pressure and weight of the concrete, guaranteeing its stability and preventing collapse or deformation. This feature is particularly crucial in dry conditions, where the absence of moisture heightens the risk of concrete cracking or shrinking. Furthermore, steel frame formwork exhibits exceptional resistance against warping or bending due to its inherent strength and rigidity. Consequently, the formwork maintains its shape and stability even in dry conditions, allowing for uniform concrete curing without any distortion or deformity. Additionally, steel frame formwork allows for easy adjustments or modifications to accommodate diverse concrete curing requirements. The modular construction of the steel frames facilitates convenient assembly and disassembly, making it effortless to adapt the formwork to various shapes and sizes of concrete structures. This flexibility proves particularly advantageous in dry conditions, where the absence of moisture may necessitate alterations in the curing process. Moreover, steel frame formwork yields a smooth and even surface finish on the cured concrete, a critical aspect for achieving high-quality outcomes. The steel frames are typically coated or treated to prevent corrosion or rusting, ensuring that they do not leave any undesirable marks or stains on the cured concrete surface. Overall, steel frame formwork stands as an ideal solution for managing concrete curing in dry conditions. Its strength, stability, adjustability, and ability to provide a smooth finish make it a reliable and efficient choice, ensuring successful concrete curing even in arid environments.

- Q:What are the different types of lifting inserts used with steel frame formwork?

- Steel frame formwork can be paired with several types of lifting inserts to facilitate the secure and efficient movement of the formwork. Among the available options is the threaded lifting insert. This insert incorporates a threaded rod that is embedded into the formwork. By attaching a lifting eye or hook to the threaded rod, individuals can easily lift and transport the formwork. Another alternative is the recessed lifting insert. This particular insert is embedded into the formwork and features a recessed area where a lifting eye or hook can be affixed. The recessed design effectively shields the lifting insert from potential damage during usage. Moreover, magnetic lifting inserts are also accessible. These inserts employ powerful magnets to securely hold the formwork in place while it is being lifted and moved. Their easy attachment and detachment from the formwork make them incredibly convenient and efficient. Certain lifting inserts additionally possess a swivel design, enabling a full 360-degree rotation of the formwork during lifting and transportation. This swivel capability ensures accurate and secure positioning of the formwork. In summary, the assortment of lifting inserts compatible with steel frame formwork offers various options for safely and effectively lifting and moving the formwork. The choice of which type to employ hinges on factors such as project-specific requirements, formwork weight, and the desired level of convenience and efficiency.

- Q:How does steel frame formwork handle vertical and horizontal loads?

- Steel frame formwork is designed to handle both vertical and horizontal loads efficiently. The rigid structure of the steel frame provides excellent resistance against vertical loads such as the weight of concrete, construction equipment, and workers. Additionally, the horizontal loads generated by wind or lateral forces are effectively counteracted by the robustness and stability of the steel frame formwork system. This ensures that the formwork remains stable and reliable, providing a safe working environment for construction activities.

- Q:How does steel frame formwork contribute to the overall versatility of a construction project?

- Steel frame formwork contributes to the overall versatility of a construction project by providing a highly adaptable and reusable system for creating concrete structures. Its modular design allows for easy assembly and disassembly, enabling quick adjustments or changes to the formwork layout. Additionally, the strength and durability of steel make it capable of supporting large concrete loads and withstanding harsh construction conditions. This versatility allows for the construction of various types of structures, shapes, and sizes, making steel frame formwork an essential tool in modern construction projects.

- Q:Can steel frame formwork be used for underwater concrete construction?

- Underwater concrete construction can utilize steel frame formwork as it offers various advantages. The durability, strength, and ability to withstand different environmental conditions make steel frame formwork a popular choice in construction projects. One advantage of steel frame formwork is its high resistance to corrosion, which is essential in underwater environments where the concrete is constantly exposed to water and moisture. The steel can endure the corrosive effects of saltwater and other chemicals found in the water, ensuring the long-lasting and structurally sound underwater concrete construction. Moreover, steel frame formwork provides exceptional stability and support, making it suitable for underwater applications. The rigid steel frames can withstand the water pressure and maintain the integrity of the formwork during the concrete pouring process. This stability is crucial in achieving the desired shape and dimensions of the underwater concrete structure. Additionally, the installation and removal of steel frame formwork are easy and efficient. The modular design of the formwork system allows for quick assembly and disassembly, which is convenient for underwater construction projects where time is often a critical factor. The flexibility of steel frame formwork also enables easy adjustments and modifications, ensuring precise concrete placement. In conclusion, steel frame formwork is an appropriate choice for underwater concrete construction due to its corrosion resistance, stability, and ease of installation. It provides a reliable and efficient solution for creating durable and strong underwater structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords