Concrete Roof Brick Slab Making Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Roof Brick Slab Making Machinery

1. Structure of Concrete Roof Brick Slab Making Machinery:

Concrete Roof Brick Slab Making Machinery works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to forming the concrete hollow-core slab. The slab have the advantages of smooth surface, high-density structure, capable of making construction slabs of 4.2m to 18m. The GLY series concrete hollow-core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

2. Main Features of Concrete Roof Brick Slab Making Machinery:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Concrete Roof Brick Slab Making Machinery Images:

4. Concrete Roof Brick Slab Making Machinery Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

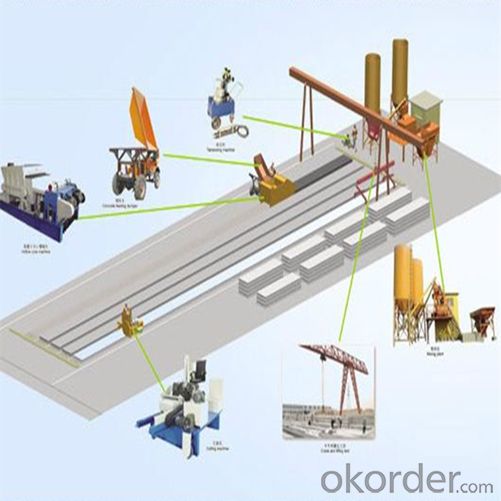

Production Layout

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q:where can i get the plant layput & list of machinery along with market value?

- For what kind of company?

- Q:Metal forming and processing methods which have their own characteristics and scope of application

- Forging processing is a combination of forging and stamping processing, is the use of forging machinery hammer, anvil, punch or general mold on the blank pressure, the blank plastic deformation, access to the required parts of the metal material forming method. Forging the workpiece size is accurate, suitable for mass production. After the workpiece mechanical properties of the workpiece is significantly provided, but the corresponding high cost of manufacturing, can only be processed plastic high metal materials.

- Q:How come Chinese people make farming machinery whereas black African people do not and thus have famines?

- Africa does not have a lot of fertile land. Drought does not promote farming. The entire economy of the African continent relies mostly on charities. Lack of money to buy machinery

- Q:A. physicalB. intangibleC. tangibleD. transient

- i guess c

- Q:this is according to marx, i think its to do with how machinery changed society from primitive to industrial, im not sure tho, any help would be gratefully appreciatedthanks

- social relationships are transformed into apparently objective relationships between commodities or money. workers are alienated from their work due to increase machinery

- Q:Each part adds to the length of each item. There are 2 parts with a length of 3/4 inches, and 3 parts with a length of 1 5/8.What is the total length of machincery?a) 1 1/4 in b) 4 7/8 in c)5 1/8 in d)6 3/8in

- D

- Q:I want to to start designing and building my own mechanics are there any books or dvds that I can buy or is there any online forums that could give me advice

- www.okorder

- Q:Which machinery makes this type of packaging /bags?

- I don't like links.

- Q:Do engineering technicians get to invent and patent ideas within large companies, or is this typically reserved for the mechanical engineers?

- Mostly, engineer's are problem solver's. In the case of mechanical engineers. you are partly correct. They are given a problem, like they need a machine that can build a part or perform some action, but has to fit within certin peramiters. So the engineer has to figure out how to make it work. But this is only a small part of what an engineer does.

- Q:I was wondering if a license from another country (say Ecuador) is valid here in the United States for operating heavy machinery? if not, what are the steps for a non-english speaking person to get this license if they know how to operate machines efficiently?

- Nope. Depending on where you live determining what u can do

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Roof Brick Slab Making Machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords