Concrete Pump Truck Parts Elbow Bend DN100 R275 90DGR 148MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1. Adopt the new plasma quenching and chromium plating process, which increases the concrete conveying life and reduces the frequency of replacement, saving the cost for the customers.

2. Service life: 55000-150000 CBM Concrete. The inner side of this concrete pump elbow undergoes heat treatment, and then the hardness can reach 68HRC.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market.

5. We can supply OEM service and can also produce according to your requirements.

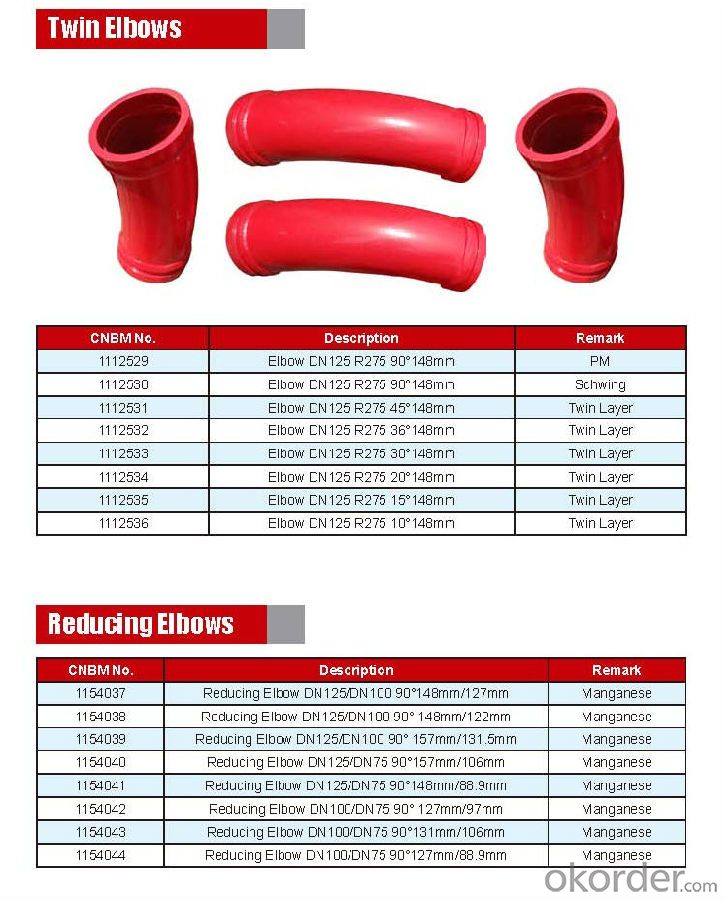

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

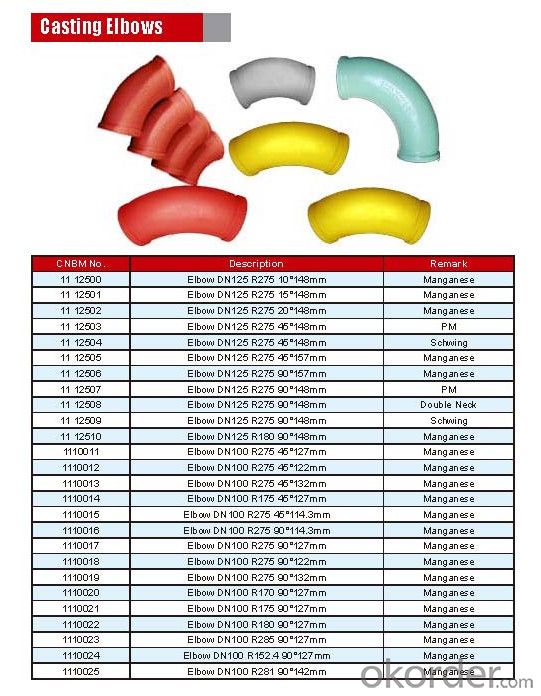

Product Specifications:

Technology: Cast

Dimension: DN100

Radius: 275mm

Degree: 45D

Material: Mn13-4

Weight: 6kg

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Every 140pcs put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q:How often should hopper vibrators be inspected or replaced in a concrete pump?

- To ensure the proper functioning of hopper vibrators in a concrete pump and prevent any potential problems, it is important to conduct regular inspections. The frequency of these inspections or replacements may vary depending on several factors, such as the intensity of use, operating conditions, and the manufacturer's recommendations. As a general rule, it is recommended to inspect hopper vibrators at least once a year or after every 500-600 hours of operation, whichever comes first. However, if the concrete pump is heavily used or operates in harsh environments, more frequent inspections may be necessary. During the inspection, it is essential to check the hopper vibrators for any signs of wear, damage, or loose connections. Additionally, the vibration intensity and frequency should be assessed to ensure they are within the recommended range. Any issues identified during the inspection should be promptly addressed through repairs or replacements to ensure the hopper vibrators continue to function effectively. Regular inspections and timely replacements of hopper vibrators are crucial for maintaining the efficiency and reliability of a concrete pump. Neglecting these inspections can result in decreased performance, increased downtime, and potentially expensive repairs. Therefore, it is important to adhere to the manufacturer's guidelines and seek professional advice to determine the appropriate frequency for inspections and replacements based on the specific circumstances of your concrete pump.

- Q:How do I determine the correct temperature ratings for concrete pump spare parts?

- To determine the correct temperature ratings for concrete pump spare parts, you should refer to the manufacturer's guidelines or specifications. These documents usually provide information on the recommended temperature range within which the parts can function effectively and safely. It is essential to follow these guidelines to ensure the longevity and performance of the spare parts in your concrete pump system.

- Q:How do I maintain and clean concrete pump spare parts?

- Maintaining and cleaning concrete pump spare parts involves regular inspections, lubrication, and following proper cleaning procedures. Firstly, conduct routine checks to identify any signs of wear, damage, or loose connections. Lubricate the moving parts as recommended by the manufacturer to ensure smooth operation and prevent rust. When cleaning, use a mild detergent and water solution to remove any dirt, debris, or concrete residue. Avoid using harsh chemicals or abrasive tools that could damage the parts. It's crucial to follow the manufacturer's guidelines and consult the equipment manual for specific instructions on maintaining and cleaning concrete pump spare parts.

- Q:How often should hopper grate pin retainers be inspected or replaced in a concrete pump?

- Hopper grate pin retainers in a concrete pump should be inspected regularly, ideally on a monthly basis, to ensure their proper functioning and prevent any potential issues. However, the frequency of inspections may vary depending on the specific conditions of use and the manufacturer's recommendations. During these inspections, it is essential to check for any signs of wear, damage, or corrosion on the hopper grate pin retainers. If any of these issues are detected, immediate replacement is necessary to maintain the efficiency and safety of the concrete pump. Additionally, it is crucial to adhere to the manufacturer's guidelines regarding the lifespan of the hopper grate pin retainers. Some manufacturers may recommend replacing them after a certain number of operating hours, while others may suggest replacement based on the visual condition during inspections. Regular inspections and timely replacement of hopper grate pin retainers are crucial to prevent potential malfunctions or accidents during concrete pumping operations. It is always recommended to consult the concrete pump's manual or contact the manufacturer for specific guidelines regarding the inspection and replacement intervals for hopper grate pin retainers.

- Q:How can one ensure proper documentation and record-keeping for concrete pump spare parts?

- One can ensure proper documentation and record-keeping for concrete pump spare parts by implementing a structured system. This system should include keeping a detailed inventory of all spare parts, including their quantities, descriptions, and specifications. Additionally, it is essential to maintain a log of all incoming and outgoing spare parts, noting the date, purpose, and responsible personnel. Regular audits and reconciliations should be conducted to ensure accuracy and identify any discrepancies. Proper labeling and organization of physical storage areas, as well as digitizing records, can further enhance efficiency and accessibility. Regular training and clear guidelines for staff involved in handling spare parts documentation will also contribute to maintaining accurate records.

- Q:How to operate the concrete pump?

- The size of sand and gravel, cement mark and mixture ratio should meet the requirement of the mechanical performance of the pump according to the specifications of the factory

- Q:What are the signs of a malfunctioning gearbox?

- There are several signs that can indicate a malfunctioning gearbox in a vehicle. One of the most common signs is difficulty shifting gears. If you notice that it is becoming increasingly difficult to shift gears smoothly or if you experience grinding or clunking noises when shifting, it could be a sign of a problem with the gearbox. Another sign of a malfunctioning gearbox is slipping gears. This occurs when the gearbox fails to stay in the selected gear and instead slips into a different gear, often resulting in a loss of power or acceleration. You may also notice that the engine RPMs increase without a corresponding increase in speed. Leaking transmission fluid is another indicator of a faulty gearbox. Transmission fluid is essential for lubricating and cooling the gears, so any leakage can lead to overheating and damage to the gearbox components. If you notice red or brown fluid underneath your vehicle, it could be a sign of a leaking gearbox. Unusual noises, such as whining, humming, or clunking sounds, can also be a sign of gearbox issues. These noises may occur while driving, particularly during acceleration or deceleration, and can indicate problems with the gears or bearings within the gearbox. Finally, if you experience a burning smell coming from the engine or gearbox area, it could be a sign of overheating or excessive friction within the gearbox. This can be caused by low or contaminated transmission fluid, worn-out gears, or a malfunctioning cooling system. If you notice any of these signs, it is important to have your vehicle inspected by a qualified mechanic as soon as possible. Ignoring gearbox issues can lead to further damage and potentially costly repairs.

- Q:Are there any specific guidelines for the installation of pistons or cylinders in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of pistons or cylinders in concrete pump spare parts. It is important to follow manufacturer instructions and recommendations for proper alignment, lubrication, and torque specifications during installation. Additionally, regular inspection and maintenance are crucial to ensure optimal performance and longevity of the pump parts.

- Q:Are there any specific guidelines for the installation of control panels or electronic components in concrete pump spare parts?

- Specific guidelines exist for the installation of control panels or electronic components in concrete pump spare parts. When installing such components, it is important to consider the following guidelines: 1. Protection from Moisture: Electronic components can be damaged by moisture, so it is advisable to install them in waterproof or moisture-resistant enclosures to prevent damage from water or humidity. 2. Vibration and Shock Absorption: To avoid damage, it is recommended to use shock-absorbing mounts or vibration-resistant enclosures to minimize the impact of vibration and shock on control panels or electronic components. 3. Temperature Control: Extreme temperatures can affect concrete pump spare parts, so it is crucial to install control panels or electronic components in a temperature-controlled environment. This may involve using insulation or cooling systems to maintain a suitable operating temperature. 4. Wiring and Connections: Proper wiring and connections are essential for the functioning of control panels or electronic components. It is important to follow the manufacturer's instructions and guidelines for wiring, ensuring secure connections and providing adequate insulation and protection against short circuits or electrical hazards. 5. Accessibility and Maintenance: Control panels or electronic components should be installed in a way that allows easy access for maintenance and repairs. Sufficient space should be left around the components for easy inspection, servicing, and replacement if needed. By adhering to these guidelines, the installation of control panels or electronic components in concrete pump spare parts can be carried out to ensure their long-term functionality and durability.

- Q:How do concrete pump spare parts contribute to the overall performance of the pump?

- Concrete pump spare parts play a crucial role in maintaining the overall performance of the pump. These spare parts, such as pipes, hoses, valves, and wear plates, ensure the smooth functioning of the pump by minimizing downtime and improving efficiency. They help in maintaining a consistent flow of concrete, preventing clogs and leaks, and enhancing the accuracy of the pumping process. Regular maintenance and replacement of these spare parts not only extend the lifespan of the pump but also contribute to its reliable and optimal performance, ultimately leading to increased productivity and customer satisfaction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Pump Truck Parts Elbow Bend DN100 R275 90DGR 148MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords