Concrete Pump Truck Parts Elbow Bend DN100 R275 90DGR 114.3MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 70 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1. Mainly adopt high wear resistant steel, and other material upon your request. High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.

2. The inner side of this concrete pump elbow undergoes heat treatment, and then the hardness can reach 68HRC. The elbow possesses good toughness properties, and can well protect the inside. The experiment done abroad shows that the life of our concrete pump elbow can reach 35000-150000cbm,got the customers' praise.

3. Possess quality certification of ISO 9001:2000.

4. A wide range of specifications for you.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

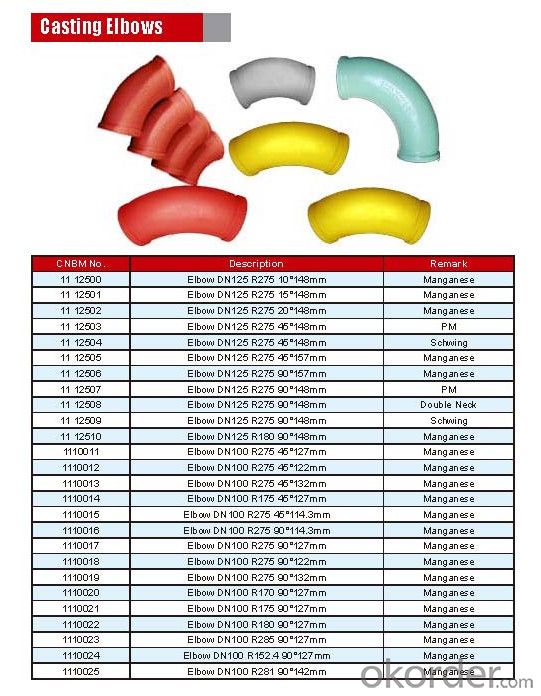

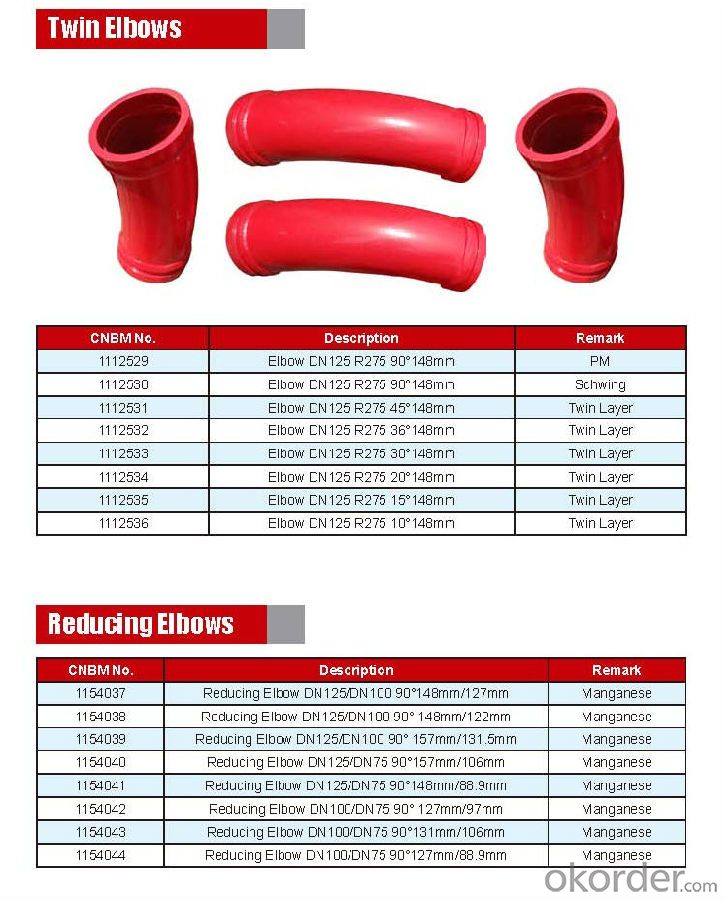

Product Specifications:

Technology: Cast

Dimension: DN100

Flange: 114.3mm

Radius: 275mm

Degree: 90D

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Every 70pcs put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q:What are the advantages of using polyurethane components in concrete pump spare parts?

- There are several advantages of using polyurethane components in concrete pump spare parts. Firstly, polyurethane is highly durable and resistant to wear and tear, ensuring longer lifespan and reduced maintenance costs. Secondly, polyurethane has excellent abrasion resistance, which allows it to withstand the harsh conditions and high pressures involved in concrete pumping. Additionally, polyurethane components offer superior flexibility, allowing for easier installation and reduced risk of breakage. Lastly, polyurethane is known for its chemical resistance, ensuring that the spare parts can withstand exposure to various chemicals and substances commonly found in concrete. Overall, using polyurethane components in concrete pump spare parts provides enhanced durability, flexibility, and resistance to abrasion, making it a preferred choice in the construction industry.

- Q:How often should concrete pump seals be replaced?

- Concrete pump seals should be replaced every 500 to 800 hours of operation or whenever signs of wear, leakage, or decreased performance are observed.

- Q:Can I get spare parts for both concrete pumps with and without lubrication systems?

- Yes, spare parts are available for both concrete pumps with and without lubrication systems.

- Q:What are the advantages of using OEM (Original Equipment Manufacturer) concrete pump spare parts?

- There are several advantages to using OEM (Original Equipment Manufacturer) concrete pump spare parts: 1. Quality Assurance: OEM spare parts are manufactured by the same company that produces the original equipment. This ensures that the parts are made to the same high-quality standards as the original components. The use of OEM parts guarantees that the concrete pump will perform at its optimal level and minimize the risk of breakdowns or failures. 2. Compatibility: OEM spare parts are specifically designed to fit perfectly with the original equipment. They are built to the exact specifications and dimensions required for seamless integration with the concrete pump. This compatibility ensures that the parts will function properly and efficiently. 3. Reliability: OEM spare parts are tested extensively by the manufacturer to ensure their reliability and durability. This means that they are less likely to fail or wear out prematurely, resulting in reduced downtime and maintenance costs. The reliability of OEM parts also minimizes the risk of accidents or injuries caused by faulty equipment. 4. Warranty Coverage: Many OEM spare parts come with a warranty from the manufacturer. This warranty provides protection against defects or failures, giving customers peace of mind and assurance that they are investing in high-quality components. In case of any issues, the manufacturer will typically provide support and assistance in resolving the problem. 5. Technical Support: OEM manufacturers typically offer technical support and assistance to customers using their spare parts. This support can be invaluable when it comes to troubleshooting issues, providing guidance on installation or maintenance, or offering advice on optimizing the performance of the concrete pump. This level of support may not be available when using non-OEM parts. 6. Long-Term Cost Savings: Although OEM spare parts may have a higher upfront cost compared to non-OEM alternatives, they often prove to be more cost-effective in the long run. Their superior quality and reliability result in fewer breakdowns, reduced maintenance expenses, and extended equipment lifespan. The use of OEM parts also helps to maintain the resale value of the concrete pump. In conclusion, the advantages of using OEM concrete pump spare parts include quality assurance, compatibility, reliability, warranty coverage, technical support, and long-term cost savings. By opting for OEM parts, users can ensure the smooth and efficient operation of their concrete pump while minimizing risks and maximizing the return on their investment.

- Q:In general, how much concrete will be transported per hour for the concrete pump and the pump?

- The length of day pump 36-62m, the efficiency has little effect, regular work is generally 30-40 cubic / hour

- Q:How often should concrete pump control panels be inspected and replaced?

- Concrete pump control panels should be inspected regularly, ideally on a monthly basis, to ensure they are functioning properly and to identify any potential issues. However, the frequency of replacement will depend on the specific condition of the control panel, as well as the manufacturer's recommendations. If any signs of wear or malfunction are detected during the inspection, it may be necessary to replace the control panel sooner.

- Q:How do I properly maintain and replace rubber pistons in concrete pump spare parts?

- Maintaining and replacing rubber pistons in concrete pump spare parts is crucial for the efficient operation of the pump and to ensure a longer lifespan of the equipment. Here are some steps to properly maintain and replace rubber pistons in concrete pump spare parts: 1. Regular Inspection: It is important to inspect the rubber pistons regularly to identify any signs of wear or damage. Look for cracks, tears, or any other visible signs of deterioration. 2. Cleaning: Before replacing the rubber pistons, make sure to thoroughly clean the area around the pistons. Remove any dirt, debris, or concrete residue that may be present. This will help prevent contamination and ensure a proper fit for the new pistons. 3. Proper Lubrication: Apply a suitable lubricant to the rubber pistons to ensure smooth operation and reduce friction. This will help prolong the life of the pistons and prevent premature wear. 4. Correct Installation: When replacing the rubber pistons, ensure they are properly installed according to the manufacturer's instructions. Use the correct tools and techniques to avoid damaging the pistons or other components of the pump. 5. Quality Replacement Parts: Always use high-quality replacement rubber pistons from reputable suppliers. Inferior quality pistons may not perform as well and could result in frequent replacements or damage to the pump. 6. Regular Maintenance: Implement a regular maintenance schedule for your concrete pump, including the rubber pistons. This can include cleaning, lubrication, and inspection of the pistons to identify any signs of wear or damage before they become major issues. 7. Training and Expertise: Ensure that the person responsible for maintaining and replacing the rubber pistons has the necessary training and expertise. This will help ensure the job is done correctly and minimize the risk of damage to the pump or injury to personnel. By following these steps, you can properly maintain and replace rubber pistons in concrete pump spare parts, ensuring optimal performance and longevity of the equipment.

- Q:Are there any specific cleaning and maintenance procedures for concrete pump spare parts?

- Concrete pump spare parts require specific cleaning and maintenance procedures to ensure their proper functioning. Regular cleaning is crucial to remove any concrete buildup or residue from the parts. This can be achieved by either using a high-pressure water jet or immersing the parts in a cleaning solution specifically designed for concrete. It is vital to adhere to the manufacturer's instructions when using cleaning agents to guarantee the safety and effectiveness of the cleaning process. Furthermore, routine maintenance is necessary to extend the lifespan of the concrete pump spare parts and ensure their optimal performance. This involves inspecting the parts for any signs of wear, such as cracks or corrosion, and replacing them if needed. It is also important to lubricate the moving parts, like bearings or pistons, according to the manufacturer's recommendations. It is worth noting that different concrete pump spare parts may have unique cleaning and maintenance requirements. Therefore, it is advisable to consult the manufacturer's guidelines or seek guidance from a qualified technician to determine the appropriate procedures for each specific part.

- Q:Are there any specific guidelines for the installation of pistons or cylinders in concrete pump spare parts?

- Installing pistons or cylinders in concrete pump spare parts requires adherence to specific guidelines. These guidelines play a vital role in guaranteeing the equipment's functionality and durability. 1. Thoroughly clean and inspect: Before installation, it is imperative to meticulously clean and inspect the pistons or cylinders to detect any damage or defects. Eliminating any debris or contaminants is essential to avoid potential operational issues. 2. Apply suitable lubrication: To minimize friction and ensure smooth movement, it is necessary to apply an appropriate lubricant to the piston or cylinder. This step also aids in preventing premature wear and tear, thereby extending the parts' lifespan. 3. Ensure proper alignment: Achieving proper alignment between the piston and cylinder is crucial. The piston must be correctly aligned with the cylinder bore to prevent binding or excessive wear. This can be accomplished by following the manufacturer's instructions or seeking professional guidance, if needed. 4. Adhere to torque specifications: Bolts or fasteners must be tightened according to the manufacturer's recommended torque specifications. Over-tightening or under-tightening can result in leaks or mechanical failure. 5. Use adequate sealing materials: To maintain an effective seal between the piston and cylinder, appropriate sealing materials such as gaskets or O-rings must be utilized. This prevents fluid leakage and preserves the equipment's efficiency. 6. Perform thorough testing: After installation, it is advisable to conduct tests to ensure the pistons or cylinders are functioning correctly. This may involve trial runs or pressure testing to identify any leaks or abnormalities. By adhering to these guidelines, the installation of pistons or cylinders in concrete pump spare parts can be executed accurately, resulting in reliable and efficient equipment operation. Referring to the manufacturer's instructions or seeking professional assistance is recommended if any doubts or concerns arise during the installation process.

- Q:How long does it take to replace a specific concrete pump spare part?

- The duration required to replace a specific spare part for a concrete pump can vary based on several factors. Initially, the replacement time will be influenced by the complexity and size of the part. Smaller and simpler parts can be swapped out relatively quickly, whereas larger and more intricate components may necessitate a lengthier process. Additionally, the availability of the spare part is a crucial consideration. If the part is readily accessible and in stock, the replacement procedure can be expedited. Conversely, if the part must be ordered or obtained from a supplier, there may be a delay in receiving it, thereby extending the overall replacement time. Moreover, the competence and experience of the individual or team carrying out the replacement will also impact the duration. Trained and skilled professionals are likely to complete the replacement more efficiently compared to those with limited knowledge or experience. Lastly, unforeseen complications or issues that arise during the replacement process can also affect the time required. It is possible that additional repairs or adjustments may be necessary, which could further prolong the replacement time. In conclusion, the duration for replacing a specific spare part for a concrete pump is dependent on the part's complexity and size, its availability, the expertise of the individuals performing the replacement, and any unforeseen complications that may arise. Therefore, it is challenging to provide an exact timeframe without taking these factors into consideration.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Pump Truck Parts Elbow Bend DN100 R275 90DGR 114.3MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 70 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords