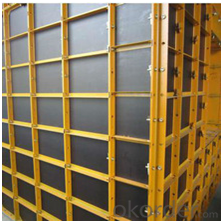

Concrete plywood formwork system Concrete plywood formwork system

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 mm

- Supply Capability:

- 30000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

Transference to concrete is set up very easily. There is no need for any transference preparation.

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

advantages

1.Lightweight, resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut. it is more available with high-rise building and bridge construction.

2.Treating the film faced plywood’s edges with waterproof paint makes it highly water-and wear-resistant.

3.Due to its durability and easily handled surface it can be used in open environment in construction and building e.g. warehouses, railway wagons, floors and sidewalls of trucks etc. Corrosion resistance: not pollute the concrete surface.

4.Coating the film faced plywood with high-quality import films ensures hardness and damage resistance. The surface of the film faced plywood is hygienic and resistant to strong

detergents, which is important for farming constructions and storage of food products.

5.It can be used in conditions of high temperature drop, influence of moisture, detergent cleaning and provides protection against termites. Heat preservation performance is good, be helpful for winter construction. You don’t need to worry about the quality.

- Q:The use of foam sandwich panels erection of the temporary board of the building components of the combustion than the A-level, to rectification, how to engage in ah

- Foam sandwich board where are lower than the A-level, but still someone use, because the convenience, the price is low, so let you rectification is to let you ask you to pay for it

- Q:100 thick composite sandwich board how much money a square meter upper plate 0.6 lower 0.4

- More than sixty yuan / square meters ---- ordinary materials.

- Q:Eps sandwich board and Caigang sandwich board is not two kinds of materials to the two of the price?

- Yes, EPS is glass steel surface, color steel sandwich board is color steel surface, EPS expensive, the difference is about 100 per meter

- Q:Build a color steel sandwich panel production plant how much money

- The general machine price of 25 million or so, the venue costs plus how much raw materials you need, you can run the general about 100 million, but the funds to return to the fast, can not have too much debt.

- Q:There is a phone call

- According to the production method points: continuous plate and non-continuous plate. According to the panel material points: Caigang sandwich panels and cement sandwich panels According to the use of points: cold storage board and wall panels (cold storage board is generally non-continuous plate, the outer wall is generally continuous plate) ? In addition, according to the thickness of polyurethane foam, flame retardant grade and panel thickness, the price range. ? Generally calculate the price per square meter.

- Q:Hard polyurethane sandwich board combustion performance?

- According to the industry standard JCT 868-2000 metal surface rigid polyurethane sandwich panels, sandwich panels combustion performance should reach B1 level. Classification of combustion performance grade in accordance with national standards GB 8624-1997.

- Q:What is the difference between nine and sandwich panels?

- The usual nine PCT board is a multi-layer board, a layer of layers together, hardness, flatness is better, you can do floor floor. Sandwich panels refers to woodworking board, and some places called Daixin board, do furniture with much more.

- Q:What is eps insulation corrugated sandwich panels

- EPS Chinese name is made of polystyrene, polystyrene resin is the third largest variety, the relative density of 1.05 ~ 1.06, heated to 90 ~ 110 degrees, the volume can be expanded 5 to 50 times, is a heat, Noise, shock, water, acid and other properties of foam.

- Q:What is the fire resistance time of the steel wool

- Fire detection report is half an hour

- Q:Domestic manufacturers of rock wool sandwich panel machine which quality is better? What is the price in general?

- My company is using OKorder Yongming, spent more than six years. I personally feel that quality can be. My friend is using the other manufacturers in OKorder, you can also use, the domestic manufacturers in OKorder is doing a little better. As for the price, a price of a cargo, the landlord can visit more, the domestic production of such equipment manufacturers concentrated in OKorder and Hebei.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete plywood formwork system Concrete plywood formwork system

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 mm

- Supply Capability:

- 30000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords