Concrete hollow wallpanel machine HQJ150-600

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

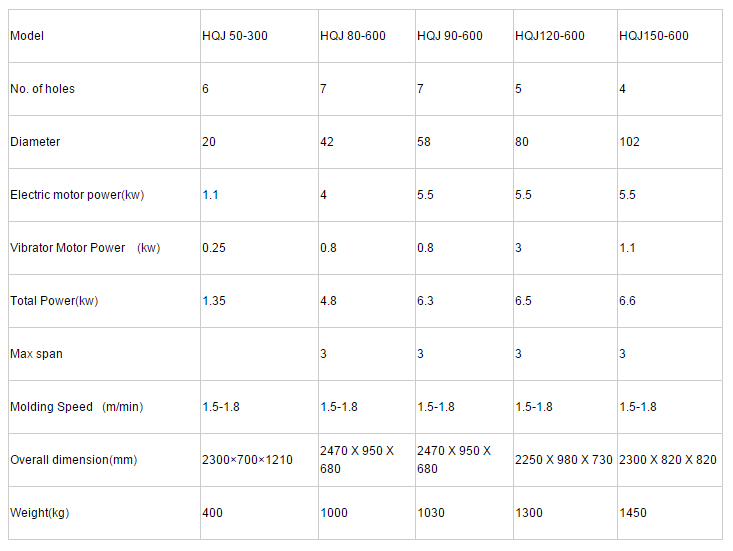

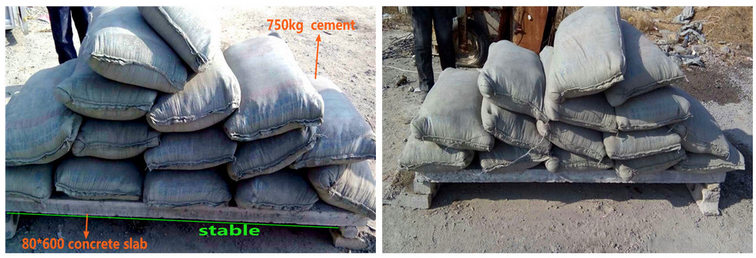

Quick Details

· Condition: New

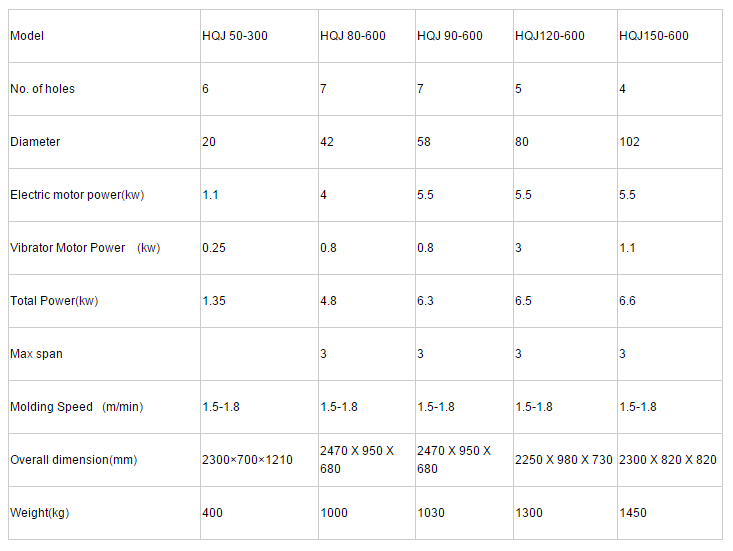

· Application: prefab building

· Automatic Grade: Automatic

· Production Capacity: 60-70m/h

· Place of Origin: Shandong, China (Mainland)

· Brand Name: LING FENG

· Model Number: SL80*600

· Voltage: 360v

· Power(W): 4.5-8.0kw

· Dimension(L*W*H): 2.5*1.0*1.0m

· Weight: 2.0T

· Features: high efficiency

· Certification: ISO9001/CE

· Warranty: 12 months

· After-sales Service Provided: Engineers available to service machinery overseas

· Main frame: 2.0*1.4m

· Color steel thickness: 0.3-0.8 mm

· Insulation: first class

· Shaft axis: diameter 80

· Brick Raw Material: Cement, sand, stone.

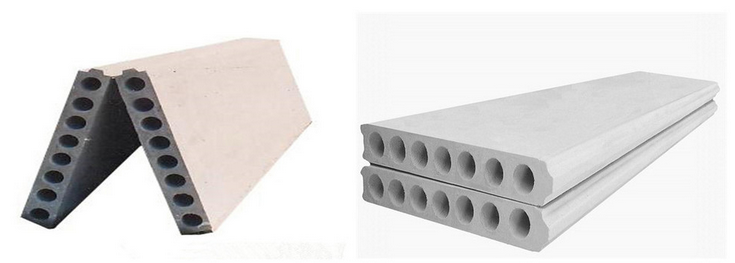

· Strength: water proof, fireproof, sound proof

· Vibrator type: ZW type 3.0kw

· Motor model: YEZ132S-4-B5

· Color: yellow or custom

· OEM: available

Products

Quality

Packaging & Delivery

Packaging Details: Wooden case and wood flour into the bottom of the box.

Delivery Detail: Within 15 days

Major Parts and advantage of lightweight wall panel machine

Features:

I. Anti-corrosion and wear-resistant.

The machine frame is made of manganese steel whose quality is better than normal steel. The interior side of the mould is made of stainless steel (its thickness can be 2.2mm) which can stand repeated use and corrosive materials. It can be used for over 10 years. Besides, panels made by this kind of machine have better quality than other kinds. The panel will not be deformed. Its surface is smoother than others.

II. High capacity

Normal hollow core wall panel machine can make only ten panels in one mould, but this machine can make 14 panels at one time.

III. Energy-saving

The machine uses storage battery as power which can save a lot of electricity and is safe to use. Besides, if there is something wrong with the machine in the production line, it will not influence the use of other machines.

IV. Lower the cost of production

We use stainless steel for the mould instead of traditional steel. Steel mould machines need brushing de-molding agent or the panels can't be taken out. Stainless steel machines need a little de-molding agent, this can save both labor and material cost for manufacturers.

V. Hydraulic mould closing and opening

The mould is opened and closed by hydraulic. Its moving is very smooth and stable. All the four sides of the mould can be opened together, so it is very easy to use and it can save labor and cost.

VI. Unique design

We have special design not only for the single machine, but also for the whole production line. Our mixer can be customized for the customer according to their requirement. We also have special equipment to get rid of the dust so that the production is very clean.

Our Services

Interests in the good faith, interests in quality, interests in the service

Customer visits and technical guidance provides 24-hour service and lifetime maintenance services, supply of spare parts. Site church consumer operation, teach operating essentials, equipment maintenance and production experience, considerations.

Our factory can produce all kinds of equipment and prefabricated factory accessories according to customer demand.

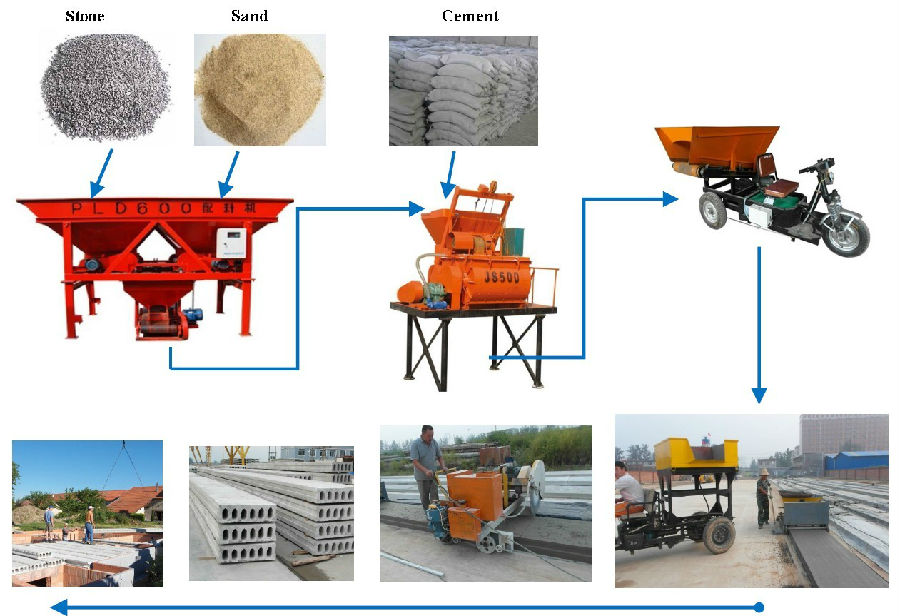

Flow chart:

Other available machines:

- Q:Thanks any help will doo.. i know it much be done by boat but i dont even know what to research or look up and what companies are there that could do this

- Google international cargo shipping or ocean freight forwarding in your area. Also you might want to ask around at the local seaport to find out who does business out of your region. Good luck!

- Q:I'm not sure what plant and machinery is and which is used in schools, any answers will be very helpful.

- Schools, Hospital and etc are non-profit motive institutions: so there is no chance for plant machinery

- Q:If the opportunity cost of manufacturing machinery is lower in the United States than in Britain and the opportunity cost of manufacturing sweaters is higher in the United States than in Britain, then the United States will: A. export both sweaters and machinery to Britain. B. import both sweaters and machinery from Britain. C. export sweaters to Britain and import machinery from Britain. D. import sweaters from Britain and export machinery to Britain.

- D. import sweaters from Britain and export machinery to Britain.

- Q:I work at a pizza place, and while washing dishes, a cheese grater fell off the shelf and broke. A piece that is important to the cheese grater's functioning. Now, mind you, it fell off the shelf and I was not touching it. My manager wants me to either pay cash, or he will just deduct it from my check, when I argued with him that it is a cost of doing business.Is this legal, and what sound I do?

- illegal. he can fire you, but may not deduct from your wages.

- Q:give me some examples of formal english text of how to apply?

- Gentlemen:/ I am considering expanding my business and using your compo nay as a supplier. Please send me without charge the following information: (Name the catalogs) Quotes on the following machinery: (List model Numbers) Thank you. Sincerely, John Doe President

- Q:What human can create a planet or life itself? But why do humans have creations of designed machinery ?

- Every time you make a choice you create at least two universes. every writer creates a living world and by reading, hearing or watching you get to live there for a while. If you never had that experience I both feel sorry for you and envy you because the chances are very good that someday you will for the first time and after that it will always be cool but never as great as the first time.

- Q:why is it important to reduce friction during the operation of machinery?

- So that there isn't any work wasted on overcoming the friction. It increases the efficiency of the machinery and its overall output

- Q:If I took off the machinery cover off my AK-47 rifle and I was to insert a loaded 30 round clip in the magazine well. And I was to pull back the charging handle, aim at the target, and then pull the trigger. Will it be a safe thing to do? Or will I get hurt?

- Actually yes. The only purpose it serves it has is to keep dust out. Plus maybe some help with the aesthetics.

- Q:Machinery poll: Exactly what job does a piledriver accomplish?

- great old school wrestling move....oh wait and helps me last a little longer than other ...ahem positions

- Q:Which companies provide them with their machinery to build the cars? I'm doing research and need to know these companies.

- The auto companies use many companies all over the world to develop those production lines. For example, a friend of mine in NJ has a small company that creates production lines for all kinds of companies. He recently developed a machine for one of the auto companies. That machine's sole job is to make the latch for the glove compartment. So, as you can imagine, there are probably hundreds of different companies invlolved.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete hollow wallpanel machine HQJ150-600

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords