Compression Spring, Heavy Duty, with Stainless Steel

- Loading Port:

- Nansha

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 151000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Heavy Duty Compression Spring:

1) Easily adjusted in coil diameter and pitch

2) Major materials: music wire, stainless

Features:

1) Easily adjusted in coil diameter and pitch

2) Major materials: music wire, stainless steel wire, oil tempered wire, spring steel

3) Different wire diameters, such as Ø4.0mm, 5.0mm, 8.0mm and 12.0mm

4) We possess a whole set of CNC manufacturing and testing equipment ranging from

wire tensile strength tester, shot peering machine, deburring machine, magnetic

powder flaw detector and compression tester

heavy duty compression springs

What kind of shape compression spring we can do for you?

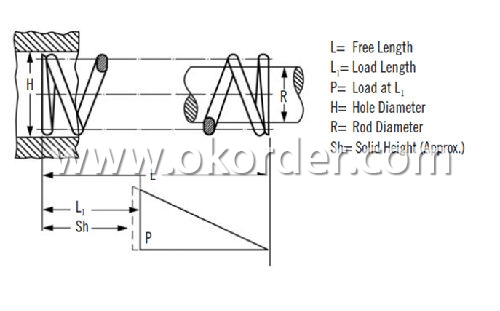

Spring shape: Conical, Round and Rectangular, Hourglass, Barrel, Constant Pitch, Variable Pitch etc. see picture below

•Product Information | |

| product name | Heavy Duty Piston Compression Spring |

| brand name | YD |

| model number | YD009 |

| certificate | ISO9001,RHOS |

| material | carbon steel,alloy spring steel,music wire steel,and stainless steel,iron,plated steel,alloy steel,bronze,red bronze,phosphor copper,and beryllium copper;etc |

| usage | car,all kinds of machines,motor,etc. |

| galvanized | nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated and so on or as your request |

| package | all springs will be carefully packed and shipped to you with PE bags. |

| payment | TT/LC |

| shipment | all orders are dispatched within 7-10 business days by EMS, DHL or as your request after making payment.A Tracking Number will be sent to you via e-mail after your order has been shipped.If you do not receive the Tracking Number email within 7 business days of confirming payment, please check your spam folder and then contact us. |

| PLEASE NOTE: Please allow 5-9 business days for your shipment to arrive. | |

Applications of Heavy Duty Compression Spring

Our packaging workshop of Springs

- Q:Want to practice how to use pectoral muscle spring expander

- If your strength is not enough, a chest start even more difficult, not easy to do it.It is recommended that you should not rely solely on the chest muscle training, according to their ability, to start from the first push ups. Practice to a certain extent to practice chest.If possible, the best way is to do chest push arms parallel flexion, but more difficult.The best chest group 20, a group is appropriate.

- Q:What kind of spring has the best performance?

- Spring verticality, verticality is bad, will directly affect the strength and life.

- Q:How to distinguish between spring steel and stainless steel

- Mainly depends on the performance of spring steel, good elasticity, stainless steel toughness. The color should be slightly white stainless steel. Spring steel is easy to rust, with a little salt a day you can see the stainless steel does not rust.

- Q:In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

- In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

- Q:How to process Spring Steel

- Spring steel must pay special attention to decarburization and surface quality during rolling. When the steel surface is seriously decarburization, the fatigue limit of steel will be significantly reduced. For high silicon spring steels, such as 70Si3MnA, caution shall be taken to avoid graphitization. Therefore, stop rolling temperature in hot working time should not be too low (less than 850 DEG C), avoid in the temperature range of graphite is easy to form (650 to 800 DEG C) in the long residence time.

- Q:How to choose spring steel material?

- In determining the cross-section shape and size of spring materials, priority should be given to rejection of the national standards or ministerial standards for size specifications, as far as possible to avoid the use of non-standard specifications of materials. Although the spiral spring square or rectangular cross section material, the elastic deformation can be higher than, can make the small volume of the spring, for spring, in small space or under impact load but because of square or rectangular section material shortage, the price is higher, and the spring forming is difficult, so should be avoided. Ring section spring material diameter series see table 3-9.

- Q:The shop glass spring door is too tight, how to adjust?

- If it is the glass door of the ground spring, then call the installation worker to loosen it.

- Q:What are the main functions of spring?

- Measure the magnitude of forces, such as springs, scales, and springs in a dynamometer

- Q:Buffer spring buffer for automobile

- Next, put a soapy water or lubricant on the loose coil spring. Then, insert a strong buffer of soap, water or lubricant into the loose spiral spring gap, and then release the car body after confirming it.Finally, the distance between the damping springs is a matter of concern for mounting the shock absorber. The distance between the springs is equal to the length of the shock absorber. If it is more difficult to squeeze by hand, loosen the screw of the shock absorber, and let the damping spring relax 2 - 3 centimeters.

- Q:Cold rolled coil spring spring and difference "

- Coil is to burn the red, generally large diameter to coil

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 10 Million - US$ 50 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America |

| Company Certifications | ISO 9001:2000 ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 60% - 80% |

| No.of Employees in Trade Department | 301 - 500 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | above 2000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Compression Spring, Heavy Duty, with Stainless Steel

- Loading Port:

- Nansha

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 151000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords