Compound Base/fiberglass Nonwoven Mat/composite Non Woven Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 45 roll

- Supply Capability:

- 12000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

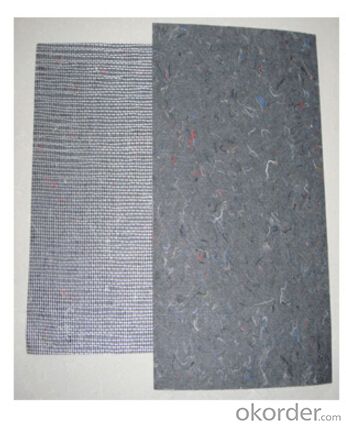

Product introduction

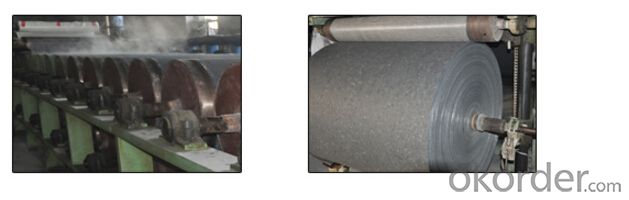

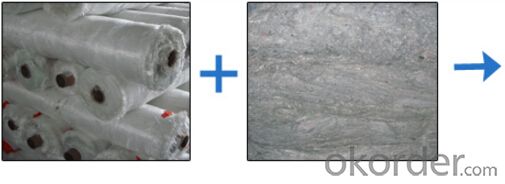

Glass fiber mesh composite mat for bitumen membrane is two layers composited non woven fabric. The top layer is fiberglass mesh reinforcement layer and the bottom layer is cotton non woven mat, Through high temperature, stoving, finalizing the design. It is a kind of reinforcement combination material.

It is characterized as high tensile strength, easy soakage by bitumen, low cost and so on.

1.width: 98cm/99cm/1m or as customers requirement

2.weight: 60-140g/m2

3.mesh size: 4*4-7*7

4.weave type: twill woven

5.yarn type: C-Glass

6.alkali content: medium

7.length of roll: 1000-3000m (the length can loaded more in container and save freight fee)

It is used for making changed SBS waterproof material, and for waterproof

in the underground, building roofing, ground and pond. combination fabric is base cloth

of using SBS waterproof material, its tension of warp and weft is more than 600N.

Among waterproof materials, this kind of product is the best favorable.

Glass fiber combination non woven is made on the base of non woven by compositing

some density glass fibre, through high temperature, stoving, finalizing the design. It is a

kind of reinforcement combination material.

packing: shrank wrapped each roll and put in pallet.

Non Stick It can easily remove all kinds of adhesives such as resin, paint and chemical medicine,easy to clean.

Chemical resistance--It can resist all most of chemical medicines

Permeability--It can avoid wasting heat and improve drying efficiency for it's permeability.

Technicial data

Item | Area Weight | Mesh | Tensile Strength | Shrinkage (230°C) | Roll Size | Loading Quantity | |

MD | CMD | ||||||

Unit | g/m2 | N/5cm | N/5cm | % | m x m | M2/40FCL | |

Specification | 90g | 4X4 | 350 | 250 | <1.0 | 1.0 x 1400 | 159600 |

100g | 5X5 | 400 | 200 | <1.0 | 1.0 x 1300 | 148200 | |

110g | 5X5 | 500 | 450 | <1.0 | 1.0 x 1250 | 142500 | |

120g-A | 6X6 | 550 | 350 | <1.0 | 1.0 x 1200 | 136800 | |

120g-B | 6X6 | 550 | 430 | <1.0 | 1.0 x 1200 | 136800 | |

130g | 7X7 | 600 | 500 | <1.0 | 1.0 x 1150 | 131100 | |

140g-S | 8X8 | 700 | 600 | <1.0 | 1.0 x 1100 | 125400 | |

Product show

FAQ

Q: Do you have your own factory?

Yes ,we have,and we have lived and developed for decade years.

Q: What are your main products?

We focus on Industrial pumps, Conveyor belts &conveyor machines, Hydraulic construction machines, water proofing materials& production lines and Plastic recycling machines.

Q: What makes you think your products are better than others?

We have advanced production equipment, strong technical force and strict quality testing methods.

Q: How can I make the order?

Q: Can you accept OEM service?

YES, just let me know the exact request on the products.

- Q:Waterproof electrode, waterproof welding

- 2, start welding should be in the vicinity of the weld without water at the arc. After the arc short arc quickly arc to the weld, with the arc to withstand some of the overflow. In the edge of the weld to form a pool after the arc immediately lead to the steel, the two sides together and gradually welded up. Under normal circumstances should be continuous arc, once the welding stopped, the tip of the electrode will not be able to lead the original arc

- Q:What is the impact of TPO waterproofing membrane welding performance?

- Dow Chemical TPO and Basel TPO due to the different grades of production technology, raw material ratio is different from the formula system for the performance of the material melting point, polymerization, molecular weight distribution index, melt index, melt strength, weldability are not same. It is recommended that attention be given to the above factors in the course of the test

- Q:Surfacing isolation layer is the application of what, how to achieve surfacing isolation layer weld.

- In order to maximize the role of the surfacing layer, the desired surfacing method has a smaller base metal dilution, higher welding speed and excellent surfacing performance, ie high quality, high efficiency, low dilution of the surfacing technology.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Compound Base/fiberglass Nonwoven Mat/composite Non Woven Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 45 roll

- Supply Capability:

- 12000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords