Composite Plastic Outdoor Decking /Plastic Decking/Environmantally Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wood Plastic Composite Decking- Hollow Decking

1.Description of Composit Decking

1.Item:RMD-53

2.Sizes: 140*25mm, 150*25mm, 225*30mm, 135*27mm, 120*25mm, 160*25mm, 100*25mm, 295*24mm,also we can make us customer request.

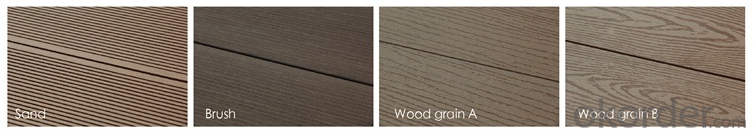

2.Surface Treatment of Composit Decking: smooth, sanded, brushed, wood grain

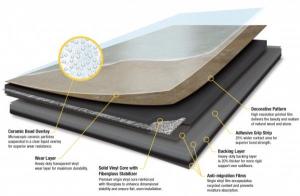

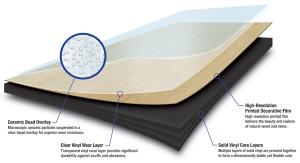

3. Component of Composit Decking

50% wood fibers + 40% HDPE + 10% chemical additives

4.Color of Composit Decking

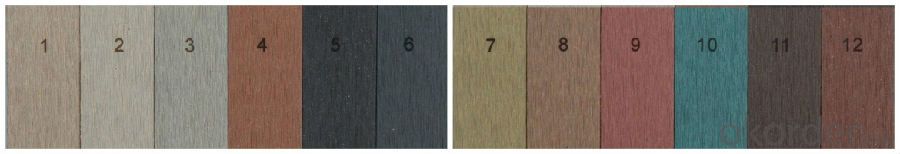

Black, coffee, brown, gray, redwood and more

5.Production of Composit Decking

6.Application of Composit Decking

Courtyard, Villa garden ,Private yard,Roof ,Balcony ,Dock,Swinning pool

Garden,Lawn,Balcony,Corridor,Garage, Pool and Spa Surrounds,Boardwalk,Playground

7.Features of Composit Decking

·Looks and feels natural wood

·Eco-friendly, high-recyclable, green material

·No cracking, warping and splitting

·Water/moisture-proof, corrosion-resistant

·Low maintenance and no painting

·Easy to install, clean

·Weather-resistant, suitable from -40 ℃to 60℃

·High degree of UV and color stability

Certificate by CE ,SGS,ISO, INTERTEK

Warranty 5 years!

Free Samples are Available!!

- Q:What is the name of the plastic floor on the supermarket, where is it?

- Plastic flooring selection coil special PVC glue, stairs, wall with adhesive

- Q:Is it suitable for plastic floor? What's the harm?Is it suitable for plastic floor? What's the harm? Please specify. With price

- Since the plastic floor can go to the public life, it shows that it has its own unique advantages:1 elastic, comfortable, can give people a warm feeling;2 surface into the UV treatment, pollution resistance, easy to clean;

- Q:The home is all ceramic tile or plastic floor

- It is not necessary, the general plastic floor for the warehouse floor, fire and less dust

- Q:How to clean plastic floor

- The plastic floor is widely used in all kinds of sports places, such as plastic floor, plastic field, plastic basketball court and plastic runway, etc.. Plastic floor itself has a long life, but if you want to extend its life, you need a long-term cleaning and maintenance plan. Cleaning the plastic floor of the tools and materials needed are: washing machine, nylon brush plate, suction machine, mop and bucket, etc.. Need to use the agent as a weak alkaline or neutral detergent.

- Q:How to remove the plastic tiles on the floor tiles

- Do not recommend the use of 84 disinfectant or banana water and other corrosive liquids, not only may burn the surface of the ceramic tile, but also make the surface color, on the health of the body will have a certain impact.

- Q:Such as the title, do not know what is the real wood floor shop? The following is the keel I am looking for the materials and the advantages and disadvantages, we have what opinions and suggestions might as well talk about... 4, keel laid the keel: many materials, the most traditional is also plastic, wood keel, wooden keel and so on Aluminum Alloy 1): on the ground drill, fixed wooden keel, wooden keel on surface leveling the floor with a nail, will start...Home renovation renovation of the old house, the living room plus two bedroom only 41 square meters, which is more suitable for...In addition, the room is small, the shop is too thin and good-looking and consumption of materials, want to shop 455*90*1.8 or 455*120*1.8

- Home is home renovation, so could not live for a long time, suggested the use of wooden keel, more environmentally friendly, but in which you want to add pepper and aniseed and lime mothproof, decadent

- Q:How to tear off the plastic film on the floor tiles

- Your turn is above if the plastic film may be the glass ceramics, finished directly to tear it, but to pay attention to, if it is microcrystalline stone, the surface of the glass is not scratch, when used to pay attention to, iron furniture must be wrapped, lest scratch, once scratch, there is no way to fix.

- Q:Ijiali will be on the floor of the kind of plastic that is connected to a piece of letters, animal patterns, such as the name of what ah

- The ground cushion treasure is a new type of light plate which is extruded by polystyrene resin and other additives. The utility model has a continuous uniform and dense surface layer and a closed cell structure, and the wall of the honeycomb structure has the same thickness.

- Q:Can the plastic stair step of the cement in the home spread the plastic floor

- Depends on the smoothness of the stairs, if the surface has a lot of pit pit bag is not installed directly

- Q:I asked about the "plastic" floor tile paving method, please describe its steps?

- Key tiles is flat ground, otherwise very easy to open or damaged floor brick. There are a lot of glue to the ground plate, can choose their own. Shop paste must be from the center to the surrounding, and some of the glue scraping after the need to be static 1 ~ 2 minutes after use. After sticking, the glue in the seam should be wiped off

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Composite Plastic Outdoor Decking /Plastic Decking/Environmantally Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords