Composite Panel Hot Press/Moulded Door Skin Hot Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Composite Panel Hot Press/Moulded Door Skin Hot Press

Descriptions:

NYJ-800T to 1600T composite panel hot press/moulded door skin hot press suitable for moulding and veneering of melamine door skin,natural wood door skin.Composite panel hot press/moulded door skin hot press adopts spring synchronous closed structure, can stop at any position according to the production preocess(or position-limit control), and the residence time can be adjusted. Composite panel hot press/moulded door skin hot press holding time and pressure set automatic control. Two operaing mode(manual and automatic) are convenient for customers to choose.

Features:

1. Control system: PLC control with connection to computer (Mitsubishi, Omron, Siemens optional), from infeed to storage,complete lamination offered. This system is stable and is of high automation. Technical parameters can be set, modified andmonitored by human-machine interface.

2. Mechanical system : Stable, easy to operate, high efficient and easy for maintenance.

3. Hydraulic system: Top branded valves and pumps are used for this system, with features of high stability, low noise, and no leakage.

Technical parameters of Composite panel hot press/moulded door skin hot press:

| Type | Finished Board Size(ft) | Nominal Pressure(KN) | Hot Pressboard Size(mm) | Layer Spacing(mm) | Main Oil cylinder(diameter×number) | |

| NYJ-800T | 3layer | 3×7 | 8000 | 1150×2250×70 | 250 | Φ440×920×4 |

| 4layer | 3×7 | 8000 | 1150×2250×60 | 250 | Φ250×1000×8 | |

| 5layer | 3×7 | 8000 | 1150×2250×60 | 250 | Φ280×1250×6 | |

| NYJ-1200T | 3layer | 3×7 | 12000 | 1150×2250×70 | 300 | Φ320×920×6 |

| 4×8 | 1400×2600×70 | |||||

| 4layer | 3×7 | 12000 | 1150×2250×60 | 250 | Φ320×1000×6 | |

| 4×8 | 1150×2250×60 | |||||

| 5layer | 3×7 | 12000 | 1150×2600×60 | 250 | Φ280×1250×8 | |

| 4×8 | 1400×2600×60 | |||||

| NYJ-1400T | 3layer | 3×7 | 14000 | 1150×2250×70 | 300 | Φ340×920×6 |

| 4×8 | 1400×2600×70 | |||||

| 4layer | 3×7 | 14000 | 1150×2250×60 | 250 | Φ340×1000×6 | |

| 4×8 | 1400×2600×60 | |||||

| 5layer | 3×7 | 14000 | 1150×2250×60 | 250 | Φ440×1250×6 | |

| 4×8 | 1400×2660×60 | |||||

| NYJ-1600T | 3layer | 4×8 | 16000 | 1400×2600×70 | 250 | Φ380×920×6 |

| 4layer | 4×8 | 16000 | 1400×2600×60 | 250 | Φ380×1000×6 | |

| 5layer | 4×8 | 16000 | 1400×2600×60 | 250 | Φ380×1250×6 | |

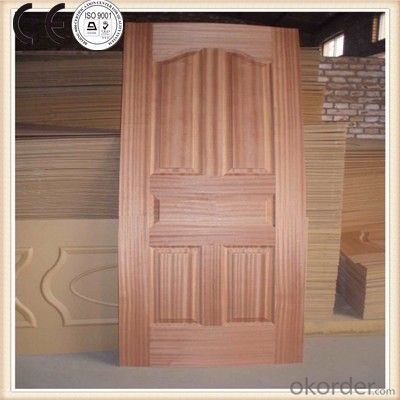

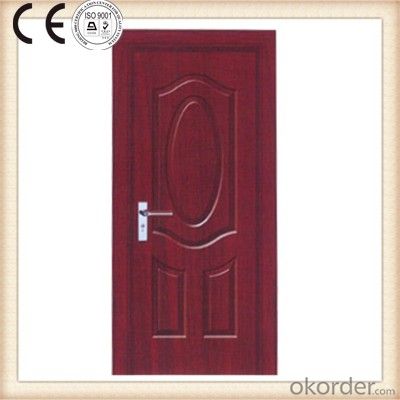

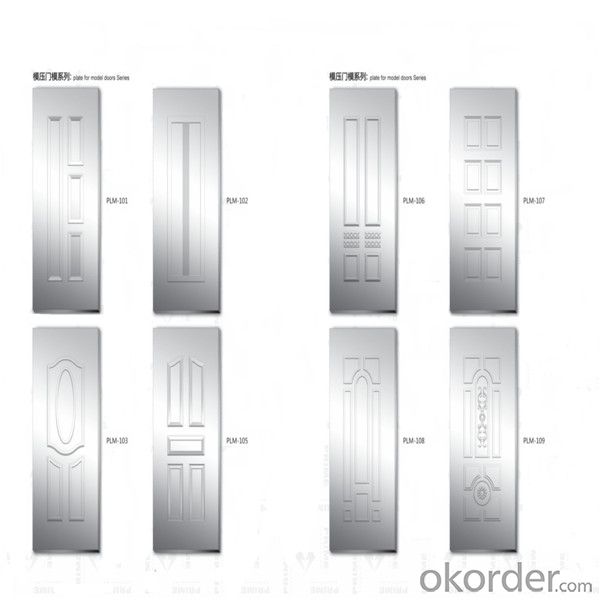

Composite panel hot press/moulded door skin hot press picture:

Door skin moulds:

Our certification

Package:Composite panel hot press/moulded door skin hot press will be packed according international wood door skin press machine standard packing

Our Factory

FAQ

Q:Where is your factory located? How can I visit there?

A:Our factory is located in Wuxi, Jiangsu Province, China, about one hours train from Shanghai . All our clients, from home or abroad, are warmly welcome to visit us!

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. We has gained ZDHY, ISO9001 authentication.

- Q:I love Lancome Photogenic pressed powder, but hate the $28 price tag. I do not usually wear any foundation, so the powder is all I use all day, everyday. Can anyone recommend a pressed powder very similar to this with a lower price? Thank you!

- arbonne's about face translucent pressed powder(16$) or about face loose powder(22$)

- Q:What's the difference, if any, between cold-pressed and first cold-pressed. Is there a difference??

- The first pressing is the best oil all the way down the line. They keep pressing for more and more oil. The better the quality, the higher the price and rarely used for cooking. Used mainly for drizzling over the finished meal or in a bowl to dip your fresh crusty bread into.

- Q:people are always saying that and it makes no sense, i think that you should say sign an affidavit or file charges someone explain to me how to press a charge

- If you think you are the victim of a criminal offense you do this: Go to the police and make a report. Write out and sign a sworn statement or complaint. The police will investigate and speak with the state attorney. If Probable Cause exists, they offender will be arrested or an Arrest Warrant will be issued for them. Once arrested, the state attorney will file a formal charge called an Information. The person will then be arraigned and scheduled for trial. Prior to trial, the offender will be offered plea deals. They either take it or go to trial. At trial, they are either found guilty or not guilty. If found guilty the judge will sentence them according to sentencing guidelines in your state for the crime committed.

- Q:Can I use ground espresso in a French press coffee maker?Would this be too strong? Would it make a mess?

- No, you can't. Here's why: 1) That fine of a grind will over extract be bitter. Larger chunks require longer for the flavors to release (20-30seconds for espresso vs 3-4 minutes for french press) 2) If you read the instructions included with a french press they warn against using too fine a grind. The reason isn't that it will get through the filter; it's that the grounds will clog the filter. If that happens, you won't be able to easily depress the plunger and the pressure may send scalding bitter coffee all over the place ( you).

- Q:does the leg press help w/ getting bigger glutes or is it only for legs?just want the effects of a rounder and more firm rearend and cant do squats.

- Yeah okorder /..

- Q:And how old are you and weight? i'm just curious

- bench 200, im 16 weigh 180, not sure about the others

- Q:just curious becuause im been working on my biceps lately and yes i see an improve just wondering if it also would help my bench press

- No. Bench press uses your chest and triceps. Biceps are not used. The best way to improve your bench press is by doing bench presses. Do 3 sets, 4 to 6 reps per set. If you can do more than 6 reps, increase the weight. If you can't do 4 reps, lower the weight. Do this 3 days a week, each time trying to do 1 extra rep than the last time, or 5 extra pounds than the last time.

- Q:alright people..i only want serious answers. my hair is naturally curly, not kinky. the only thing i need to do to get it straight is blowdry and maybe flat iron, so i never had to 'press' it. but now my younger sister is living with me,and i can not afford to take her to the salon all the time. so i will be responsible in taking care of her hair. she wears a press and curl, and she doesn't wear any other styles. my question is how do you press hair? help please!

- first start by sectioning off the hair in fours. Apply a little hair dressing to the hair, but not too much where you can hear it sizzle while pressing it. Place the comb on the stove and let sit for 3 to 4 minutes. Get a cloth and place the comb on it. It smokes too much or leave a burn mark on the cloth it's too hot to run through the hair. Start at the back, closest to the neck part hair and start at the roots and run the comb through slowly, also use the smooth side of the comb. Each time wipe the comb off before placing back on the stove and when removing it from the stove. Work up to the top, then do the other side the same way. Then doing the sides, start near the ear, have her hold a wooden spoon over her ears so it won't accidentally get burn( and then she will never want her pressed again), then start up going towards the top, then do the hairline last.

- Q:What were some impacts of the printing press and changes?I just need a list like1.something something something2.something something something3.something something somethingits for an essay but i will do the research I just need some starts!

- The printing press was invented by Gutenberg arround 1440. 1) It encouraged people to learn to read and a rise in literacy resulted. 2) Vernacular languages increased which allowed people of a poorer education to be able to buy and understand books. 3) The printing of the Bible in vernacular led to self-interpretation and more criticism of priests (eventually led to religious reform).

- Q:I want a ten inch flour tortilla press without a non-stick surface because non stick surfaces impart chemicals into the food. All the ones I've seen do. Suggestions?

- older presses are not non stick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Composite Panel Hot Press/Moulded Door Skin Hot Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products