Composite Geotextile Drainage for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Composite Geotextiles Drainage for Architectural Engineering

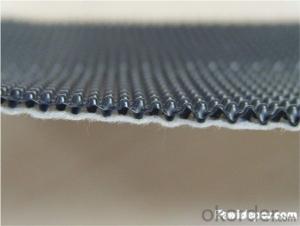

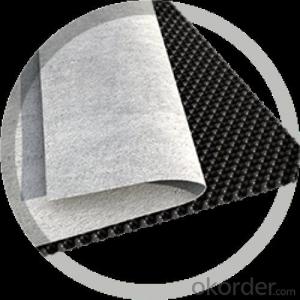

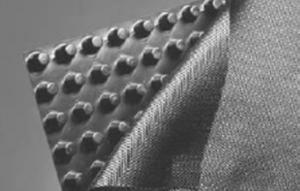

Description Of Composite Geotextiles Drainage for Architectural Engineering

Composite Geotextiles Drainage is a general term for the synthetic materials used in civil engineering. As a kind of civil engineering materials, it is to synthetic polymers, such as plastics, chemical fiber, synthetic rubber as raw material, made of various types of products, placed inside the soil, surface, or various kinds of soil play to strengthen or to protect the soil. The application of the technology of soil engineering synthetic materials will be divided into the type of the material of the soil, the soil, the soil, the special material and the composite.

Main Features of Composite Geotextiles Drainage for Architectural Engineering

The advantages of the composite is that the weight is light, and the overall continuity is good, construction is convenient, high tensile strength, corrosion resistance and resistance to microorganisms. The disadvantage is that, without special treatment, anti ultraviolet ability, such as exposure to ultraviolet radiation, is easy to aging, but if not directly exposed, the anti aging and durability performance is still high.

Applications of Composite Geotextiles Drainage for Architectural Engineering

1, used to bear the weight of the embankment and shallow water treatment.

2, used to prevent the landslide and the load of the gravity of the hybrid retaining wall.

IMages of Composite Geotextiles Drainage for Architectural Engineering

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q:On the Title of Civil Engineering

- one. No, two Influence, three, to the unit for your registration

- Q:What are the different surface patterns available for earthwork products?

- Some of the different surface patterns available for earthwork products include smooth, textured, ribbed, stamped, and imprinted patterns.

- Q:Can earthwork products be used for culvert construction?

- Yes, earthwork products can be used for culvert construction. Earthwork products such as compacted soil, gravel, and geotextiles are commonly used in culvert construction to provide stability, drainage, and erosion control. These materials can be used to create a solid foundation and backfill around the culvert, ensuring proper function and longevity of the structure.

- Q:What are the key properties to consider when selecting geosynthetic materials for earthwork?

- When selecting geosynthetic materials for earthwork, it is important to consider key properties such as strength, durability, permeability, and compatibility with the surrounding soil and environment. Strength ensures the material can withstand the loads and stresses imposed on it during construction and throughout its service life. Durability ensures the material can resist degradation from exposure to UV radiation, chemicals, and physical abrasion. Permeability determines the material's ability to allow water and gas flow through it, preventing accumulation and potential damage. Compatibility with the surrounding soil and environment ensures that the material will not react negatively with the soil or surrounding materials, maintaining the desired performance and preventing any adverse effects.

- Q:How do earthwork products help with noise reduction?

- Earthwork products help with noise reduction by acting as barriers or sound absorbers. For example, using earthen berms or mounds as a natural sound barrier can help to block or deflect noise, minimizing its impact on surrounding areas. Additionally, materials like soil, gravel, or vegetation can absorb sound waves, reducing their intensity and creating a quieter environment.

- Q:Can earthwork products be used in agricultural applications?

- Yes, earthwork products can be used in agricultural applications. Earthwork products such as soil, gravel, and mulch can be used to enhance soil quality, control erosion, improve drainage, and create raised beds or pathways in agricultural settings.

- Q:Why civil engineering to solve the problem is to give full play to the role of materials

- Cost-effective, with its own things have their price Well High-end material performance is good, the same high price, if the project does need this high-end materials to meet the construction requirements, it can only use this, because the general material will cause engineering quality problems. However, if the general performance requirements, that is, ordinary materials can be resolved, then use ordinary materials like, without the need for high-end materials, which can save costs.

- Q:How can geosynthetic panels be used in canal lining projects?

- Geosynthetic panels can be used in canal lining projects as an effective means of erosion control and water containment. These panels are typically made of synthetic materials such as geotextiles or geomembranes, which provide a protective barrier against seepage and erosion. By installing these panels along the canal's banks and bottom, they help to prevent water loss, minimize soil erosion, and improve overall water management. Additionally, geosynthetic panels are easy to install and maintain, making them a cost-effective solution for canal lining projects.

- Q:What are the advantages of using geosynthetic materials in groundwater recharge projects?

- There are several advantages of using geosynthetic materials in groundwater recharge projects. Firstly, geosynthetics can act as a barrier, preventing the loss of water during the recharge process. They have a high permeability, allowing water to pass through while retaining fine particles and preventing clogging of the recharge system. Additionally, geosynthetics can provide structural stability to the recharge system, preventing erosion and maintaining the integrity of the project over time. Moreover, these materials are durable and resistant to degradation, ensuring long-term effectiveness and reducing the need for frequent maintenance. Overall, the use of geosynthetics in groundwater recharge projects can enhance efficiency, reliability, and sustainability of water resources management.

- Q:How do earthwork products contribute to land remediation and restoration?

- Earthwork products, such as soil, clay, and gravel, play a crucial role in land remediation and restoration. These products are used to address various issues, including soil contamination, erosion, and land degradation. By importing or redistributing these materials, earthwork products can help restore the natural balance of the land, improve soil quality, and stabilize slopes. Additionally, these products can be used in the construction of wetlands, reforestation projects, and other ecosystem restoration efforts, promoting biodiversity and enhancing the overall health of the land.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Composite Geotextile Drainage for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords