Composit Decking for Outdoor Wall Panel/WPC Flooring/120*30/RMD-53

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wood Plastic Composite Decking- Hollow Decking

1.Description of Composit Decking for Outdoor Wall Panel

1.Item:RMD-53

2.Sizes: 140*25mm, 150*25mm, 225*30mm, 135*27mm, 120*25mm, 160*25mm, 100*25mm, 295*24mm,also we can make us customer request.

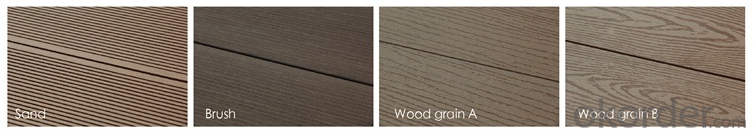

2.Surface Treatment of Composit Decking for Outdoor Wall Panel: smooth, sanded, brushed, wood grain

3. Component of Composit Decking for Outdoor Wall Panel

50% wood fibers + 40% HDPE + 10% chemical additives

4.Color of Composit Decking for Outdoor Wall Panel

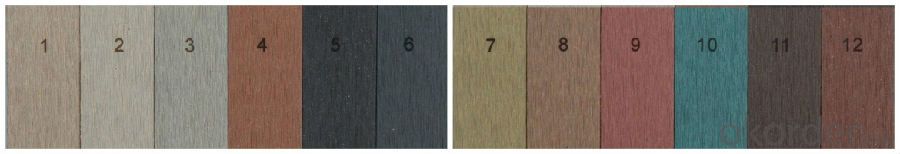

Black, coffee, brown, gray, redwood and more

5.Production of Composit Decking for Outdoor Wall Panel

6.Application of Composit Decking for Outdoor Wall Panel

Courtyard, Villa garden ,Private yard,Roof ,Balcony ,Dock,Swinning pool

Garden,Lawn,Balcony,Corridor,Garage, Pool and Spa Surrounds,Boardwalk,Playground

7.Features of Composit Decking for Outdoor Wall Panel ·Looks and feels natural wood

·Eco-friendly, high-recyclable, green material

·No cracking, warping and splitting

·Water/moisture-proof, corrosion-resistant

·Low maintenance and no painting

·Easy to install, clean

·Weather-resistant, suitable from -40 ℃to 60℃

·High degree of UV and color stability

Certificate by CE ,SGS,ISO, INTERTEK

Warranty 5 years!

Free Samples are Available!!

- Q:How to eliminate the smell of plastic floor

- No special way to remove the taste is the plastic floor itself distributed, you shop this must be afraid of children playing on the ground fall

- Q:How to shop plastic floor?

- The first floor sheet ground floor flat on the ground, more than 8 meters distance laying the floor shall be divided into two period of laying.

- Q:Home decoration, floor requirements should be very flat

- Hello, like now is winter, low temperature period should pay special attention to prevent the occurrence of bad construction measures

- Q:What is the plastic floor, what is the plastic floor

- Plastic floor according to its basic raw materials can be divided into polyvinyl chloride (PVC) plastic, polyethylene (PE) plastic and polypropylene (PP) plastics, etc.. Because PVC has good resistance to combustion and self extinguishing, coupled with its performance can be changed by changing the amount of plasticizer and filler to add, so the current PVC plastic floor is the most widely used.

- Q:What is the plastic floor?

- 3.0mm (mm), the scope of application: family room, hotels, restaurants, airports, schools, hospitals, clinics, light industrial factories, offices, offices, laboratories, shopping malls, entertainment, etc. all kinds of cylindrical wall and ground of indoor space, grade quality, special purpose: wear pattern: wood material.: PVC. Product features: vidon material compared with traditional materials, stone plastic floor model as an alternative to products from the function and purpose has its irreplaceable advantages: A, rich colors, easy splicing,.... Manufacturer of plastic floor is Suzhou Zhaoshun Trade Co. Ltd., plastic floor brand: vidon, specifications: place of origin: Taiwan, wandon, specifications: 178mm brand:

- Q:PVC plastic floor construction costs a square meter

- Our office is a very good use of Gerflor 170 a square meter construction costs

- Q:Home decoration with plastic floor, please? What are its strengths and weaknesses?

- Plastic floor has many advantages,:Elastic, comfortable, can give people a warm feeling; 2 surface in UV processing, pollution resistant, easy to clean; 3 green environmental protection, does not contain formaldehyde, inhibit the growth of bacteria; 4 case of water stains, good skid resistance,

- Q:What is the role of the floor mat plastic sheeting

- You should say that it is a composite floor, his role is mainly moisture, as well as the role of leveling

- Q:How can a lot of plastic cloth stick on the wood floor?

- Because the general protective film is a good tear in a certain period of time, more than the time to protect the film because it is difficult to tear the oxidation. Hope to help you!

- Q:What is the difference between PVC plastic floor and graphite plastic floor

- Plastic floor is another name for PVC flooring. The main component of PVC material, PVC floor can be made into two kinds, one is homogeneous, is from the bottom to the pattern material is the same. There is a composite type, is the top layer is a pure PVC transparent layer, the following with the printing layer and foam layer. "PVC floor" refers to the use of polyvinyl chloride material production floor. Specifically to the polyvinyl chloride and its copolymerization resin as the main raw material, filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet substrate, the coating process or by rolling or extrusion process and. (1) the form is divided into 2 floors and the floor sheet sheet; the floor sheet is more soft texture of the rolls of the floor, the width is 1.5 meters, 1.83 meters, 2 meters, 3 meters, 4 meters, 5 meters, the length of each volume is 7.5 meters, 15 meters, 20 meters, 25 meters, the total thickness of 1.6mm-3.2mm (only commercial flooring, sports flooring thickness of up to 4mm, 5mm, 6mm etc.). The specifications of the sheet flooring are mainly divided into strip and square.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Composit Decking for Outdoor Wall Panel/WPC Flooring/120*30/RMD-53

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords