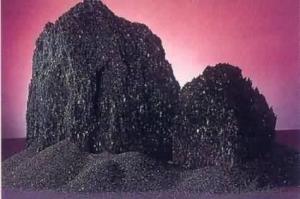

Competitive Price Export Carborundum, Silicon Carbide, Black SiC , Silicon Carbide Alloy Powder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | CBNM | Model Number: | SiC98.5, SiC,98 SiC97, SiC95, SiC90 |

| Application: | Steelmaking & Casting | Shape: | irregular block | Material: | SiC |

| Dimensions: | SiC lump | Chemical Composition: | SiC, Free Carbon, Fe2O3 | color: | black gray |

Packaging & Delivery

| Packaging Details: | 1000 kg plastic woven bag |

| Delivery Detail: | two weeks after making order |

Product Description

Silicon carbide (SiC) is using quartz sand and petroleum coke or coal tar, wood chips (green silicon carbide production need to add salt) such as raw material through high temperature electric resistance furnace smelting.There is also a rare mineral silicon carbide in nature, and the mo SangShi. Silicon carbide is also called the moissanite. In contemporary C, N, B the oxide refractory raw materials in the high technology, such as silicon carbide as the most widely used, one of the most economic, can be called corundum or refractory sand.At present China's industrial production of silicon carbide can be divided into two black silicon carbide and green silicon carbide.

Product grades and chemical composition:

Product grades | Chemical composition(%) | ||

SiC | Free Carbon | Fe2O3 | |

SiC 98.5 | 98.5 min | 0.2 max | 0.6 max |

SiC 98 | 98 min | 0.3max | 0.8 max |

SiC 97 | 97 min | 0.3 max | 1.0 max |

SiC 95 | 97 min | 0.4 max | 1.0 max |

SiC 90 | 97 min | 0.6 max | 1.2 max |

Note: Our company can adjust production according to client’s requirements of other brand of chemical composition and granularity.

Product Effects

Reusable abrasive:

1. Lapping and polishing medium

2. Grinding wheels and grinding medium

3. ear-resistant and refractory products

Blasting systems:

1. Pressure blast systems

2. Injection blast cabinets

Packaging and Delivery

1. Regular products packing with 1000 kg composite woven bags outside for each ton.

2. Special product package with moisture barrier bag.

3. Package with customers' requirement, single packing also can be adjusted according to the size of converter molten pool.

- Q:What refractory materials are used in power plant

- And then I will introduce some application of thermal material in power plant (below) I hope I can help you. Energy saving is the trend of future industrial development efforts, grinding machine, conveyor belt, so the production of light thermal insulation materials will gain state support, drying kiln. Our factory mainly produce light thermal insulation brick. The refractory material we use most is light insulation brick, and the equipment used is sand mixer (Luohe, Henan)

- Q:how does the fire endurance of first rate fire resistant window?

- class A window not less than 1.5 hours, class B window not less than 1 hours, Class C window not less than 0.5 hours.

- Q:What is the difference in the nature between the refractory material and thermal?insulation?material

- thermal?insulation?material is a material which has a strong impedance to the heat flow. the nature of the material requires that the material can isolate the delivery of thermal, and the low heat conductivity coefficient and expansion coefficient of the non-metal material.refractory is good in heat resisitance and chamical erosion but not high temperature resistance. Requirements on nature is still in high temperature.

- Q:What's the definition of fire endurance of the fire-resistant coating for steel structure?

- 1. Fire endurance. Conduct fire resistance test of any building component according to the standard time-temperature curve, and the time when it is subjected to the fire to the time when it loses support capability or fire insulation function or its integrality is destroyed is referred to fire endurance. 2. Steel has relatively low fire endurance which is usually 0.25h only, namely 15 minutes; 3. Of steel structure buildings, steel can be used as beams, pillars, etc. but its fire endurance is not enough (usually these components have higher requirement on fire endurance, and take pillar as an example, it is usually demanded that the fire endurance should be 2-3h), and under this condition, it needs to brush fire retardant coating so as to raise the fire endurance. As to the specific quantity or types of the fire retardant coating, it is decided upon the actual conditions. In short, the building material needs to meet the required fire endurance of the buildings.

- Q:Fire insulation and fireproof insulation board materials What is the difference in performance?

- What is the difference between fireproof insulation board and fireproof materials in their performance? Fireproof Materials prevents burning through insulating while others by chemical reactions. The overall heat conductivity coefficient of Insulation materials are generally lowered by thermal conductivity of the material itself and the structure of the material. Inorganic active insulation material uses ordinary cement, insulation stone, calcium powder, platycodon grandiflorum as the main raw material, produced after numerous tests with advanced production technology and chemical technology. Products features fire retardant,anti-aging properties and stable performance, low deformation coefficient, environmentaly friendly, compatible with the wall base layer and plastering layer. It has good security and stability and is as durable as ordinary buildings. Strong fire resistance: Fire insulation board is made of inorganic materials (cement), fireproofing level reaching to A1. As it does not burn, it is fireproof.

- Q:What are the specifications of refractory kilns ?

- Since the coefficient of thermal expansion of the basic brick is large, expansion rate is about 1-1.2% under 1000 ℃ The literature indicates that: "Under the condition that the temperature was raised to 1000 ℃ and stress in brick lining is relaxed, 300N / mm2 of compressive stress can be produced, which is equals to ten times structural strength of ordinary magnesia chrome brick, six times structural strength of magnesia chrome brick, dolomite brick and spinel brick, so any basic bricks can not afford, " the paper also pointed out that " heat expansion rate of kiln body can partially compensate for expansion rate of the inner lining of 0.2% -0.4%, which is 1/3 of thermal expansion rate of ordinary magnesia-chrome brick under 1000 ℃. However, it occurs under thermal equilibrium conditions. Thereby, the kiln should be dried slowly, allowing the temperature of the kiln body to go up slowly, thus the role of compensation can be played. " This is the key to using the basic brick. " Procedures of refractory for cement kiln "( tentative one) has clearly regulated baking and cooling of the kiln in the first section of the fifth chapters. In the heating process, in particular when the temperature is in the range of 300-1000 ℃, heating rate must be less than 60 ℃ / h. This is very clear in theory but it is difficult to implement.

- Q:Can anyone say something about the curtain wall fire-proof material key sealing point?

- When sealing the gaps between glass?curtain?wall and floors of all layers and the outer edge of the partition with rock wool or mineral wool, its thickness should not be less than 100mm and should be filled densely; Rock wool or mineral wool for horizontal smoke prevention zone between floors should use galvanized steel sheet whose thickness is not less than 1.5mm to support; The gaps between supporting plate, major structure, curtain wall structure and supporting plate should be filled with fire-resistant glass, whose fire endurance should meet the design requirements. Fire-resistant glass for curtain wall are mainly include monolithic fire-resistant glass as well as the hollow glass and laminated glass made by monolithic fire-resistant glass.

- Q:I am a refractory material manufacturer, sold products, money is always not back, anxious to die, what is the way?

- Metallurgical industry downturn. There is fierce competition in the refractory industry.

- Q:I know which material is the fire resistance rolling shutter door

- the materials of fire resistance rolling shutter door are: the inner of fire resistance rolling shutter door is generally filled with aluminum silicate fiber cotton. fire resistance rolling shutter door is divided into AAA inorganic fireproof rolling shutter door and steel fire resistance rolling shutter door. the fireproof?performance of inorganic fireproof rolling shutter door is better, but steel fire resistance rolling shutter door has a certain wind load resistance, which can be installed outdoors.

- Q:Does anyone know the characteristics of refractory for glass kiln?

- Quartzitic sandstone. Also known as quartzitic sandstone or white gravel. Which is a kind of natural refractory and quartz sandstone bonded by the kaolinite. Who appearance is better to be steel-grey, dense and hard, free of impurities and stripes. Its main crystalline phase is mainly quartz and kaolinite. Which has obvious stratified structure and anisotropism. The refractoriness fluctuation is between 1650~1730 ℃. The expansibility of quartzitic sandstone is different from that of silica?brick, who has maximum coefficient of thermal expansion under temperatures of 700 ~ 800 ℃, and it is most likely to burst at this time. The load softening temperature and the compression strength of calcined quartzitic sandstone have been improved significantly, with small residual expansion, stable volume, better thermal shock resistance, so it is generally to use calcinated quartzitic sandstone as refractories. which has been widely used as sidewall blocks on the small and medium sized furnaces.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Competitive Price Export Carborundum, Silicon Carbide, Black SiC , Silicon Carbide Alloy Powder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords