Commercial Plywood with High Quality for 15mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

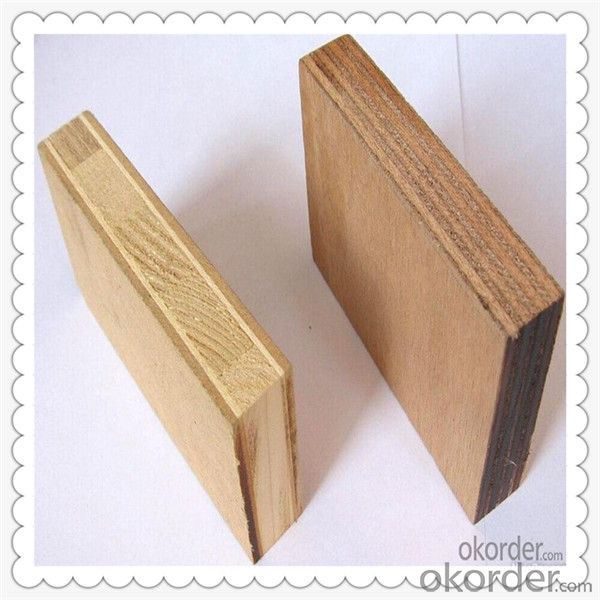

Commercial Plywood with High Quality for 15mm Thickness

Product Description:

· Type: Plywood

· Material: Wood

· Panel Type: Commercial Plywood

· Use: Outdoor

· Place of Origin: China (Mainland)

· Model Number: 1220x2440mm

· Material: Poplar Material

· Thickness: 3mm to 21mm

Packaging & Delivery:

1. Packaging Details: inner packing:0.20mm plastic bag; outer packing: pallets are covered with plywood or carton and then steel for strength

2. Delivery Detail: within 15 days after receiving the deposit

Product Specification:

Detailed Product Description | ||

Features | Face/back | melamine /veneer/pvc/hpl/ev (As you required) |

Glue | E1 or E2 ... (As you please) | |

Size | 1220*2440mm or 1830*2440mm | |

Thickness | 2.0mm~35mm | |

Core | poplar, combi etc. | |

Moisture | normal, moisture-proof, water-proof, eco-friendly | |

Payment & Shipping | MOQ | 1*20' container (negotiable) |

Port | Qingdao | |

Packing details | Inter packing: 0.20mm plastic bag Outer packing: pallets are covered with plywood or carton and then steel for strength | |

Delivery time | Within 15~20 days after 30% deposit or L/C | |

Payment terms | L/C,T/T | |

Supply ability | 50*40' HQ per Month | |

Advantages | Guarantee of 2 years | |

Competitive price | ||

ECO- friendly—— E1 grade, CARB P2 certificated | ||

High quality and excellent workmanship | ||

Company Info:

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q:Fuhan 18mmE0 grade sandwich panels how?

- Now are generally E1-class wood core board, and E1 grade Fuhan plate genuine goods, then environmental protection is the standard. E0 level of rare, and expensive

- Q:Color steel sandwich board board how to deal with bump

- Raw material quality is not good, after forming a bad treatment

- Q:Rock wool sandwich board how, what are the advantages?

- Compared to the foam sandwich panel, he fire, strength better. Compared to polyurethane sandwich panels, he is cheap, fireproof It is more resistant to heat than glass wool Compared to the hollow glass magnesium board, his thermal performance is good But there is a certain amount of dust Now if you want to achieve the best results Rockwool Magnesium is your best choice

- Q:Do the wardrobe with a wooden sandwich board or solid wood particle board is good

- I have seen more with the wooden sandwich panels, more beautiful, feel better

- Q:What are the benefits of color steel?

- First, the advantages of color-type steel plate envelope The color of the pressure-type steel plate is the surface of the chemical treatment and double-sided color coated with thin steel plate by rolling cold forming sheet, is a good performance of light, high strength, Beautiful modern building materials. Color plate used in color plate characteristics: (1) the coating has a high strength of the adhesive; (b) the coating has excellent damage to the machinability; (c) does not change the color does not crack good weather resistance (D) strong corrosion resistance; (5) flame retardant; (f) rich and beautiful color does not fade; (7) coating surface easy to wash. These features give the color plate has brought many excellent features. Plant with color plate for the envelope structure and other materials commonly used in China's envelope compared to the following advantages: (a) flexible layout, can be determined according to the needs of the process span, column spacing, unlike the reinforced concrete prefabricated components (2) section design has more choices, the roof length and slope of the limitations of small, can be set a variety of skylights, choose a variety of lighting methods; (c) facade rich and colorful, pleasant color, (4) factory production, high efficiency; (5) light weight, construction and installation of simple, change the towing water for the clean and tidy of the construction of the situation, the construction of the production of high-quality, Construction speed; (6) easy to replace the maintenance, easy to plant expansion. Color plate can also be used for civil construction, with color plate envelope structure of civil construction is unique, especially for large space stadiums, exhibition halls and other public buildings, it is more superior.

- Q:Color steel tile foam sandwich board model is how the classification

- Common sandwich panels: foam sandwich panels, rock wool sandwich panels, polyurethane sandwich panels. Common specifications: roof board 980, wall board 950. Common thickness: 50mm, 75mm, 100m.

- Q:Hard polyurethane sandwich board combustion performance?

- In general, the ordinary hard polyurethane sandwich board combustion performance is very good, it depends on how you treat this problem. Requirements are high or low are the main reasons for quality

- Q:What is the difference between a steel plate sandwich board?

- Pressure plate also known as wave plate, the general is the use of color coated steel plate, the cold bending into a variety of wave-type pressure plate. Sandwich panels, also known as composite panels, the color coated steel or other panels and the bottom plate and insulation core material through the adhesive (or foam) compound ?????????????????? Into the insulation composite sheet. The simplest difference is that the pressure plate is a veneer sandwich panel is a composite board

- Q:What are the thickness of the color steel sandwich board? Color steel sandwich panels: two layers of steel thickness of 0.6mm, the middle folder a layer of foam, a total thickness of several specifications?

- Color steel sandwich panel thickness generally have the following: 25mm 50mm 75mm 100mm 150mm 200mm which after the two kinds of thickness is generally used for cold storage. You said the foam (EPS) density of the points, generally: 4g 6g 8g 10g, Can be purchased according to their own needs!

- Q:The steel roof and the sandwich panel are waterproof

- The two are actually the same class of things, sandwich panels only the color plate and insulation layer together, the installation more convenient. And the pressure steel roof need to lay another insulation layer and the roof. For both, the weak links of water are between the plates. In the actual project, the seam of the steel plate roof can be made in many forms, some of the overlapping form of waterproof performance is very good, and the common sandwich board roof shape is relatively simple, so the waterproof performance is also worse.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Commercial Plywood with High Quality for 15mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords