Column Steel Billet 3SP 5SP 20MnSi for Stoves Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

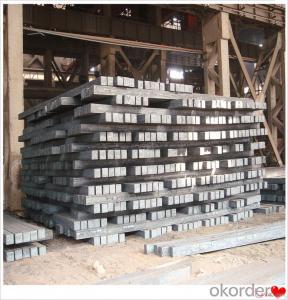

Column Steel Billet 3SP 5SP 20MnSi for Stoves Steel Billet

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q:What are steel billets?

- Steel billets are semi-finished metal products that are rectangular in shape and usually have a square cross-section. They are produced through a process called casting or continuous casting, where liquid steel is poured into molds and allowed to cool and solidify. Once cooled, the billets are typically hot-rolled or forged to give them their final shape and dimensions. Steel billets serve as a raw material for the production of various steel products, such as bars, rods, wires, and structural sections. They are commonly used in the construction industry for structural purposes, as well as in the manufacturing of automotive parts, pipes, and machinery. The quality of steel billets is crucial, as it directly affects the quality and performance of the final steel products. Therefore, they undergo rigorous quality checks and testing to ensure they meet the required standards for strength, durability, and other mechanical properties. Overall, steel billets play a vital role in the steel industry as a primary raw material for the production of a wide range of steel products, making them an essential component in various sectors of the economy.

- Q:How do steel billets contribute to the infrastructure development sector?

- Steel billets play a crucial role in the infrastructure development sector by serving as the foundation for various construction projects. These billets are used to produce structural steel products, such as beams, columns, and reinforcement bars, which are essential components in building bridges, highways, buildings, and other infrastructure projects. The strength and durability of steel billets make them ideal for withstanding heavy loads and adverse weather conditions, ensuring the long-term stability and safety of structures. Moreover, their versatility allows for easy fabrication and customization, enabling engineers and architects to design innovative and efficient solutions for infrastructure development. Overall, steel billets provide the necessary strength, reliability, and flexibility to support the growth and sustainability of the infrastructure development sector.

- Q:Which is good for pure iron billet?

- Stainless steel, pure iron, military pure iron and industrial pure iron products have to choose the enterprises of good quality and excellent after-sale service. These problems must be taken into consideration in the process of purchasing.

- Q:How are steel billets inspected for hardness?

- Steel billets are inspected for hardness using a non-destructive testing method called ultrasonic testing. This involves the use of high-frequency sound waves that are transmitted through the billet. The reflected sound waves are then analyzed to determine the hardness of the steel. This method allows for accurate and reliable hardness inspection without causing any damage to the billet.

- Q:What are the different types of steel billet rolling defects?

- During the rolling process, various defects can arise in steel billets, which can have adverse effects on the final product's quality and integrity. The most commonly encountered types of steel billet rolling defects are as follows: 1. Surface cracks: These are minute cracks that manifest on the billet's surface. They can result from inadequate cooling or excessive rolling pressure. Surface cracks jeopardize the steel's strength and durability. 2. Center cracks: Inner core cracks occur when temperature control during the rolling process is incorrect. Center cracks can lead to structural weaknesses and reduced steel performance. 3. Scalloping: Scalloping refers to the formation of shallow depressions or grooves on the billet's surface. It usually arises due to uneven or improper rolling pressure distribution. Scalloping negatively impacts the steel's appearance and surface quality. 4. Lamination: Lamination defects involve the separation of layers within the billet. They can be caused by the presence of impurities or inclusions in the steel, as well as inadequate heating or rolling conditions. Lamination defects weaken the steel and increase the risk of failure. 5. Wavy edges: Wavy edges occur when the billet's edges become uneven or distorted during rolling. This can be the result of improper alignment or uneven pressure distribution. Wavy edges affect the steel's dimensional accuracy and overall quality. 6. Surface defects: Surface defects encompass scratches, pits, or other imperfections on the billet's surface. They may occur due to insufficient cleaning or handling procedures, as well as improper rolling conditions. Surface defects impact the steel's appearance and surface quality. In conclusion, these steel billet rolling defects hold significant implications for the final product's quality, performance, and safety. Manufacturers must closely monitor the rolling process and implement appropriate quality control measures to minimize the occurrence of these defects.

- Q:How are steel billets stored and transported?

- Steel billets are typically stored outdoors in large yards or warehouses, where they are organized in stacks or rows. To protect them from corrosion, billets are often covered with tarpaulins or anti-rust coatings. When it comes to transportation, steel billets are usually moved using heavy machinery like cranes or forklifts. They are loaded onto trucks, railcars, or ships, depending on the distance to be traveled. To ensure safety during transport, billets are secured with chains, straps, or other fastening methods to prevent shifting or falling.

- Q:Is the reaction of carbon and carbon dioxide a redox reaction?

- The reaction of carbon and carbon dioxide is redox reaction.Turn left and turn right |Oxidation reduction reaction is a kind of reaction that changes the number of oxidation of elements before and after chemical reaction. The essence of redox reaction is the gain or loss of electrons or the offset of common electron pairs. The oxidation number of the element changes before and after the redox reaction.

- Q:What are the main factors that determine the sustainability of steel billets production?

- The main factors that determine the sustainability of steel billets production include the source of raw materials, energy efficiency in the production process, waste management, carbon emissions, water usage, and adherence to environmental regulations. Additionally, the implementation of sustainable practices such as recycling, reducing greenhouse gas emissions, and promoting responsible sourcing contribute to the overall sustainability of steel billets production.

- Q:What are the potential applications of steel billets in the aerospace aftermarket?

- The aerospace aftermarket offers a wide range of potential applications for steel billets. These applications encompass the production of various aerospace components, including engine parts, airframe structures, landing gear components, and fasteners. One possible use of steel billets in the aerospace aftermarket is for manufacturing engine parts. Critical components like turbine blades, compressor discs, and shafts can be produced using steel billets. These parts require high strength, durability, and resistance to extreme temperatures, all of which can be achieved through the utilization of steel billets. Additionally, steel billets can be employed to manufacture exhaust system components like manifolds and flanges, which also require high temperature resistance. Another significant application of steel billets in the aerospace aftermarket is in the production of airframe structures. Steel billets can be utilized to manufacture various structural components, including beams, frames, and brackets. These components are essential for providing strength and stability to the aircraft's fuselage, wings, and other structural elements. Steel billets offer the necessary strength-to-weight ratio, corrosion resistance, and fatigue resistance required for these demanding applications. Furthermore, steel billets have the potential to be used in the production of landing gear components in the aerospace aftermarket. Landing gear plays a critical role in the safe operation of an aircraft, and it must withstand significant loads and stresses during takeoff, landing, and taxiing. Steel billets can be machined into landing gear parts such as axles, struts, and wheels, which require high strength, toughness, and fatigue resistance. Lastly, steel billets find applications in the production of fasteners used in the aerospace aftermarket. Essential for joining various components together in an aircraft, fasteners such as bolts, screws, and nuts are vital for secure connections. Steel billets can be forged or machined into high-strength fasteners capable of withstanding the high loads and vibrations experienced during flight. In summary, the aerospace aftermarket offers numerous potential applications for steel billets. From engine parts to airframe structures, landing gear components, and fasteners, steel billets provide the necessary properties required for the demanding aerospace industry, including strength, durability, temperature resistance, and fatigue resistance.

- Q:What is the role of steel billets in the manufacturing of automotive frames?

- Steel billets play a crucial role in the manufacturing of automotive frames as they serve as the raw material for forging or rolling processes. The billets are heated and shaped into desired forms, providing the necessary strength and durability to support the vehicle's structure. These frames are designed to withstand various forces, ensuring safety and stability on the road.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Column Steel Billet 3SP 5SP 20MnSi for Stoves Steel Billet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords