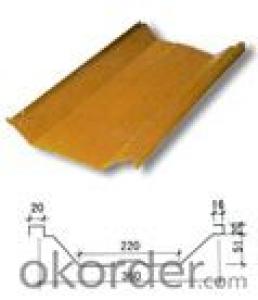

colored steel plate3

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | Grade: | Place of Origin: | |||

| Brand Name: | Model Number: | Type: | |||

| Technique: | Surface Treatment: | Application: | |||

| Material: | Certificate: | Design: | |||

| galvanized steel coil: | galvanized steel sheet: |

Packaging & Delivery

| Packaging Detail: | Naked package or loose package for steel structure |

| Delivery Detail: | According to customers' requirements & our actual producing pla n |

Specifications

price mild steel sheet:

1. Strong and reliable Galvanized Steel Sheet

2. Antiseismic

3.Meeting different requests

Commodity | price mild steel sheet |

Thickness: | 4mm-120mm |

Width | 1500mm-3600mm |

Length | Random length as your request |

Technique | Hot Rolled and Cold Rolled |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 SAE1010,SAE1020,SAE1045 |

Surface Treatment | Galvanized |

Application | Construction filed, ship building, chemical industry, food processing,etc. |

MOQ | 5 tons |

Supply Ability | 3000 tons |

Delivery | Within 7-15 days after confirmation |

Packaging | In standard export packing or as your request. |

Payment | L\C or T/T |

- Q:How much is 2 millimeters per square meter?

- The performance of carbon steel mainly has the following deficiencies:(1) hardenability is low. Under normal circumstances, the maximum quenching diameter of carbon steel water quenching is only 10mm-20mm.(2) strength and yield strength are relatively low, such as the s of ordinary carbon steel Q235 is 235MPa, while that of low alloy structural steel 16Mn is 360MPa and above s. The sigma S / sigma B of steel 40 is only 0.43, much lower than that of alloy steel.(3) the stability of tempering tempering stability, carbon steel in quenching and tempering treatment, in order to ensure the high strength with the tempering temperature is lower, so the toughness of the steel is lower; in order to ensure good toughness, with high tempering temperature strength is low, the mechanical properties of carbon steel level is not high.(4) stainless steel can not meet the requirements of special performance. Carbon steel is often poor in oxidation resistance, corrosion resistance, heat resistance, low temperature resistance, wear resistance and special electromagnetic properties, and can not meet the needs of special performance.

- Q:Can the steel sheets be used for decorative purposes?

- Yes, steel sheets can be used for decorative purposes. They can be cut, shaped, and finished in various ways to create unique and visually appealing designs for applications such as architectural features, wall cladding, furniture, and artwork.

- Q:Do steel sheets require any special storage or handling?

- Special storage and handling are required for steel sheets. To prevent corrosion and damage, it is crucial to store them in a dry and well-ventilated area, avoiding moisture buildup. Additionally, they should be kept away from direct sunlight and extreme temperature fluctuations to prevent warping or cracking. To prevent bending or sagging, steel sheets should be stored horizontally on a flat surface. Furthermore, it is advisable to stack them securely and appropriately, utilizing suitable supports or pallets, to prevent accidents or injuries. When handling steel sheets, proper lifting equipment and techniques should be employed to avoid injuries and sheet damage. Wearing gloves is essential to protect against sharp edges, and caution should be exercised to prevent contact with materials that may cause scratches or damage. Adhering to these storage and handling guidelines will ensure the durability and quality of steel sheets.

- Q:What is the difference between a self-color and painted steel sheet?

- A self-color steel sheet is one that has not undergone any additional surface treatment or coating, whereas a painted steel sheet has been coated with a layer of paint or another protective coating to enhance its appearance and provide added protection against corrosion or other environmental factors.

- Q:Can steel sheets be used for elevator manufacturing?

- Indeed, elevator manufacturing can involve the utilization of steel sheets. Owing to its robustness, endurance, and ability to withstand fire and corrosion, steel serves as a frequently employed substance in the construction of elevators. For the fabrication of elevator cabin walls, floors, and doors, steel sheets are commonly employed. In addition, steel finds application in the structural framework and support constituents of the elevator system. The inclusion of steel sheets in elevator manufacturing ensures steadfastness, security, and durability, rendering it a trustworthy option for vertical transportation.

- Q:What is the bending radius for steel sheets?

- The bending radius of steel sheets is influenced by several factors, including the sheet's thickness, the type of steel utilized, and the particular application at hand. Typically, a widely accepted guideline suggests employing a bending radius that is no less than twice the thickness of the steel sheet. Nevertheless, this figure can fluctuate depending on the specific demands and constraints of the undertaking. It is crucial to seek guidance from engineering and fabrication specialists experienced in handling steel sheets to ascertain the suitable bending radius for a specific application.

- Q:What are the common thicknesses for galvalume steel sheets?

- The common thicknesses for galvalume steel sheets typically range from 0.0149 inches to 0.0478 inches.

- Q:What are the different joining methods for steel sheets?

- There exist several methods for joining steel sheets, each with its own benefits and applications. 1. Welding, a widely used method, involves melting and fusing the sheet edges together with heat. Various welding techniques, such as arc, MIG, TIG, and spot welding, are available. Welding ensures robust and durable joints but demands skilled operators and can be time-consuming. 2. Bolting, another method, employs bolts or screws to connect steel sheets. This method is commonly preferred when disassembly or maintenance is necessary. Bolting guarantees strong and reliable joints, and it is relatively simple and quick. However, it may involve drilling holes and result in a less visually appealing appearance compared to welding. 3. Riveting, a method utilizing metal pins or rivets, effectively joins steel sheets. Rivets are inserted through pre-drilled holes and then deformed or expanded to secure them in place. Riveting ensures strong and secure joints, commonly used in applications requiring high shear strength. Nevertheless, it can be time-consuming and necessitates specialized tools and skills. 4. Adhesive bonding involves using specialized adhesives or bonding agents to join steel sheets. The adhesive is applied between the sheets and forms a strong bond as it cures. Adhesive bonding provides excellent aesthetics, leaving no visible joints, and evenly distributes stress across the joint. It finds common use in industries where welding or other methods are unsuitable, such as automotive and aerospace sectors. 5. Clinching utilizes mechanical force to join steel sheets. It entails deforming the sheet edges to interlock them and create a strong joint. Clinching is cost-effective as it does not require additional materials like fasteners or adhesives. However, it may not be suitable for applications requiring high load-bearing capacity. Ultimately, the choice of joining method for steel sheets depends on factors such as the application, desired strength, aesthetics, time constraints, and cost considerations. Each method possesses its own advantages and limitations, necessitating the selection of the most appropriate method for the specific project requirements.

- Q:Can steel sheets be used for mezzanine flooring?

- Indeed, mezzanine flooring can make use of steel sheets. Mezzanine flooring benefits from the numerous advantages provided by steel sheets, such as their strength, durability, and versatility. Steel sheets are capable of withstanding substantial loads and offer a dependable and stable solution for flooring needs. Moreover, they can be easily tailored to suit specific dimensions and requirements, making them adaptable for various mezzanine designs. Additionally, steel sheets exhibit resistance to fire, moisture, and pests, guaranteeing a flooring option that is long-lasting and requires minimal maintenance. In summary, due to their robustness, durability, and adaptability, steel sheets are a popular choice for mezzanine flooring.

- Q:How are steel sheets protected during storage in outdoor environments?

- Steel sheets are protected during storage in outdoor environments through the application of various protective measures. These measures may include the use of weather-resistant coatings, such as galvanization or paint, to prevent corrosion and rusting. Additionally, steel sheets can be stored on pallets or racks to minimize contact with the ground and reduce the risk of moisture accumulation. Covering the sheets with tarpaulins or using weatherproof storage containers further shields them from direct exposure to rain, snow, and sunlight. Regular inspections and maintenance are crucial to ensure the effectiveness of these protective measures and to address any potential issues promptly.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

colored steel plate3

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords