Color Stainless Steel 201/304/316 Mirror Finish Stainless Steel Sheet For Elevators

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

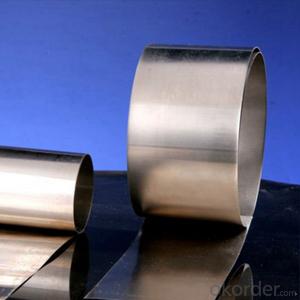

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q:Can stainless steel sheets be used for water filtration systems?

- Yes, stainless steel sheets can be used for water filtration systems. Stainless steel is commonly used in water filtration due to its excellent corrosion resistance and durability. It is able to withstand high pressure, temperature variations, and exposure to different chemicals, making it suitable for long-term use in water filtration applications. The smooth surface of stainless steel sheets also facilitates easy cleaning and prevents the accumulation of bacteria and other contaminants. Additionally, stainless steel is a non-reactive material, meaning it does not release any harmful substances into the filtered water, ensuring its safety for consumption. Overall, stainless steel sheets are a reliable and effective choice for water filtration systems.

- Q:What is the difference between stainless steel sheets and stainless steel plates?

- Stainless steel sheets and stainless steel plates are both commonly used in various industries and have similar properties, but they differ in terms of thickness and application. Stainless steel sheets are generally thinner than stainless steel plates. They are typically less than 6mm thick and are often used for decorative purposes, such as in kitchen appliances, automotive trim, and signage. Stainless steel sheets can also be easily bent or formed into different shapes, making them suitable for projects that require flexibility. On the other hand, stainless steel plates are thicker and more robust than sheets. They are typically more than 6mm thick and are commonly used in heavy-duty applications, such as construction, machinery, and industrial equipment. Stainless steel plates provide greater strength, durability, and resistance to corrosion, making them suitable for withstanding high temperatures, pressure, and mechanical stress. Another difference lies in the manufacturing process. Stainless steel sheets are usually produced by cold rolling or hot rolling, resulting in a smooth and flat surface. Stainless steel plates, on the other hand, are typically produced through hot rolling followed by heat treatment, which enhances their mechanical properties. In summary, while stainless steel sheets and stainless steel plates are both made of the same material, their thickness, application, and manufacturing process set them apart. Sheets are thinner and more flexible, primarily used for decorative purposes. Plates are thicker, stronger, and designed for heavy-duty applications that require greater strength and durability.

- Q:Are stainless steel sheets safe for medical applications?

- Yes, stainless steel sheets are safe for medical applications. They are widely used in the medical industry due to their excellent corrosion resistance, biocompatibility, and durability. Stainless steel is easy to clean, sterilize, and maintain, making it suitable for surgical instruments, medical devices, and equipment used in healthcare settings.

- Q:How do I install stainless steel sheets?

- To install stainless steel sheets, start by measuring and marking the area where the sheets will be installed. Next, ensure the surface is clean and free from dust or debris. Apply a strong adhesive or use screws to secure the sheets to the surface, making sure they are aligned properly. If needed, cut the sheets to fit using appropriate tools such as a metal shear or circular saw with a metal-cutting blade. Finally, ensure all edges and seams are properly sealed to prevent water or moisture infiltration.

- Q:Can stainless steel sheets be used for aerospace fasteners?

- Yes, stainless steel sheets can be used for aerospace fasteners. Stainless steel is a popular choice for aerospace applications due to its excellent corrosion resistance, high strength, and durability. It can withstand extreme temperatures and environments, making it suitable for use in aircraft components that are exposed to challenging conditions. Stainless steel sheets can be fabricated into various shapes and sizes to serve as fasteners such as screws, bolts, and rivets, providing a reliable and secure connection in aerospace structures. Additionally, stainless steel's non-magnetic properties are advantageous for certain aerospace applications where magnetic interference needs to be minimized. Overall, stainless steel sheets are a reliable and widely used material for aerospace fasteners.

- Q:Are stainless steel sheets suitable for architectural handrails or guardrails?

- Yes, stainless steel sheets are highly suitable for architectural handrails or guardrails. Stainless steel is a popular choice for these applications due to its excellent strength, durability, and corrosion resistance properties. It is able to withstand various weather conditions and is resistant to rust, making it ideal for outdoor installations. Stainless steel sheets can be easily customized and fabricated into different shapes and sizes, allowing for flexibility in design. Additionally, stainless steel has an aesthetic appeal that complements modern architectural designs. It is a low-maintenance material that requires minimal upkeep, making it a cost-effective choice in the long run. Overall, stainless steel sheets are a reliable and versatile option for architectural handrails or guardrails.

- Q:Can stainless steel sheets be used for lighting fixtures?

- Indeed, lighting fixtures can utilize stainless steel sheets. Stainless steel, a material renowned for its versatility and durability, finds wide application in numerous fields, including lighting fixtures. It boasts various advantages, such as resistance to corrosion, remarkable strength, and aesthetic allure. By employing stainless steel sheets, one can effortlessly mold, fabricate, and weld them to generate diverse lighting fixture designs and finishes. Furthermore, stainless steel's reflective surface heightens the lighting effect, ultimately creating an eye-catching and brilliantly illuminated atmosphere. Hence, due to their lastingness, adaptability, and aesthetic attributes, stainless steel sheets prove to be a fitting choice for lighting fixtures.

- Q:Are stainless steel sheets suitable for pharmaceutical cleanrooms?

- Yes, stainless steel sheets are highly suitable for pharmaceutical cleanrooms. Stainless steel is a preferred material in cleanroom environments due to its inherent qualities such as corrosion resistance, durability, and ease of cleaning. It is non-porous, making it resistant to bacteria, mold, and other contaminants. Additionally, stainless steel is able to withstand frequent sanitization procedures without deteriorating, making it a reliable choice for maintaining a clean and sterile environment in pharmaceutical cleanrooms.

- Q:Can stainless steel sheets be used in architectural designs?

- Yes, stainless steel sheets can definitely be used in architectural designs. Stainless steel is a versatile material that offers numerous benefits for architectural applications. It is known for its durability, corrosion resistance, and aesthetic appeal, making it a popular choice among architects and designers. Stainless steel sheets can be used in various architectural elements such as cladding, roofing, facades, and decorative features. The material's sleek and modern appearance adds a touch of elegance to any design, whether it's a residential building, commercial structure, or public space. One of the primary advantages of stainless steel sheets is their resistance to corrosion, which makes them suitable for both interior and exterior use. They can withstand harsh weather conditions, UV radiation, and pollutants, ensuring a long-lasting and low-maintenance solution for architectural projects. Additionally, stainless steel sheets are available in different finishes, including brushed, polished, and patterned, allowing architects to create unique and visually appealing designs. The material can be easily formed, welded, and fabricated into various shapes, enabling architects to achieve their desired architectural vision. Stainless steel sheets also offer excellent fire resistance, making them ideal for applications where safety is a priority. They are non-combustible and have a high melting point, providing added protection in case of fire. Furthermore, stainless steel is an environmentally friendly choice. It is 100% recyclable, with a high recycling rate, which reduces the need for new raw materials and helps minimize waste. In conclusion, stainless steel sheets are a versatile and durable material that can be used effectively in architectural designs. Their corrosion resistance, aesthetic appeal, fire resistance, and sustainability make them a popular choice among architects and designers for a wide range of applications.

- Q:Are stainless steel sheets resistant to organic acids?

- Stainless steel sheets, in general, have a resistance to organic acids. The corrosion resistance of stainless steel is well-known, and this quality extends to its ability to withstand the effects of organic acids. However, the level of resistance can vary depending on the specific composition of the stainless steel, as well as the concentration and type of organic acid being used. In certain cases, specific organic acids may cause localized corrosion or pitting on the surface of stainless steel. Nonetheless, stainless steel is considered a suitable material for handling organic acids in various industries like chemical processing, pharmaceuticals, and food production. To ensure the best resistance, it is always advisable to seek expert advice or refer to specific stainless steel grades and their compatibility with different organic acids.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Stainless Steel 201/304/316 Mirror Finish Stainless Steel Sheet For Elevators

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords