Color Prepainting Aluminium Coils for Outer Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

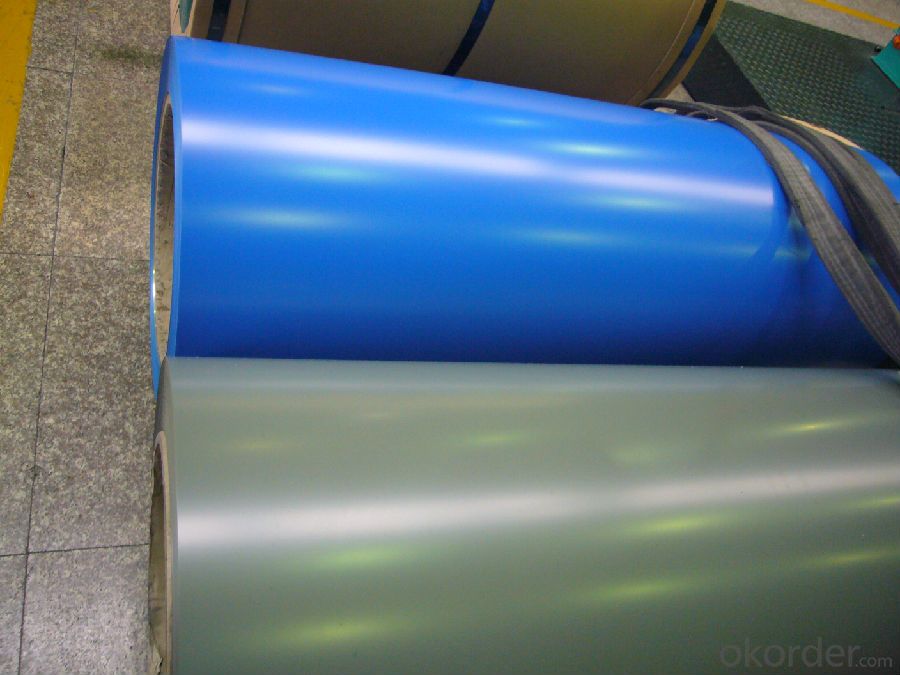

1.Structure of Color Prepainting Aluminium Coils for Outer Wall

Color Prepainting Aluminium Coils for Outer Wall is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Prepainting Aluminium Coils for Outer Wall

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | Temper | Coating Thickness | Coating | Weight |

| AA1050 | H14 | 20-25 MICRONS | PE | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:How do aluminum coils contribute to energy-efficient insulation?

- Aluminum coils contribute to energy-efficient insulation by serving as a barrier that prevents the transfer of heat. Due to aluminum's excellent thermal conductivity, it efficiently conducts and dissipates heat, reducing energy loss and improving insulation performance. Additionally, aluminum coils can be used in the construction of air conditioning and refrigeration systems, where they enhance energy efficiency by enabling better heat transfer and reducing energy consumption.

- Q:What are the potential applications of coil-annealed aluminum coils?

- Coil-annealed aluminum coils have a wide range of potential applications due to their unique properties. They can be used in manufacturing various products such as automotive parts, electronic components, packaging materials, construction materials, and even in the aerospace industry. The annealing process enhances the coil's flexibility, strength, and corrosion resistance, making it ideal for applications where durability, formability, and lightweight characteristics are crucial.

- Q:Can aluminum coils be used for automotive body panels?

- Yes, aluminum coils can indeed be used for automotive body panels. In fact, aluminum is becoming increasingly popular in the automotive industry due to its many advantages. Aluminum is lightweight, which can contribute to improved fuel efficiency and overall performance of the vehicle. Additionally, aluminum has excellent corrosion resistance properties, making it a durable choice for automotive body panels. Moreover, aluminum can be easily formed and molded, allowing for intricate designs and better aerodynamics. Overall, the use of aluminum coils for automotive body panels is a viable option that offers numerous benefits.

- Q:Are aluminum coils suitable for insulation purposes?

- Indeed, aluminum coils are well-suited for insulation purposes due to their exceptional heat and electricity conductivity. This quality makes them a perfect selection for insulation applications. Aluminum coils find utility in a wide range of uses such as HVAC systems, refrigeration units, and electrical wiring. Typically, these coils are coated with an insulating material like polyurethane foam or fiberglass to augment their insulation capabilities. The amalgamation of aluminum and insulation works wonders in impeding the transfer of heat or cold, thereby providing superb thermal insulation. Moreover, aluminum is lightweight, sturdy, and resistant to corrosion, rendering it a dependable choice for long-lasting insulation requirements.

- Q:Can aluminum coils be used in the production of aluminum composite walls?

- Yes, aluminum coils can be used in the production of aluminum composite walls. Aluminum coils are commonly used as a raw material in the manufacturing process of aluminum composite walls. These coils are typically processed to form flat sheets, which are then bonded to a core material to create the composite panel. The lightweight and durable nature of aluminum make it a suitable choice for constructing high-quality and aesthetically pleasing composite walls.

- Q:What are the different types of aluminum coils?

- There are several different types of aluminum coils available, each with its own unique properties and uses. Some common types include: 1. Plain Aluminum Coils: These coils are typically made from pure aluminum and are used in a variety of applications, including packaging, construction, and automotive industries. 2. Embossed Aluminum Coils: These coils have a textured or patterned surface, which adds aesthetic appeal and can enhance the grip or provide anti-slip properties. They are commonly used in architectural designs, signage, and decorative applications. 3. Color Coated Aluminum Coils: These coils have a protective coating applied to the surface, providing enhanced durability, weather resistance, and aesthetic customization. They are often used in building facades, roofing, and cladding systems. 4. Anodized Aluminum Coils: Anodization is an electrochemical process that forms a layer of oxide on the surface of the aluminum, making it more resistant to corrosion and wear. Anodized aluminum coils are commonly used in architectural applications, electronics, and automotive parts. 5. Pre-painted Aluminum Coils: These coils have a layer of paint applied to the surface, providing protection against weathering and adding color aesthetics. They are frequently used in the construction industry for roofing, siding, and insulation purposes. 6. Stucco Embossed Aluminum Coils: These coils have a raised pattern resembling stucco, which adds texture and enhances the strength of the aluminum. They are commonly used in refrigerators, air conditioners, and other appliances. 7. Clad Aluminum Coils: Clad aluminum coils consist of two or more layers of aluminum bonded together for enhanced strength, durability, or specific properties. They are used in various industries, such as aerospace, defense, and transportation. Overall, the choice of aluminum coil type depends on the specific application requirements, such as desired appearance, corrosion resistance, durability, and mechanical properties.

- Q:how tall is a crushed aluminium soda can compared to a non crushed one.i need measurements in centimeters please.ALSO!! AN IMAGE that actually has both of the two with the measurements would be SUPER HELPFUL

- I recognize that there are places in this world where aluminum beverage cans are very exotic, very rare, and may even be quite expensive. I can also understand that, in such a special place, one may have never actually held one of these objects in your own hands. If you live in such a place, then I can understand why you need to seek assistance on Yahoo Answers. I am, personally, quite surprised that you would have internet access in such a place. For your answer... it depends on how you crush the can but it is quite possible to crush your standard aluminum beverage can to a thickness of fractions of a centimeter.

- Q:Can aluminum coils be used in chemical processing equipment?

- Yes, aluminum coils can be used in chemical processing equipment. Aluminum is known for its corrosion resistance and high thermal conductivity, making it suitable for various chemical processing applications. However, it is important to consider the specific chemical and operating conditions to ensure compatibility and prevent any potential reactions or damage to the equipment.

- Q:Aluminum is a metal and nitrate (nitrogen) is a non metal so shouldn't they form an ionic bond and not a covalnt bond? And if it were an ionic bond wouldn't it be called aluminum mononitrate? But it is a covalnt bond (thus a molecular bond and so there is no mono in the name). Pleas help I'm very confused!

- You have the advantage here. As far as I know, the compound is ionic with one Al^+3 ion and three NO3^-1 ions. There have to be 3 negative ions to balance the charge of +3 on the aluminum ion to make a neutral formula unit

- Q:I am shopping for new Rollerblades and see their newer skates have Aluminum framesand not the composite which I feel is more sturdier. What do you think of the aluminumframes? I was not impressed.

- complicated matter. research on google. this can assist!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Prepainting Aluminium Coils for Outer Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords