Color Painted and Embossed Aluminium Foils Used for Insulated Panels

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Color Painted and Embossed Aluminium Foils Used for Insulated Panels

We professionally produce transparent color coated auminium foils used for insulated panel. Normally we use 1100 H22 as base coils and coated with clear epoxy, which is easily to be stuck with polyurathane and phenolic foam.

We have very strict inspection management including inspection for materials, inspection during production and inspection for finished goods.

Our test equipments include optical thickness gauge, cupping test machine, mettle Toledo, tensile-strength tester, busting strength tester, elongation tester, etc.

2.Main Features of Color Painted and Embossed Aluminium Foils Used for Insulated Panels

Moisture resistant

Light and easy for installation

Heat preservation

Low thermal conductivity

Durable and corrosion resistance

High heat reflection

Energy Saving

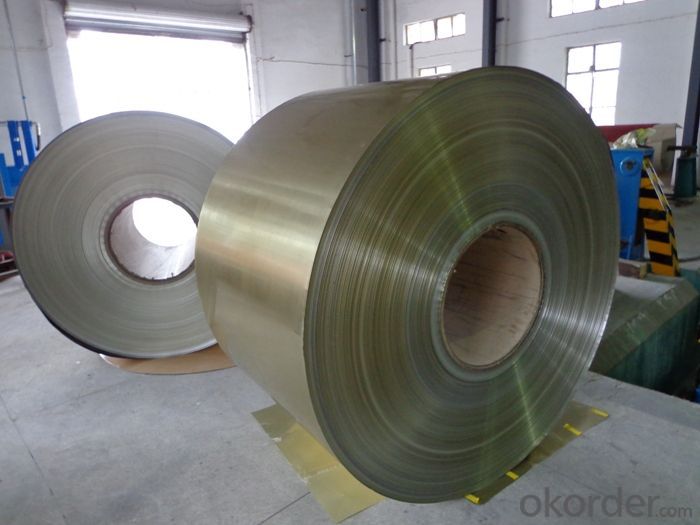

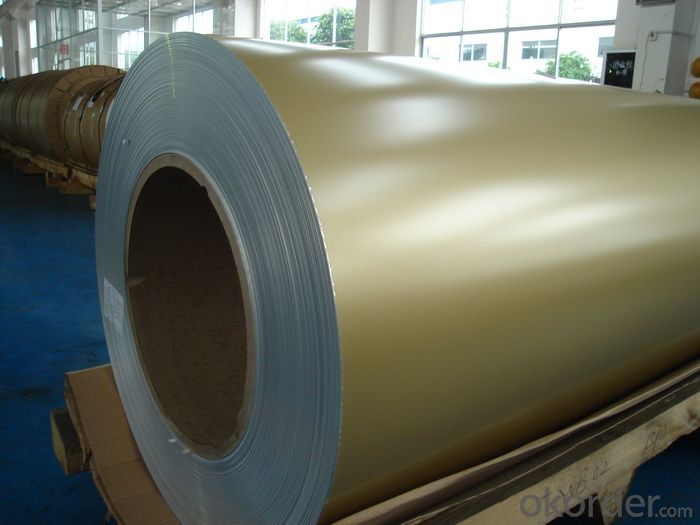

3. Color Painted and Embossed Aluminium Foils Used for Insulated Panels Images

4.Specification of Color Painted and Embossed Aluminium Foils Used for Insulated Panels

Alloy: 8011/ 1100/ 1235

Temper: O/H18/H22/H24/H26

Thickness & tolerance: 0.007-0.2mm (+/-6%)

Width & tolerance: 200mm-1650mm (+/-1mm)

Mechanical properties: Tensile strength (U.T.S) ≥ 80 MPA, Elongation ≥ 1%

Standard: GB/T3198/ASTM-B209/EN546

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:Which element contains 3 electrons on the third energy level?

- 3 electrons in the third energy level means it has a configuration of [Ne]3s2 3p1 which corresponds to Aluminum(Al).

- Q:Specifically looking to remember a chocolate cake that came in an aluminium box with a clear plastic cover - it?s quite a large cake and was topped with rich chocolate frostingMy mom called it marble cake but I don?t remember that it was marbled.

- try combining all 3 like this: “No travellers allowed, examine the sign that youthful Papagee Albright observed as he regarded by his binoculars on the ghost cityIt grew to become into sparkling that flowers did no longer many times boost right here and one does no longer locate the widespread scavengers-stray dogs, hungry cats.If actuality, all that the Air tension Captain could see of existence grew to become right into a slithering snake who, in assessment to Albright, had no worry shifting between the rubblePapagee watched the snake slither around the dusty dirt“a minimum of a few thing can stay over there,” he stated, and then, virtually at latest, the snake curled up and died in an unusual way, area of its physique meltedOh my God.however is killing issues over there is quickly appearing and invisible.” His pal, 'Spider Joe’ Jacobs, spoke back, “Invisible to the bare eye, yet once I went around the waters and took soil samples, I observed it by a microscope; an excellent type of tiny crimson specks that blister your epidermisI figured chemicals, yet people who understand mbiologicalt say, 'biologicals.’” grew to become into that helpful? i'm an aspiring author myself.

- Q:Ok, what is it about aluminum that makes it create sparks when it is put in the microwave? Is it made out of something that naturally creates sparks or what?

- You might consider installing radial tire tubes in leaking rimsThis option is for all tire rimsThe aluminum / alloy rims might not hold air properly or be in perfect conditionThe choice is yoursPot holes are a problem with soft metal rimsRemember if one rim gets ruined the replacement cost will exceed the cost of the whole set in this case.Another option is run the custom rims in summer and steel in the winterAuto insurance companies do not cover after market additions to your car in the event of theft.

- Q:Can aluminum foil be put in microwave oven?

- No. The microwave produced by the microwave oven belongs to radio wave frequency band and is about 2500MHz. The features of this frequency band are as follows: 1) It can be absorbed by food and water to make the molecular react violently so as to produce heat. 2) It cannot be absorbed by plastic, ceramic and glass. 3) Metal can be conductive to electricity under the influence of the electric field of microwave. Since thick metal can resist the electric field of microwave and reflect microwave, the inner wall of microwave oven is made by thick metal. Similarly, putting a thick metal container in the microwave oven will make the metal container reflect microwave and thus make the food unheated. However, the electric conduction of thin aluminum foil may cause disastrous reaction. In the course of electric conduction, the temperature of thin metal will rise to cause a fire. At the same time, when met with heat, aluminum foil will shrink and its point will produce sparks which may ignite the combustibles in the oven.

- Q:element or compounddd?

- put some duct tape on it, you dont want to breath in fiberglass it can kill you

- Q:I need something like sandpaper or a grinding disc that will remove things like plastic from aluminum but won't scratch the aluminum. So, sandpaper (or similar) but made out of plastic or maybe soft lead or tin grit so it will scratch plastic but not aluminum.

- Wet and dry use it wet

- Q:Does it matter if I Dnt have wax paper for the pretzels to dry on ?? Just let them dry on a cookie pan Thank you !!

- because it reflects enegy waves

- Q:Hey I want to make some reallly good sweets this weekeend- if everyone could just send their favorite recepie it woudl be great :)Thanks in advance

- How about some homemade butterscotch! It's easy to make and tastes wonderful! Here's the recipe: How to Make Butterscotch Candy Ever have real butterscotch candy? If your only exposure to butterscotch has been through pudding, the bright yellow candies with a chemical taste, or manufactured butterscotch chips, you're in for a much tastier treatHere's how to make the real thing Things You’ll Need: Brown sugar Sugar Light corn syrup Butter Water Vinegar Vanilla extract Heavy saucepan Cookie sheet Aluminum foil Silicone spatula Candy thermometer Glass of ice water Stove Powdered sugar Sharp knife Airtight container Step1 Place 1 cup brown sugar, 1 cup sugar, 1/4 cup corn syrup, 1/2 cup butter, 2 tbsp water, 2 tbspvinegar and 1 tspvanilla into the saucepanStep2 Put the saucepan on the stovetop, and warm the contents over medium heatStep3 Melt the sugar and butter, then reduce the heat until the mixture comes to a medium boilStir with the spatula and scrape the sugar mixture off of the sidesStep4 Heat the mixture until it reaches 300 degrees F on the candy thermometerIf you do not have a candy thermometer, drop some of the hot mixture into a glass of ice waterWhen it has reached about 300 degrees, the mixture will form hard candy balls that crack when dropped into cold waterStep5 Cut a piece of the aluminum foil to fit the cookie sheet and butter generouslyPour the hot candy mixture onto the buttered foil and cool slightlyStep6 Score the top of the candy to form squaresAllow it to cool completelyStep7 Break the candy apart along the scored linesDust with powdered sugar, if desired, to keep them from sticking together, and store in an airtight containerThis method makes a little over 1 lbof butterscotch.

- Q:What are the trends of foil sealing technology?

- Future of food packaging equipment will be accompanied by automatic industry trend toward the efficient, versatile, low consumption of food packaging equipment development, so as to realize improve our overall level of food sealing machine equipment.

- Q:Hi im lexii as you can see and i need different SIMPLE ways to make tilapia filletsgrilled, fried or baked it doesnt matter, you send them in ill try them.

- 15 huh? I think you should just hang out with friends, go to anywhere that seems like fun, or do what i didI went out and I just talked to random people and it was a fun experience.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Painted and Embossed Aluminium Foils Used for Insulated Panels

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords